Patents

Literature

110 results about "Lithium stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium stearate is a chemical compound with the formula LiO₂C(CH₂)₁₆CH₃. It is formally classified as a soap (a salt of a fatty acid). Lithium stearate is a white soft solid, prepared by the reaction of lithium hydroxide and stearic acid.

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Special lubricating grease composition for steel wire rope

ActiveCN102250670AImprove water resistanceImprove the protective effectLubricant compositionMicrocrystalline waxLithium 12-hydroxystearate

The invention relates to a special lubricating grease composition for a steel wire rope. The composition comprises the following components in percentage by weight: 2.0-5.2% of lithium 12-hydroxystearate soap, 0.5-1.3% of lithium stearate soap, 53.5-76% of mineral base oil, 15.0-40.0% of extract oil, 1.3-6.3% of microcrystalline wax and 0.2-1.2% of diphenylamine. The lubricating grease provided by the invention has the characteristics that blended base oil containing high-viscosity extract oil is utilized to prepare specific-thickness semi-fluid lubricating grease for the steel wire rope, theadhesion and infiltration capability of the product are improved, and the problems of oil splashing, loss, atmospheric environment pollution and the like of the existing product are solved; and a microcrystalline wax additive is used for improving the water resistance and protective properties of the lubricating grease for the steel wire rope. The lubricating grease provided by the invention has dropping point larger than 165 DEG C, is free of volatile solvent, is convenient for coating, has low production cost and enhanced lubrication effects, and can effectively meet the internal and external lubrication and protection requirements of the steel wire rope during operation.

Owner:CHINA PETROLEUM & CHEM CORP

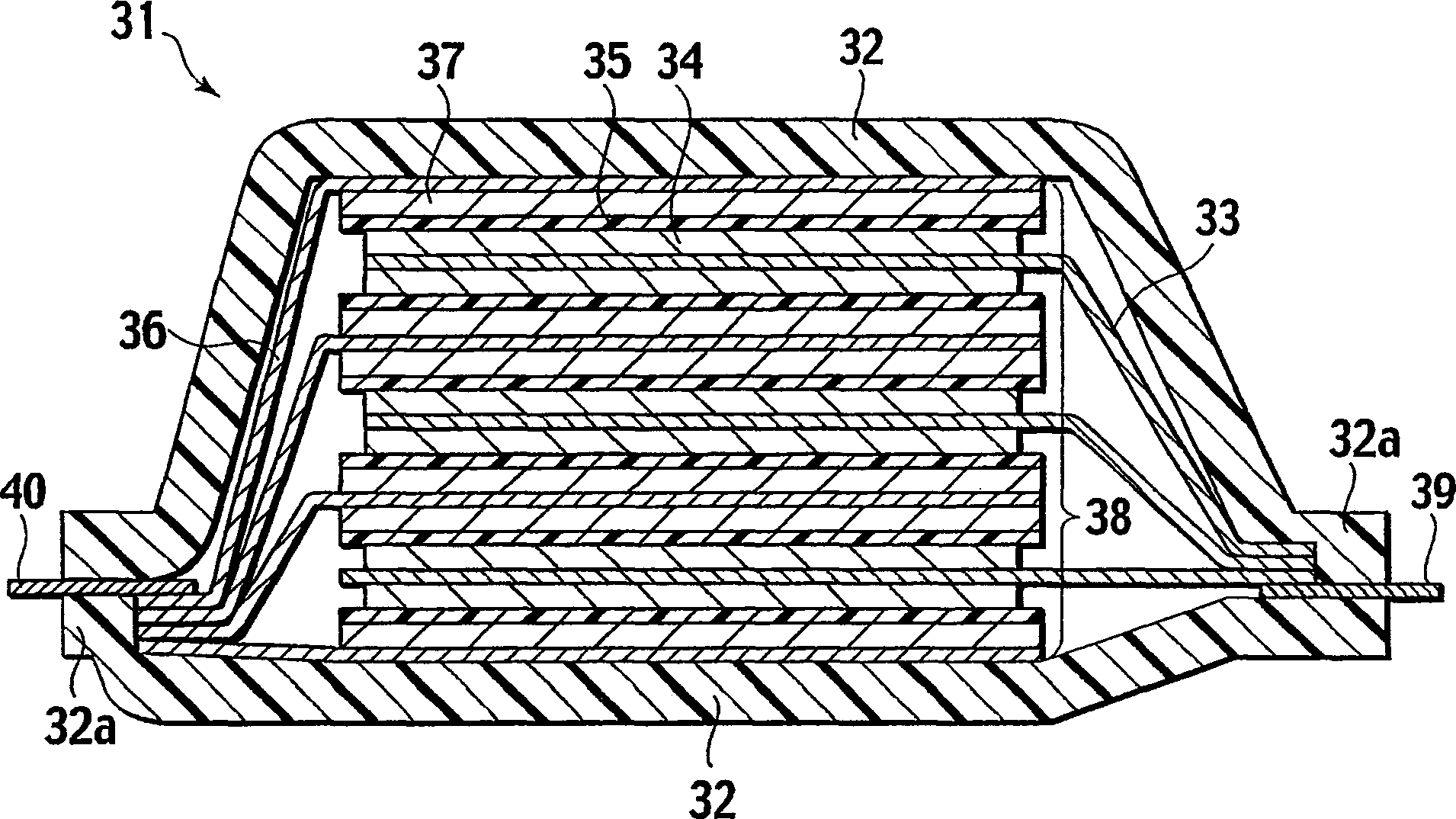

Positive electrode material for non-aqueous electrolyte lithium ion battery and battery using the same

PROBLEM TO BE SOLVED: To provide a positive electrode material for a nonaqueous electrolyte lithium ion battery, which can suppress a decomposition of an electrolyte even when moisture does not enter a cell and a battery is charged or discharged at high temperature.SOLUTION: The positive electrode material for a nonaqueous electrolyte lithium ion battery includes lithium-nickel oxide having a surface covered with an Li compound to be attached. The Li compound is at least one selected from the group consisting of lithium phosphate, an LiPON compound, an Li<SB POS="POST">2< / SB>O-B<SB POS="POST">2< / SB>O<SB POS="POST">3< / SB>compound, an Li<SB POS="POST">2< / SB>O-B<SB POS="POST">2< / SB>O<SB POS="POST">3< / SB>-LiI compound, an Li<SB POS="POST">2< / SB>S-SiS<SB POS="POST">2< / SB>compound, an Li<SB POS="POST">2< / SB>S-SiS<SB POS="POST">2< / SB>-Li<SB POS="POST">3< / SB>PO<SB POS="POST">4< / SB>compound, lithium hydroxide, lithium fluoride, lithium acetate, lithium acetylide ethylenediamine, lithium benzoate, lithium bromide, lithium carbonate, lithium nitrate, lithium oxalate, lithium pyruvate, lithium stearate, lithium tartrate and lithium sulfate.

Owner:ENVISION AESC JAPAN LTD

Coated sand for selective laser sintering (SLS) and preparation method thereof

InactiveCN101823119AHigh activityImprove absorption rateFoundry mouldsFoundry coresEpoxySelective laser sintering

The invention discloses coated sand for selective laser sintering and a preparation method thereof. The coated sand comprises crude sand, a compound binder, a curing agent, a lubricating agent and a light absorber, wherein the compound binder comprises phenolic resin and epoxy resin; the curing agent is formamine; the lubricating agent is zinc stearate, calcium stearate or lithium stearate; and the light absorber is carbon black. The preparation method comprises the following steps: firstly, carrying out freeze grinding on the epoxy resin; then selecting epoxy resin powder with suitable particle size distribution by a sieving method; and finally, evenly mixing a certain ratio of epoxy resin powder, the carbon black and phenolic resin coated sand prepared by the existing process. Due to the fact that the strength of the SLS formed part of the coated sand is higher, the coated sand can be used for SLS of casting sand moulds (cores) with large-size and complicated structures.

