Nanometer strontium aluminate long-afterglow luminescent materials and preparation method thereof

A luminescent material and nano-aluminum technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of impure products, small size, serious light scattering, etc., and achieve the effects of easy industrial application, simple production process and rich sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

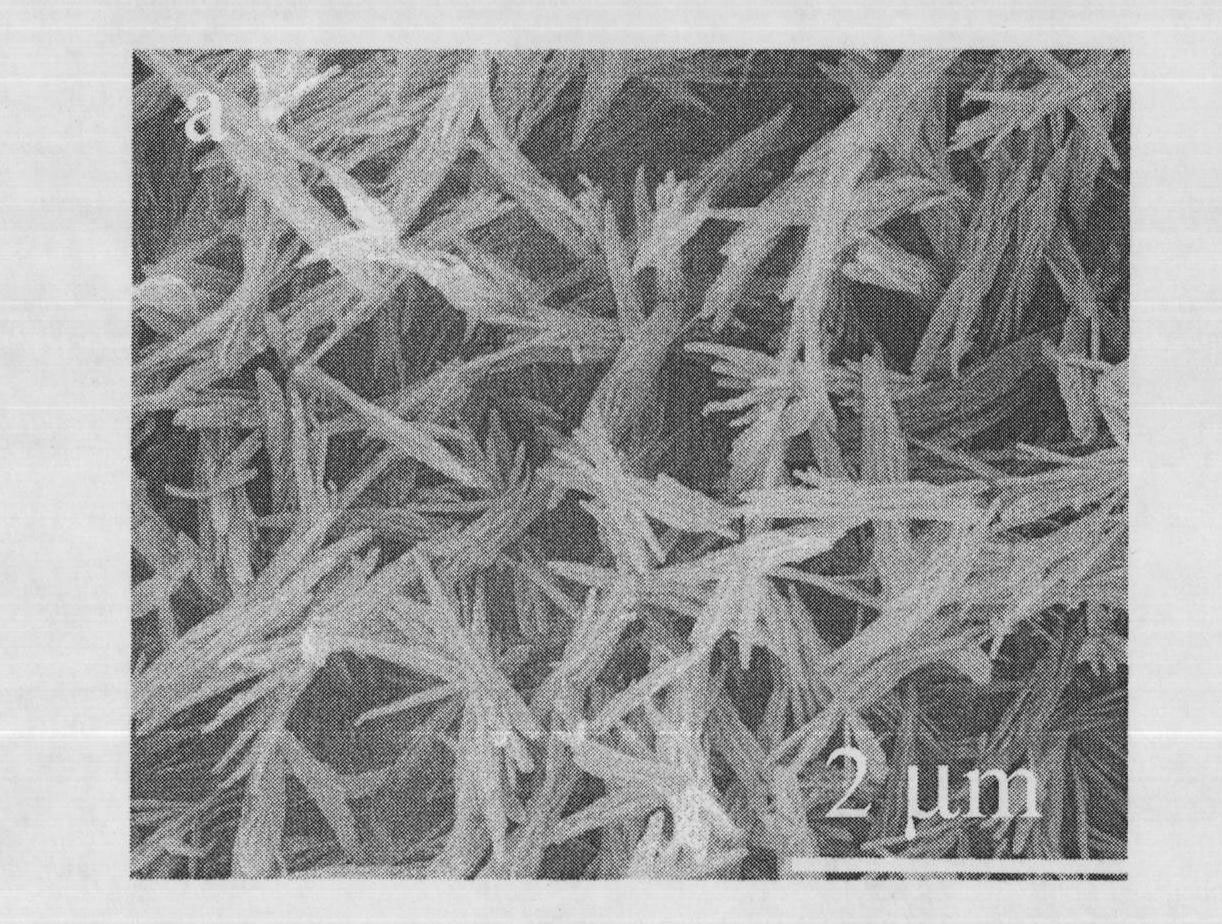

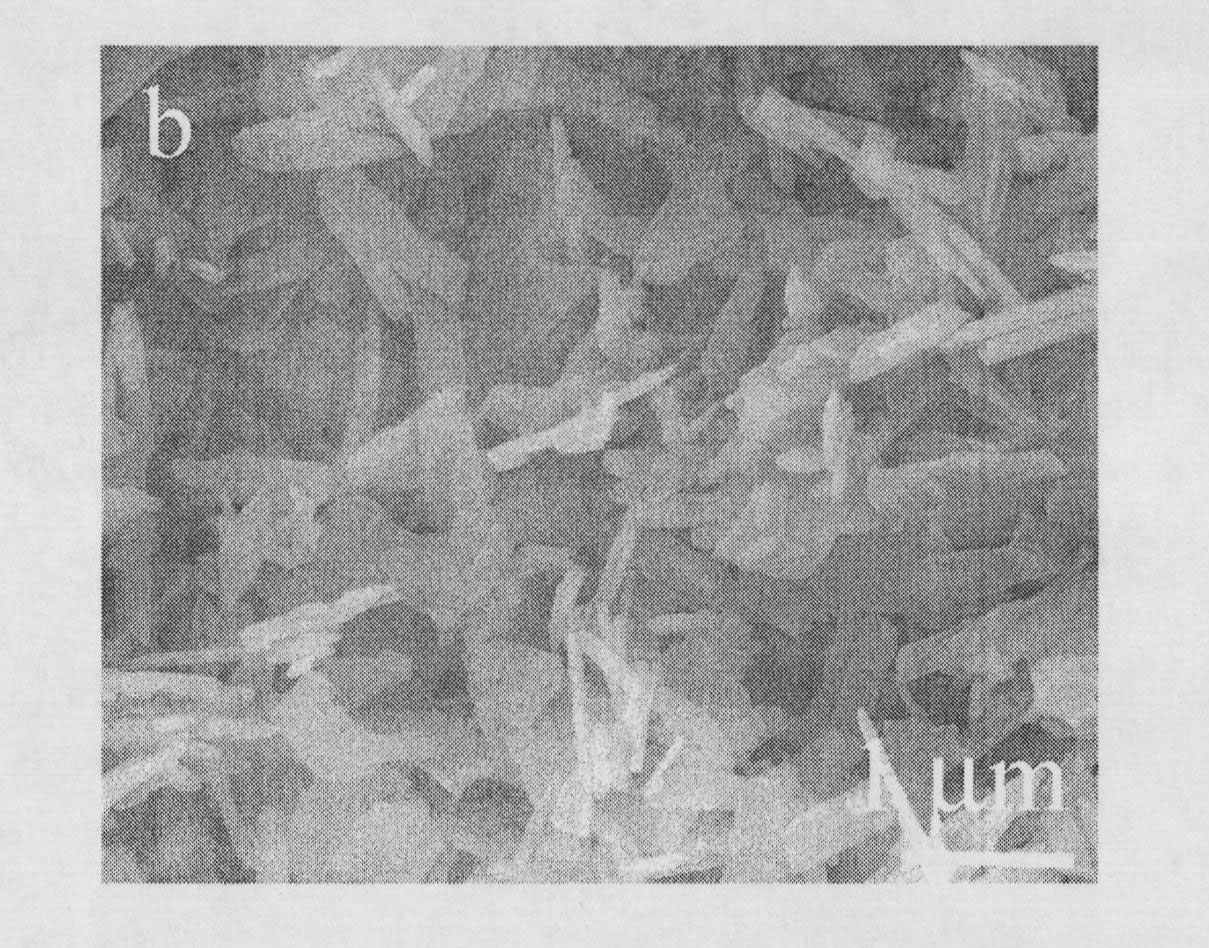

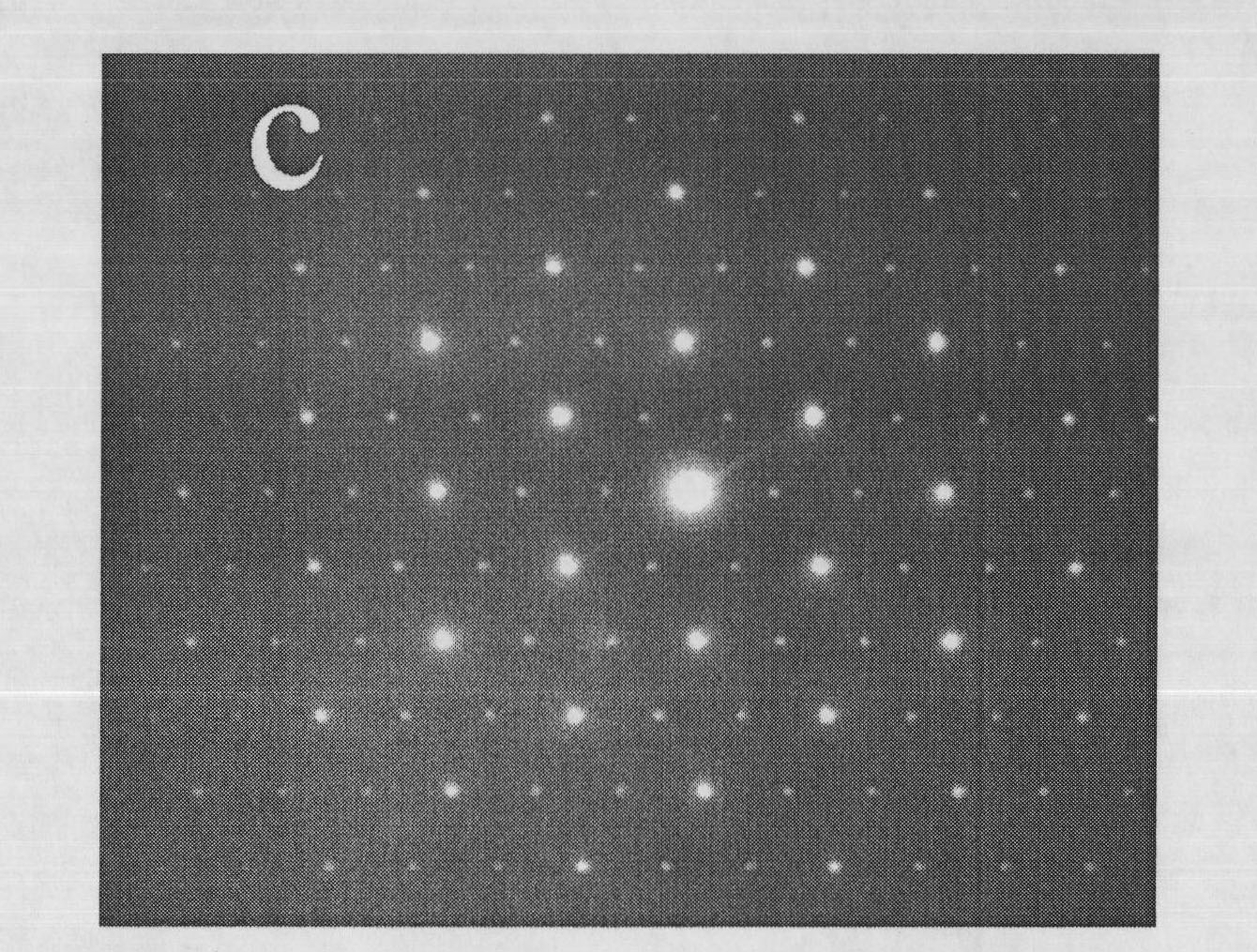

[0031] Long afterglow SrAl 2 o 4 :Eu 2+ , Dy 3+ The preparation process of nanosheet bundle precursor and single crystal nanosheet is as follows, 5 mmol of Sr(NO 3 ) 2 , 10mmol of Al(NO 3 ) 3 9H 2 O, 50 mmol CO(NH 2 ) 2 Dissolve in a beaker filled with 80mL of distilled water, and after magnetic stirring for 5 minutes, add 200μL of Eu(NO 3 ) 3 (0.5M) and 200μL Dy(NO 3 ) 3 (0.5M), after magnetic stirring for 20 minutes, the resulting white suspension was transferred to a 170mL polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and heated at 160°C for 24 hours. After the kettle was cooled to room temperature, A white fluffy