Owner:武汉华科三维科技有限公司

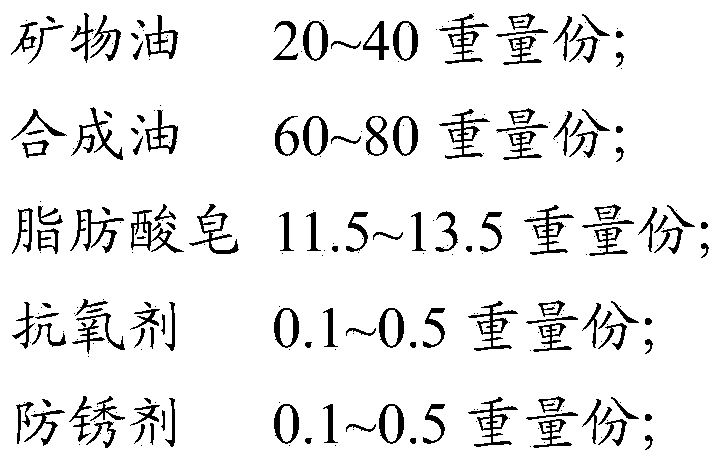

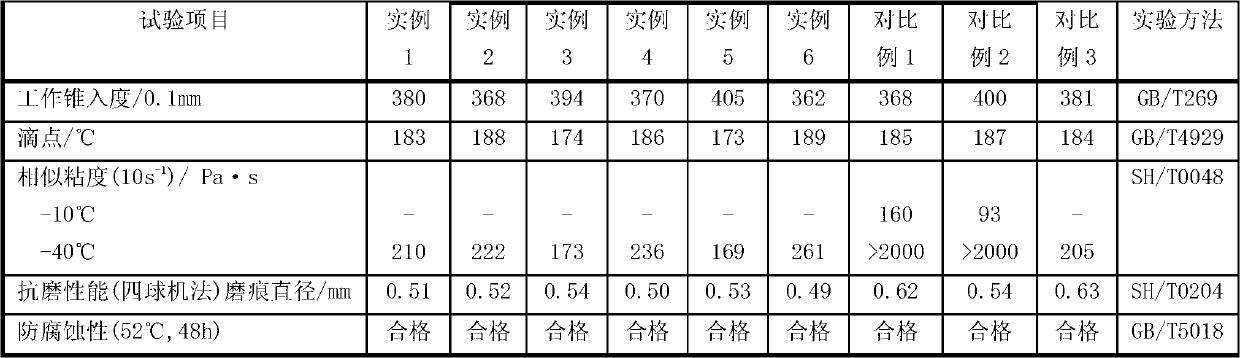

Low-temperature lubricating grease and preparation method thereof

ActiveCN103525510AHigh viscosity indexImprove viscosity indexLubricant compositionAntioxidantEvaporation

The invention provides low-temperature lubricating grease and a preparation method thereof. The low-temperature lubricating grease comprises mineral oil, synthesized oil, fatty acid soap, an antioxidant and an antirust agent. Compared with the prior art, the low-temperature lubricating grease is characterized in that semi-synthesized oil obtained by mixing III-type oil and ester oil and / or PAO (poly alpha olefin) oil is used as basic oil; the III-type oil has a high viscosity index and is high in high-temperature and low-temperature performance, oxidation stability, heat stability and evaporation performance; the ester oil and the PAO oil also have high viscosity indexes and are high in low-temperature performance; moreover, a mixture of lithium stearate and 12-hydroxy lithium stearate is used as a thickening agent for thickening the semi-synthesized oil, so that the low-temperature lubricating grease is high in low-temperature performance, and a used component can be normally lubricated under low temperature; the applicable temperature range is large; furthermore, the thickening agent is easy to synthesize.

Owner:CHINA PETROLEUM & CHEM CORP

Formula and process for powder metallurgy

The invention provides a formula and a process for powder metallurgy. The formula comprises Fe-based powder, machinability improving powder and a free lubricant; the Fe-based powder comprises, by weight, 7 to 14% of copper powder (Cu), 2 to 8% of molybdenum powder (Mo), 0.5 to 3.5% of nickel powder (Ni), 1 to 7% of aluminum powder (Pb), 8 to 16% of graphite (C), 1 to 5.5% of molybdenum disulfide (MoS2), 1.5 to 5% of cast stone, 0.5 to 5% of silicon carbide (SiC) and 4 to 9% of mullite (3Al2O3.2SiO2), with the balance being iron powder, the machinability improving powder is composed of calcium phosphate compounds, and the free lubricant contains at least one selected from the group consisting of thermoplastic resin powder, zinc stearate and lithium stearate.

Owner:王萍

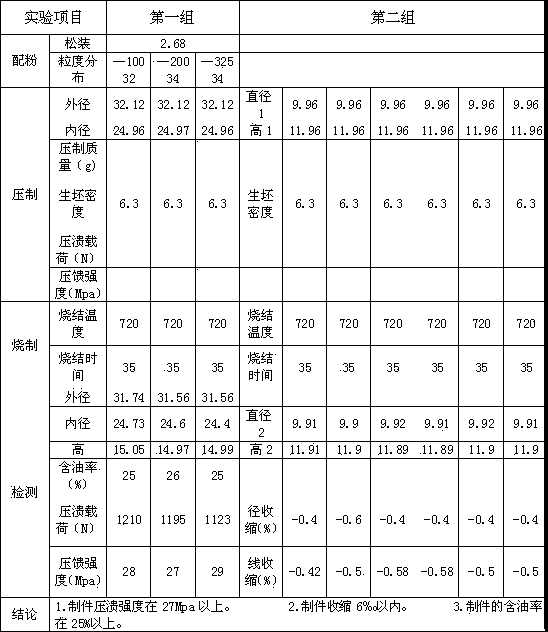

Powder metallurgy Fe-Cu-Sn oil-retaining bearing and manufacturing technique thereof

The invention relates to a powder metallurgy Fe-Cu-Sn oil-retained bearing and the production process for the bearing. The bearing essentially comprises the following raw materials by weight: -100 mesh reduction Fe powder 96.5 swung dash 98%, -325 mesh Cu-Sn powder 2 swung dash 3.5%, lithium stearate 0.6 swung dash 1.0%. Wherein, in Cu-Sn alloy, Cu:Sn=7:2.5 swung dash 3.5 by weight. The production process is: weighing -100 mesh reduction Fe powder, -325 mesh Cu-Sn powder and lithium stearate by proper proportions; mixing them in a double-conic mixer at 19 swung dash 21r / min for 30-35 min; pressing the mixture under 300MPa swung dash 450MPa into blanks for oil-retained bearing; sintering the pressed blanks for 20-30 min under 880 swung dash 900 Celsius system, so sintered blanks are obtained; finishing and soaking by lubricating oil. The invention is of high strength, high oil content, low friction coefficient, low copper content, low material cost and process cost.

Owner:包敢锋

Casting paint for high-chromium cast iron and preparation method thereof

ActiveCN103056289AImprove high and low temperature strengthHigh strengthFoundry mouldsFoundry coresSlagLithium stearate

The invention relates to a casting paint for high-chromium cast iron and a preparation method thereof. The paint comprises the following components in percentage by weight: 15-20% of nano FeCr2O4 composite powder, 3-5% of furnace slag powder, 0.10-0.15% of stearic acid, 3-6% of lithium-base bentonite, 2-3% of silica sol, 5-8% of 3-methyl-2-butenyl-1-ol acetate composite solution and the balance of chrome corundum powder. The furnace slag comprises the following components in percentage by weight: 74-77% of Al2O3, 1-2% of MgO, 19-21% of Cr2O3 and the balance of SiO2. The particle size of the FeCr2O4 composite powder is 80-100 nm, the particle size of the lithium-base bentonite and furnace slag powder is 80-100 mu m, and the particle size of the chrome corundum powder is 1-5 mm. The paint has the advantages of favorable suspensibility, favorable high-temperature strength and no environmental pollution of raw materials.

Owner:MAANSHAN HUADA METALLURGICAL & MACHINERY

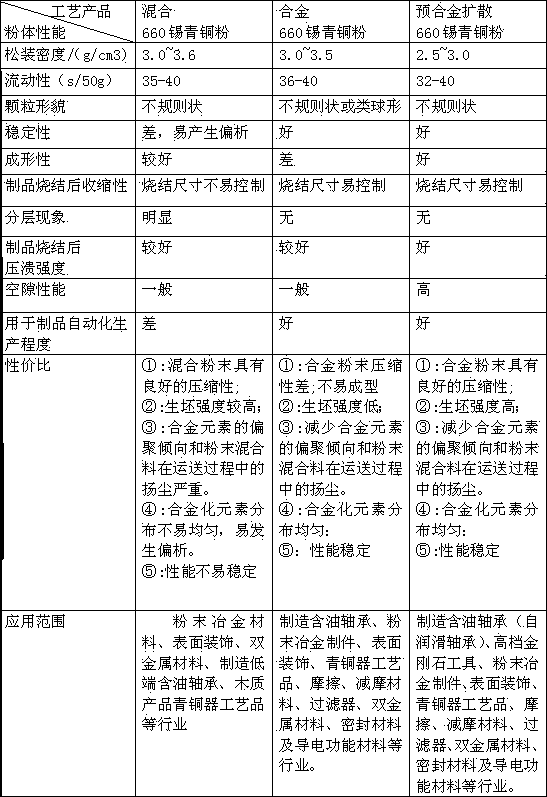

Pre-alloyed diffusion method for producing tin bronze powder

The invention discloses a pre-alloyed diffusion method for producing tin bronze powder. The method comprises the steps as follows: 86%-90% of water atomized pure copper powder smaller than 200 meshes, 5%-7% of zinc powder smaller than 300 meshes and 5%-7% of tin powder smaller than 300 meshes are placed in a V-shaped blending machine for mixing; during a mixing process, lithium stearate and 15%-25% of steel balls are added and blended for 50-70 minutes; and after the mixing is performed, a box type atmosphere furnace is adopted for diffusion sintering at the temperature of 450 DEG C for 30 minutes. With the adoption of the method, during a production process, the stability is good, the forming is easy, the sintering size is easy to control, the layering phenomenon is prevented, the crushing strength of the sintered product is good, and the application range of the finished product is wide.

Owner:安徽明月新铜粉体新材料高科技有限公司

Super environment-friendly coating for abrasive paper, abrasive cloth and abrasive belt and preparation method of coating

InactiveCN103992681AIncrease grinding timeImprove wear resistanceCoatingsWater basedALUMINUM STEARATES

The invention discloses a super environment-friendly coating for an abrasive paper, an abrasive cloth and an abrasive belt and a preparation method of the coating. The coating is prepared from a component I, a component II and a component III, wherein the mass ratio of the component I to the component II to the component III is 50:(200-300):(150-250); by weight percent, the component I comprises 70%-90% of an adhesive and 10%-30% of water, the component II comprises 70%-80% of a heat absorber and 20%-30% of water, and the component III comprises 65%-80% of fillers and 20%-35% of water; the heat absorber adopts one or a mixture of two or more of water-soluble stearic acid, water-based calcium stearate, water-based zinc stearate, water-based aluminum stearate and water-based lithium stearate. The preparation method comprises the following steps: preparing the component I, the component II and the component III respectively, and uniformly stirring according to the ratio. The coating is safe and environmentally friendly, and has an anti-blockage function; the preparation method is simple in flow process and easy to operate.

Owner:洛阳惠尔纳米科技有限公司

High-density non-magnetic steel counterweight part and manufacturing method thereof

ActiveCN106544570ASolve the problem of poor compressionHigh strengthTransportation and packagingMetal-working apparatusElectrolysisHigh density

The invention discloses a high-density non-magnetic steel counterweight part and a manufacturing method of the high-density non-magnetic steel counterweight part. The high-density non-magnetic steel counterweight part comprises, by mass percentage, 6-10% of WC powder, 10% of phosphor copper powder, 15-25% of electrolytic pure copper powder, 1% of a stearic acid lithium lubricant and the balance Fe-Mn-C prealloyed powder. The manufacturing method of the high-density non-magnetic steel counterweight part includes the following steps that (1), the components are weighed according to the mass percentage and uniformly mixed in a mixing machine; (2), the mixed powder uniformly mixed is pressed and formed; and (3), high temperature sintering is performed. The manufacturing method is simple in process, controllable in cost, near-net formed and controllable in dimensional change, and the high-density non-magnetic steel counterweight part with the density of 7.7-7.9 g / cm<3> is manufactured.

Owner:GUANGDONG YUEHAI HUAJIN TECH CO LTD

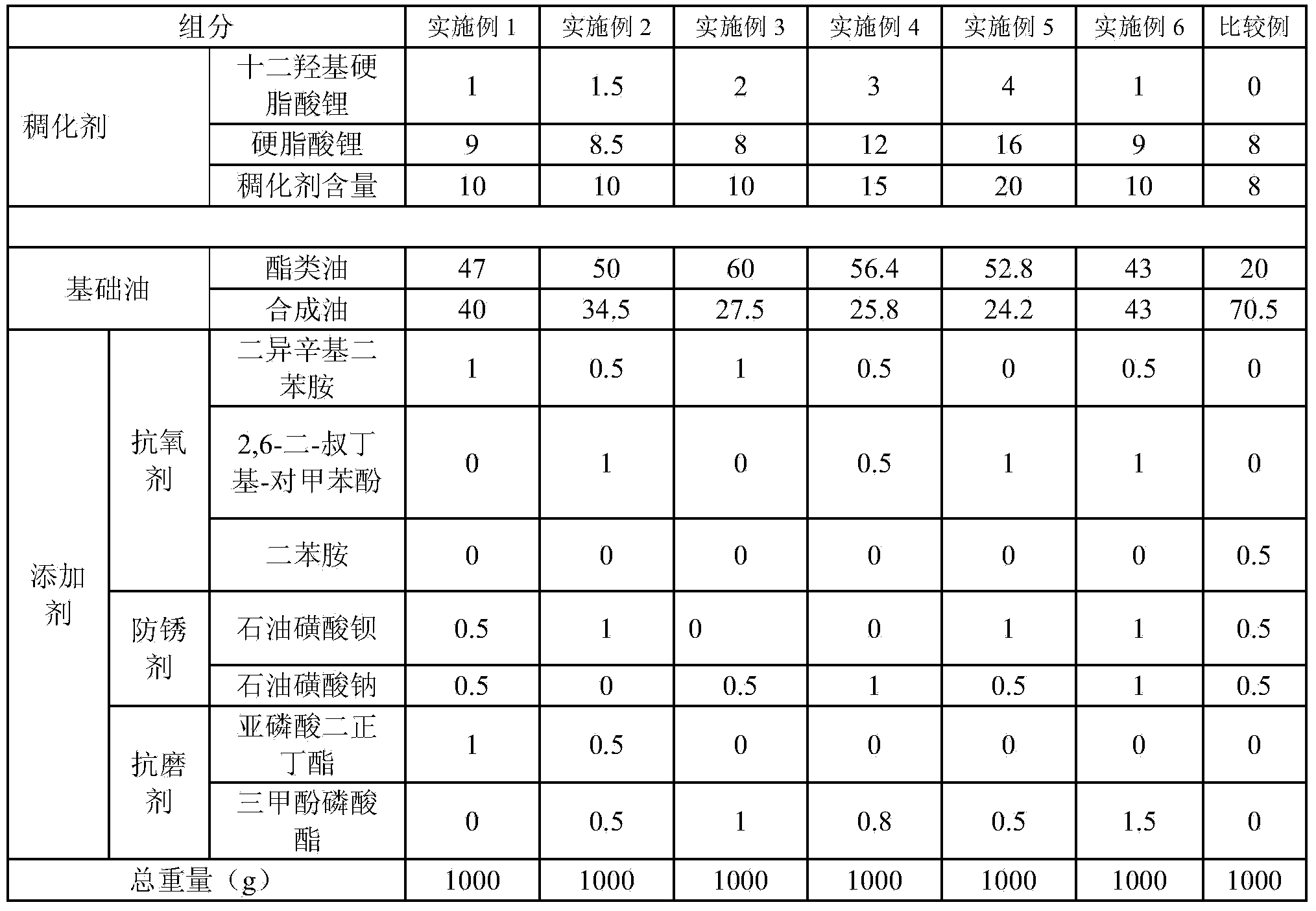

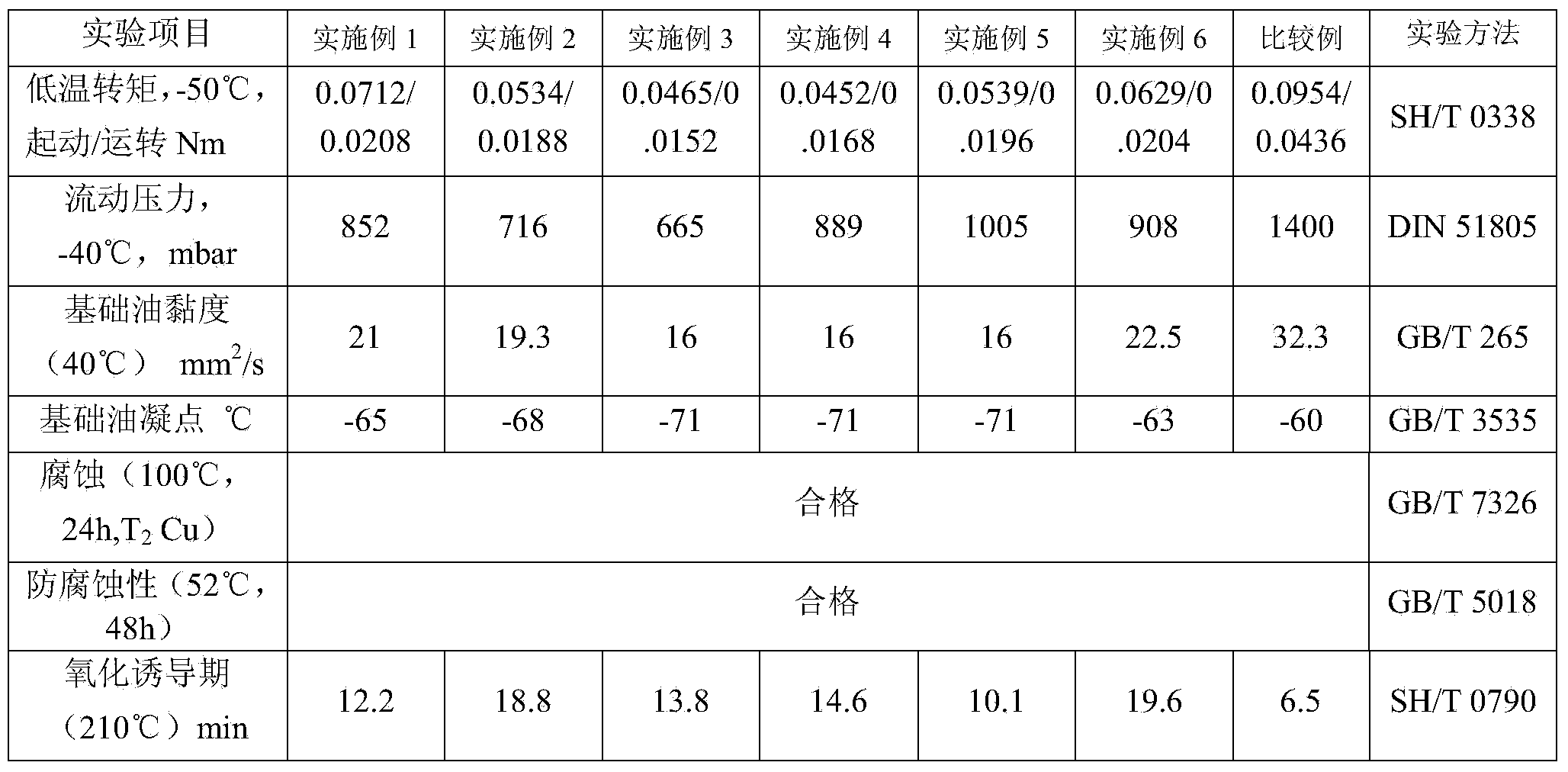

Ultralow-temperature bearing lubricating grease composition and preparation method thereof