product was obtained by centrifugation, washed several times with distilled water and absolute ethanol, and then the white fluffy product was dried at 60° C. under vacuum for 6 hours. available as figure 1 nanosheet bundle precursors. Disperse the obtained precursor in water, add H with a mass fraction of 30% of the precursor...

Embodiment 2

[0034] Long afterglow Sr 0.99 al 2 o 4 :Eu 2+ 0.005 , Dy 3+ 0.005 The preparation process of nanosheet bundle precursor and single crystal nanosheet is as follows, 5 mmol of Sr(NO 3 ) 2 , 10mmol of Al(NO 3 ) 3 9H 2 O, 50 mmol CO(NH 2 ) 2 Dissolve in a beaker filled with 80mL of distilled water, stir magnetically for 5 minutes, then add 50μL of Eu(NO 3 ) 3 (0.5M) and 50μLDy(NO 3 ) 3 (0.5M), after magnetic stirring for 20 minutes, the resulting white suspension was transferred to a 170mL polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and heated at 160°C for 24 hours. After the kettle was cooled to room temperature, A white fluffy product was obtained by centrifugation, washed several times with distilled water and absolute ethanol, and then the white fluffy product was dried at 60° C. under vacuum for 6 hours. Nanosheet bundle precursors are available. Disperse the obtained precursor in water, add H with a mass fraction of 30% of the precu...

Embodiment 3

[0036] Long afterglow Sr 0.90 al 2 o 4 :Eu 2+ 0.05 , Dy 3+ 0.05 The preparation process of nanosheet bundle precursor and single crystal nanosheet is as follows, 5 mmol of Sr(NO 3 ) 2 , 10mmol of Al(NO 3 ) 3 9H 2 O, 50 mmol CO(NH 2 ) 2 Dissolve in a beaker filled with 80mL of distilled water, stir magnetically for 5 minutes, then add 500μL of Eu(NO 3 ) 3 (0.5M) and 500μL Dy(NO 3 ) 3 (0.5M), after magnetic stirring for 20 minutes, the resulting white suspension was transferred to a 170mL polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and heated at 160°C for 24 hours. After the kettle was cooled to room temperature, A white fluffy product was obtained by centrifugation, washed several times with distilled water and absolute ethanol, and then the white fluffy product was dried at 60° C. under vacuum for 6 hours. Nanosheet bundle precursors are available. Disperse the obtained precursor in water, add H with a mass fraction of 30% of the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com