InactiveCN104164287AImprove Oxidation StabilityGood starting/running torqueLubricant compositionAfter treatmentAntioxidant

The invention relates to an ultralow-temperature bearing lubricating grease composition and a preparation method thereof. The ultralow-temperature bearing lubricating grease composition comprises 10-20% of a thickener namely lithium 12-hydroxystearate-lithium stearate complex soap, 75-85% of base oil, 0.5-4.0% of an additive (a) namely arylamine and / or phenol antioxidant, 0.5-1.5% of an additive (b) namely a sulfonate rust inhibitor and 0.5-2% of an additive (c) namely a phosphorus antiwear additive. The ultralow-temperature bearing lubricating grease composition comprises the following steps: adding stearic acid into the thickener to react, and adding 12-hydroxystearic acid to react; and adding 1 / 2-2 / 3 of base oil into a reaction kettle, heating to 185-205 DEG C while stirring, adding the rest of base oil, cooling, adding the antioxidant, continuously stirring, naturally cooling to 70-80 DEG C, adding the rust inhibitor and antiwear additive, stirring uniformly, carrying out after-treatment, and canning the finished product. The lubricating grease has favorable oxidation stability; and the lubricating grease has ultralow starting / operating torque, and can ensure the long service life of the lubricating grease and bearing at the ultralow temperature of -60 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-seepage anticorrosive concrete material and preparation method thereof

InactiveCN105084851AHigh compressive strengthImprove impermeabilityCalcium silicatePolyvinyl alcohol

The invention discloses an anti-seepage anticorrosive concrete material and a preparation method thereof. The concrete material consists of the following components in parts by weight: 100-200 parts of portland cement, 30-150 parts of crushed stones, 40-120 parts of fine sand, 10-50 parts of calcium chloride, 8-20 parts of magnesium silicate, 5-16 parts of active calcium silicate, 3-10 parts of sorbose calcium, 3-12 parts of dialuminium hydrogen phosphate, 5-13 parts of strontium oxide, 4-15 parts of brucite powder, 15-35 parts of fly ash, 3-8 parts of white mud powder, 6-18 parts of silica micro powder, 2-10 parts of polyvinyl alcohol, 15-35 parts of phosphorus gypsum, 2-6 parts of 12-hydroxyl lithium stearate, 1-8 parts of potassium tripolyphosphate, 4-9 parts of sodium allylsulfonate, 0.1-4 parts of a water reducing agent, 0.1-3 parts of a swelling agent and an appropriate amount of water. The preparation method of the concrete material is an injection molding method. The anti-seepage level of the concrete material prepared by the method disclosed by the invention is greater than P12 level, the corrosion coefficient is 0.84-0.92, and the anti-seepage level and the corrosion coefficient are higher than those of ordinary concrete; and moreover, the 28-day compression strength of the concrete material is greater than 51.8MPa, which shows that the concrete material prepared by the method disclosed by the invention keeps good compression strength, and the seepage resistance and the corrosion resistance are relatively improved at the same time.

Owner:河南万佳建设工程有限公司

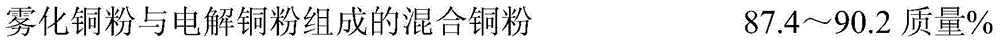

Premixed bronze powder and preparation method and application thereof

The invention provides premixed bronze powder and a preparation method and application thereof. The premixed bronze powder is mainly prepared from the following raw materials in percentage by mass: 87.4-90.2% of mixed copper powder prepared from atomized copper powder and electrolytic copper powder, 9-11% of tin powder, 0.4-0.8% of zinc stearate and 0.4-0.8% of lithium stearate. The preparation method comprises the steps of preparing the atomized copper powder through high-pressure water atomization, then, mixing the atomized copper powder with the electrolytic copper powder, carrying out high-temperature sintering so as to agglomerate, crushing, sieving, and mixing the mixed copper powder with the tin powder, zinc stearate and lithium stearate, thereby obtaining the premixed bronze powder. According to the premixed bronze powder provided by the invention, the loose specific weight is 2.5-2.8g / cm<3>, the particle size distribution is -100 to -325 meshes, and an oil-retaining bearing manufactured from the premixed bronze powder has the oil content reaching 30-35%, the contraction ratio of -0.2% to 0.5% and the crushing strength of 30,000psi and can meet the requirements of technologies and markets.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Extreme-pressure anti-wear lubricating agent

InactiveCN104450143ALow high temperature coefficient of frictionImprove the lubrication effectLubricant compositionCelluloseSodium tetrafluoroborate

The invention provides an extreme-pressure anti-wear lubricating agent, and relates to the technical field of high-temperature lubricating agents. The extreme-pressure anti-wear lubricating agent comprises components in weight ratio as follows: 0.1%-3% of a component A, 8%-35% of a component B, 2%-6% of a component C, 0.5%-5% of a component D, 0.5%-4% of a component E, 0.5%-4% of a component F, 0.8%-4% of a component G, 0.2%-1% of a component H and the balance of water, wherein the component A is one of or a mixture of sodium carboxymethylcellulose and xanthan gum; the component B is one of or a mixture of talc powder and bentonite; the component C adopts sodium silicate; the component D adopts one of or a mixture of two or three of sodium fluoborate, borax decahydrate and calcium metaborate; the component E adopts one of zinc stearate and lithium stearate; the component F adopts one of nano fullerene and alkaline sulfonate; the component G adopts sodium polyacrylate; and the component H adopts a water-based defoaming agent. The high-temperature friction coefficient value is very low, the lubricating property is excellent, and the lubricating requirement of current equipment under the high-temperature and high-load conditions can be well met.

Owner:NANHUA UNIV +1

Impact resistant rigid vinyl chloride polymer composition and method of making the same

InactiveUS20090093577A1Synthetic resin layered productsLiquid carbonaceous fuelsAluminum StearateAlpha-olefin

The instant invention is an impact resistant rigid vinyl chloride polymer composition, and method of making the same. The impact resistant rigid vinyl chloride polymer composition, according to instant invention, includes a vinyl chloride polymer, an impact modifier, and a lubricant system. The impact modifier includes a chlorinated olefin polymer, and an ethylene / alpha-olefin copolymer. The lubricant system includes a first component, a second component, and a third component. The first component is a carboxylic acid selected from the group consisting of stearic acid, lauric acid, myristic acid, palmitic acid, blends thereof, and combinations thereof. The second component is a hydrocarbon wax selected from the group consisting of a paraffin wax, polyolefin wax, blends thereof, and combinations thereof. The third component is a metal soap selected from the group consisting of calcium stearate, aluminum stearate, copper stearate, lithium stearate, magnesium stearate, sodium stearate, zinc stearate, blends thereof, and combinations thereof. The process for preparing the impact resistant rigid vinyl chloride polymer composition of the instant invention includes the following steps: (1) providing a vinyl chloride polymer; (2) providing an impact modifier as described above; (3) providing a lubricant system as described above; (4) blending the vinyl chloride polymer, the impact modifier, and the lubricant system thereby forming the impact resistant rigid vinyl chloride polymer composition.

Owner:DOW GLOBAL TECH LLC

Lithium-based lubricating grease composition and preparation method for same

InactiveCN103525503AImprove structural stabilityIncrease frictionBase-materialsLithium 12-hydroxystearateLithium stearate

The invention provides a lithium-based lubricating grease composition and a preparation method for the lithium-based lubricating grease composition. The lithium-based lubricating grease is prepared by saponifying special high-acid value mineral base oil. The preparation method comprises the following steps of putting the high-acid value mineral base oil into a kettle, adding 12-lithium hydroxyl-stearate soap and lithium stearate soap, and performing stirring and heating; when temperature rises to 210 to 220 DEG C, keeping the temperature, and performing stirring for 1 to 5 minutes; putting ordinary mineral base oil into the kettle, quickly cooling the materials, and adding an additive when the temperature reaches 140 to 150 DEG C; uniformly stirring the materials, and discharging the materials from the kettle; grinding the materials to obtain a finished product by using a three-roller grinding machine. According to the lubricating grease composition, conventional base oil resources in China are reasonably utilized instead of a naphthenic acid raw material, so that the production cost of the lubricating grease is remarkably lowered; the lubricating grease has high mechanical stability, colloid stability and lubricating performance, and the friction and abrasion conditions of mechanical equipment during operation can also be effectively improved; the produced lubricating grease can be used for lubricating automobiles, construction machinery and other mechanical equipment.

Owner:CHINA PETROLEUM & CHEM CORP

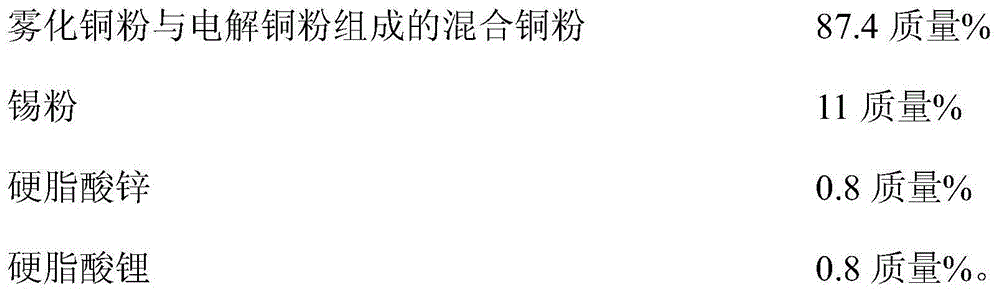

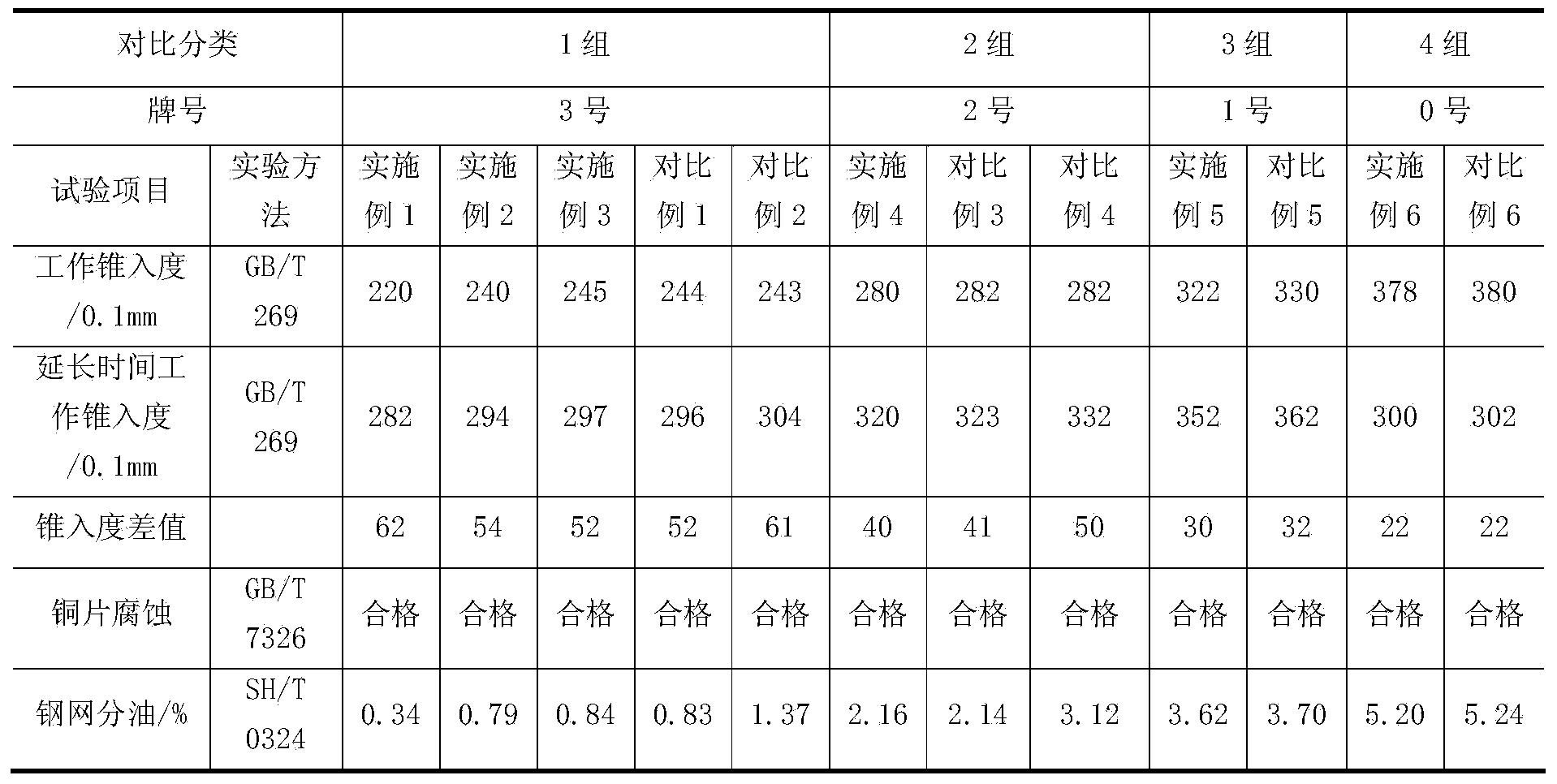

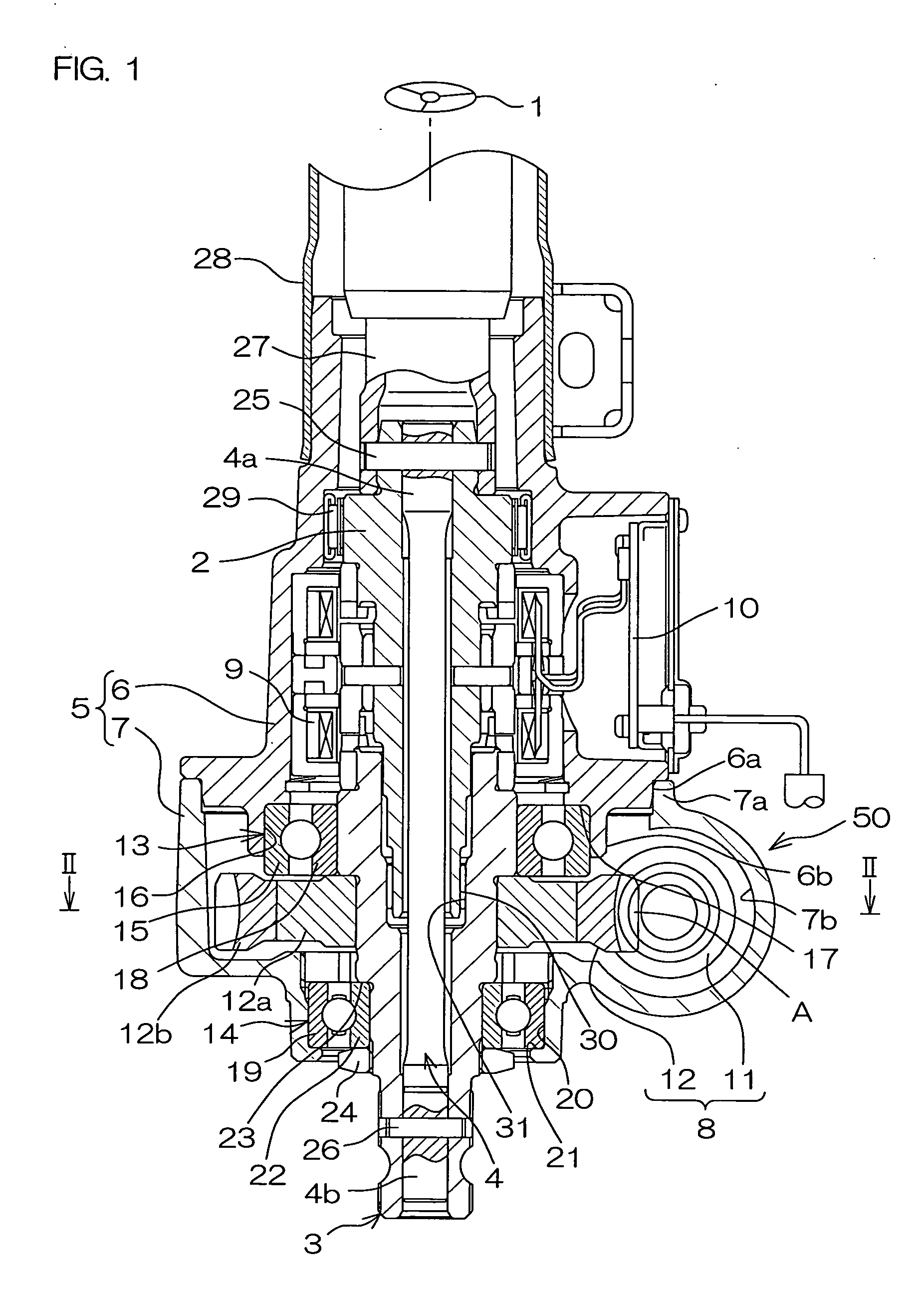

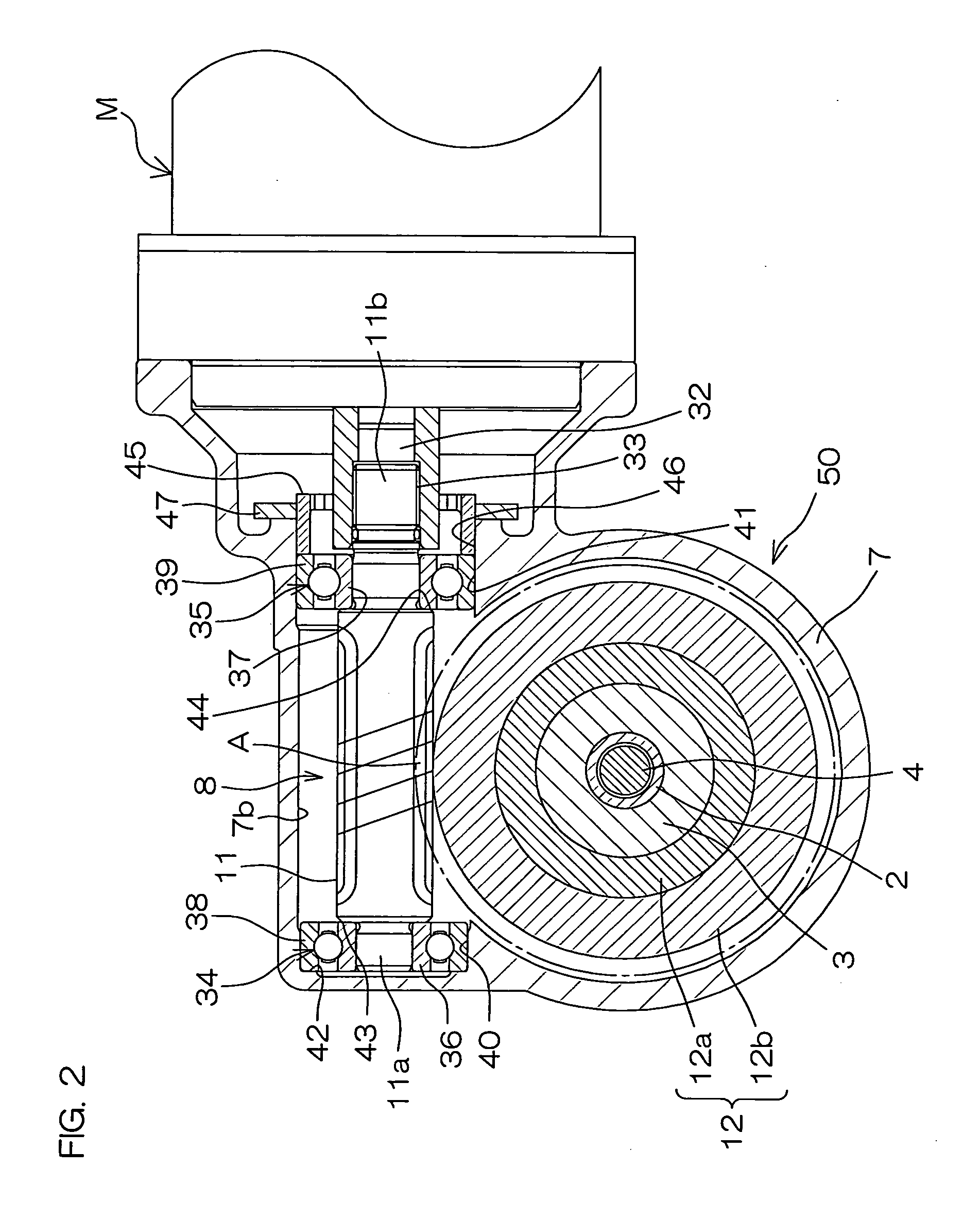

Lubricant Composition, Speed Reduction Gear Employing the Composition, and Electric Power Steering Apparatus Employing the Speed Reduction Gear

InactiveUS20090283353A1Reduce noiseGear lubrication/coolingThickenersElectric power steeringGear wheel

A novel lubricant composition is provided, which is free from an increase in consistency, separation of its lubricant base oil, and leakage of the separated lubricant base oil from a speed reduction gear or the like even if a stress is repeatedly applied to the composition over a long period of time. A speed reduction gear employing the lubricant composition, and an electric power steering apparatus are also provided. The lubricant composition employs at least two types of thickeners including lithium stearate in combination, and has a worked penetration of not less than 355 (at 25° C.). The speed reduction gear 50 is filled with the lubricant composition containing minute particles, and the electric power steering apparatus includes the speed reduction gear.

Owner:JTEKT CORP

Wire rope lubricating grease composition used in low temperature environment

InactiveCN102827670AReduce wearExtended service lifeLubricant compositionLithium soapLithium stearate

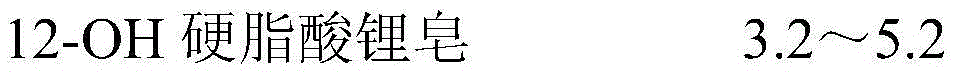

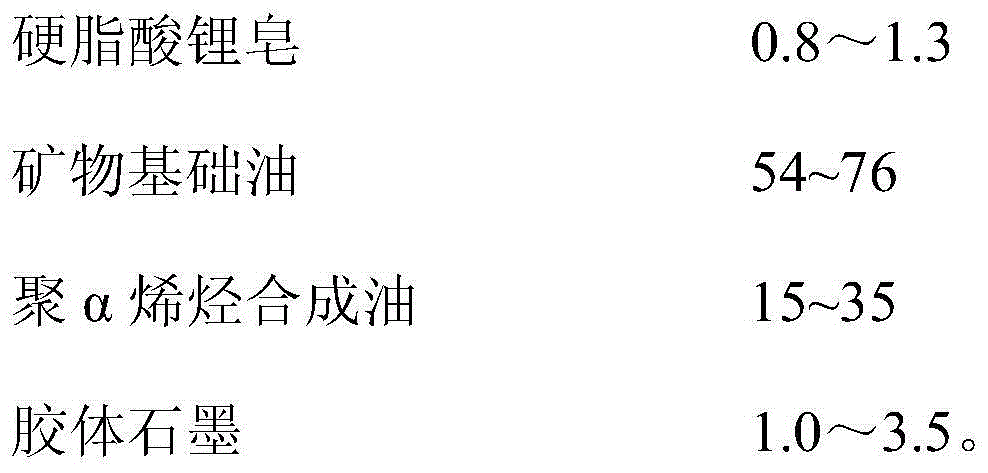

The invention relates to a wire rope lubricating grease composition used in low temperature environment. The composition comprises the following components by percentage: 3.2 to 5.2 % of 12-OH lithium stearate soap, 0.8 to 1.3 % of lithium stearate soap, 85 to 92.5 % of poly-alpha-olefin synthetic oil, 2.5 to 5.0 % of high-base number synthetic calcium and 1.0 to 3.5 % of colloid graphite. The invention is characterized by using the poly-alpha-olefin synthetic oil with excellent low temperature performance as base oil, and using a mixture of the high-base number synthetic calcium and the colloid graphite as an antifriction agent, thereby obtaining the novel semifluid wire rope lubricating grease with fatty acid lithium soap as a densifier. The product has excellent low temperature resistance, solves problems of greased difficulties in low temperature environment, easy embrittlement, falling off and grease throwing of present products, and can be applied to lubricate wire rope apparatus of various construction machineries at operating sites of domestic northern mines. Service temperature range of the composition is from -40 to 80 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Water-borne inorganic anti-corrosive paint added with lithium stearate

InactiveCN105001688ASimple preparation processImprove stabilityAlkali metal silicate coatingsAnti-corrosive paintsEmulsionLithium stearate

The invention relates to water-borne inorganic anti-corrosive paint added with lithium stearate serving as a stabilizer. A preparation method of the paint comprises the steps that an appropriate amount of sodium silicate solution is taken and poured into a vessel which can be heated, slow heating is conducted through a heat source, when the temperature rises to about 70 DEG C, silicone acrylic emulsion is added into the vessel, heating is stopped after the mixture is thoroughly mixed, a titanate coupling agent and zinc powder are sequentially added, stirring is accelerated for mixing, a MgC12 aqueous solution and the lithium stearate serving as a stabilizer are added at last, and the water-borne inorganic anti-corrosive paint added with the lithium stearate is obtained after the mixture is evenly mixed. The prepared paint is good in stability performance, the preparation technology is simple, and the water-borne inorganic anti-corrosive paint added with the lithium stearate has better application prospect.

Owner:严致迪

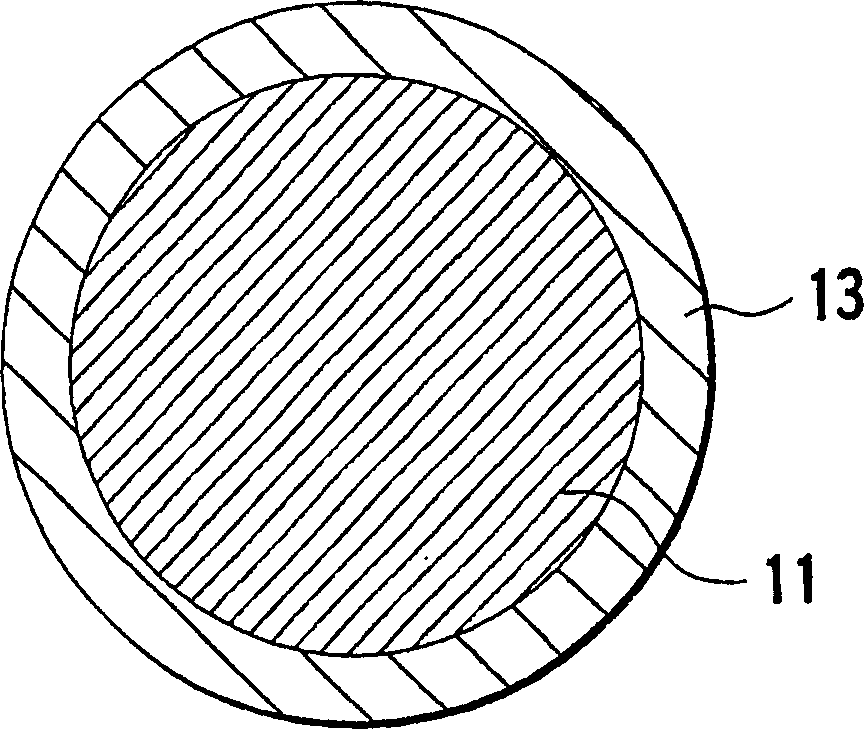

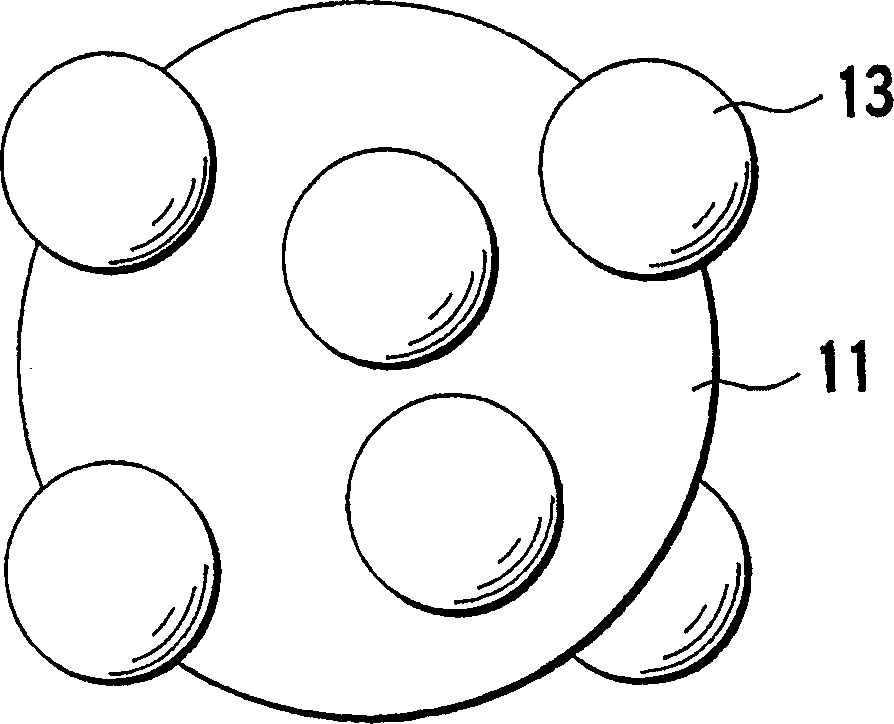

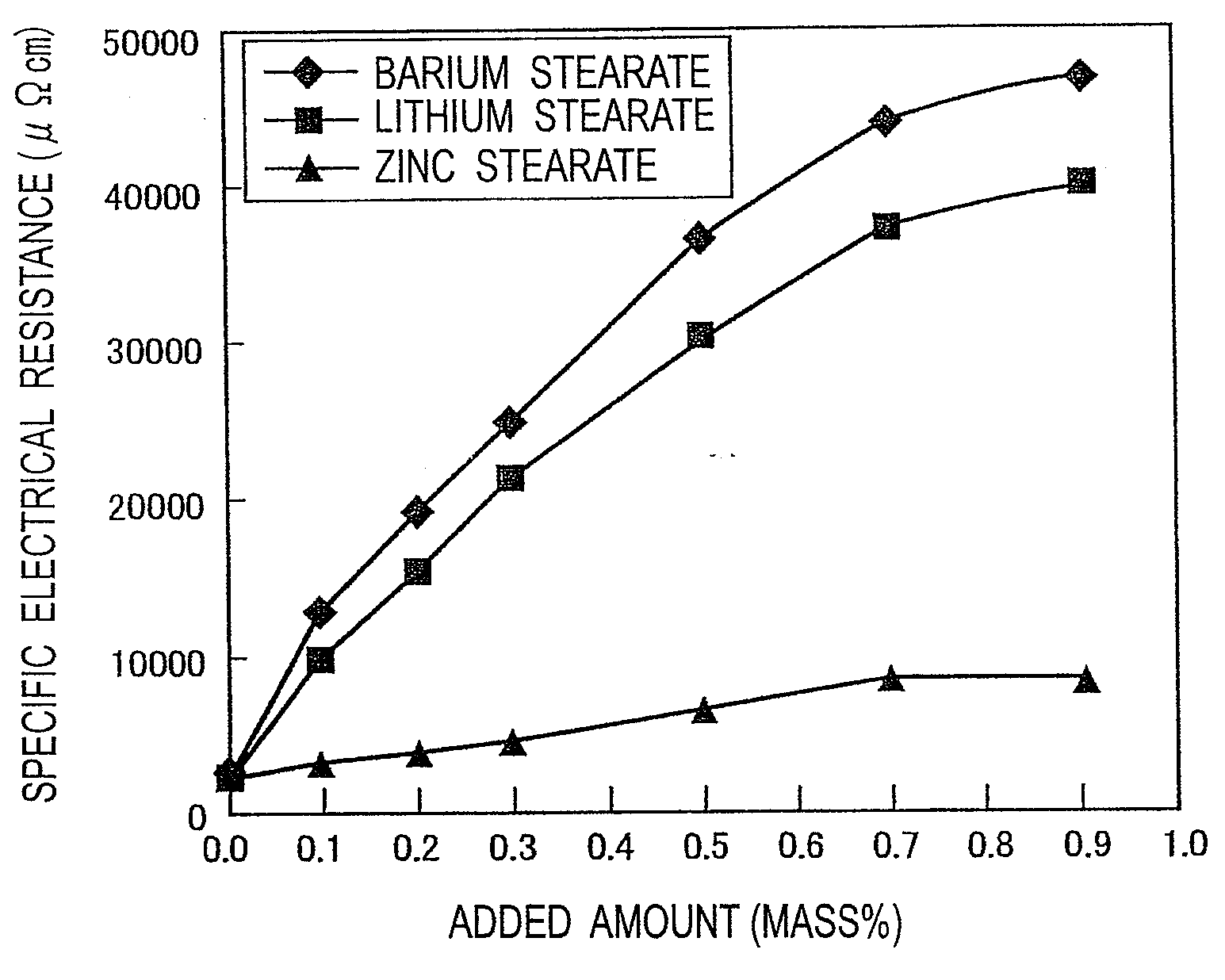

Soft magnetic powdered core and method for producing same

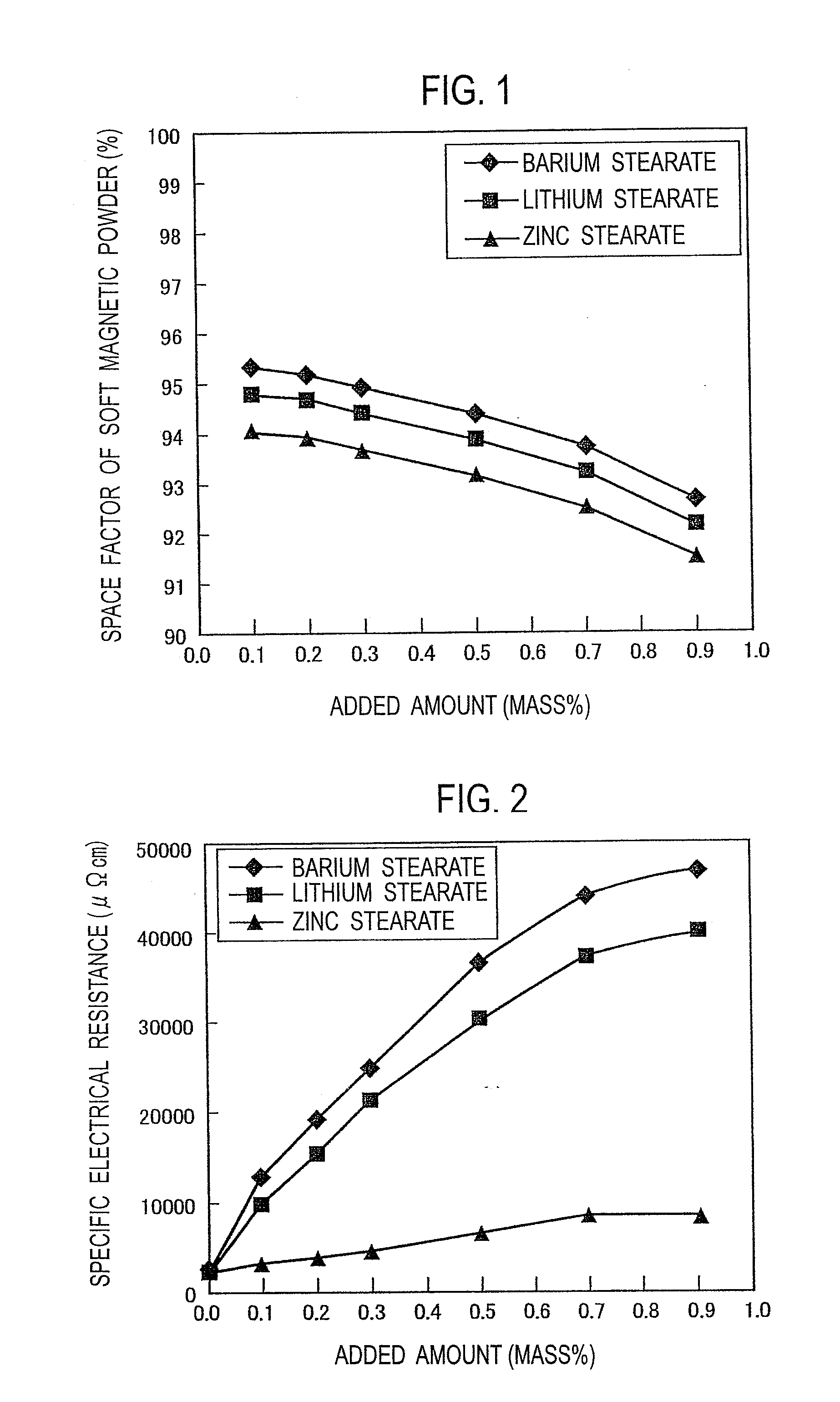

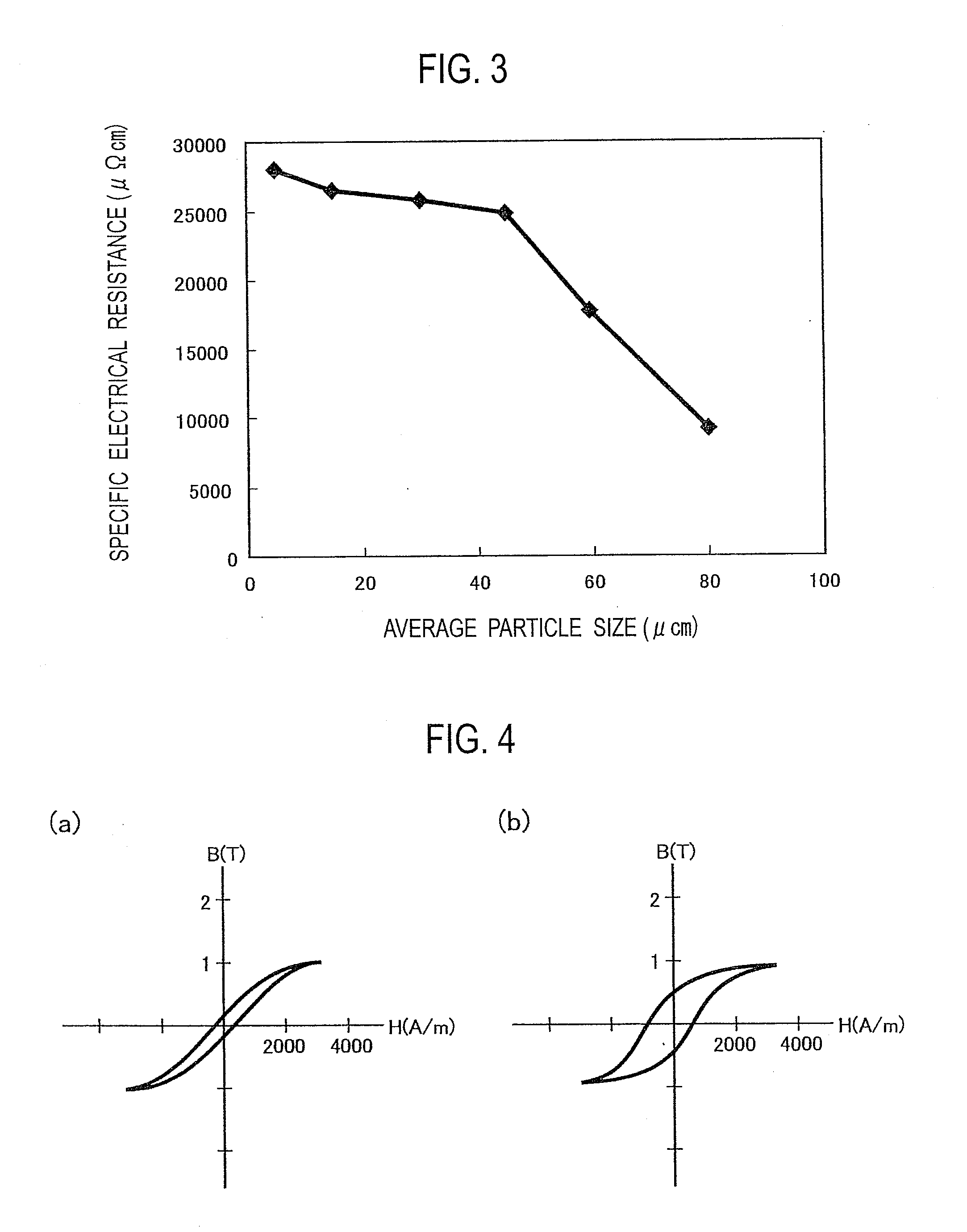

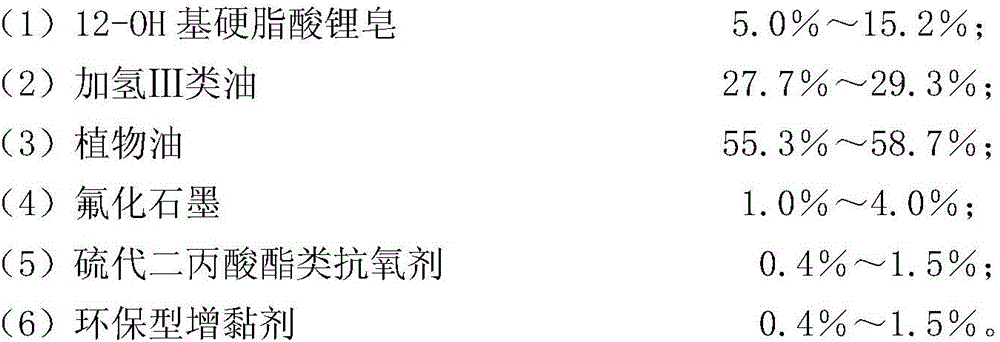

ActiveUS20120119134A1Impaired electrical insulation propertySuitable magnetic propertyTransportation and packagingMetal-working apparatusElectrical resistance and conductancePowder mixture

A powder mixture, which contains a soft magnetic powder and an insulating powder lubricant in an amount of 0.1% by mass or more relative to the soft magnetic powder, is formed by compacting at a compacting pressure of 800 MPa or less, thereby obtaining a powder compact that has a space factor of the soft magnetic powder of 93% or more. The powder compact can be used as a soft magnetic powdered core. The soft magnetic powdered core has a specific resistance or 10,000 μΩcm or more. A powder of a metal soap such as barium stearate or lithium stearate is used as the insulating powder lubricant.

Owner:RESONAC CORP

Method for recovering lithium in mother liquor of process for producing lithium carbonate from spodumene through sulfuric acid process

InactiveCN103964474ASolving Recycling ProblemsSolve quality problemsLithium carbonates/bicarbonatesLithium sulfates/sulfitesLithium sulphateRecovery method

The invention discloses a method for recovering lithium in mother liquor of a process for producing lithium carbonate from spodumene through a sulfuric acid process. The method is used for solving the problems that second-grade lithium carbonate and first-grade lithium carbonate are low in yield, and soluble impurities (SO4<2->, K<+> and Cl<->) in the mother liquor return to the system to affect the product quality in a method for recovering lithium in the lithium carbonate mother liquor in the prior art. The method disclosed by the invention mainly comprises the steps: concentrating lithium carbonate mother liquor; reacting to generate lithium stearate and separating the lithium stearate; and reacting to produce lithium sulfate and conveying the lithium sulfate to a lithium sulfate liquid storage tank. The method solves the problems of recovery of lithium in the lithium carbonate mother liquor and product quality, increases the yield of first-grade lithium carbonate, prevents the soluble impurities (SO4<2->, K<+> and Cl<->) from returning to the system and guarantees the product quality.

Owner:甘孜州泸兴锂业有限公司

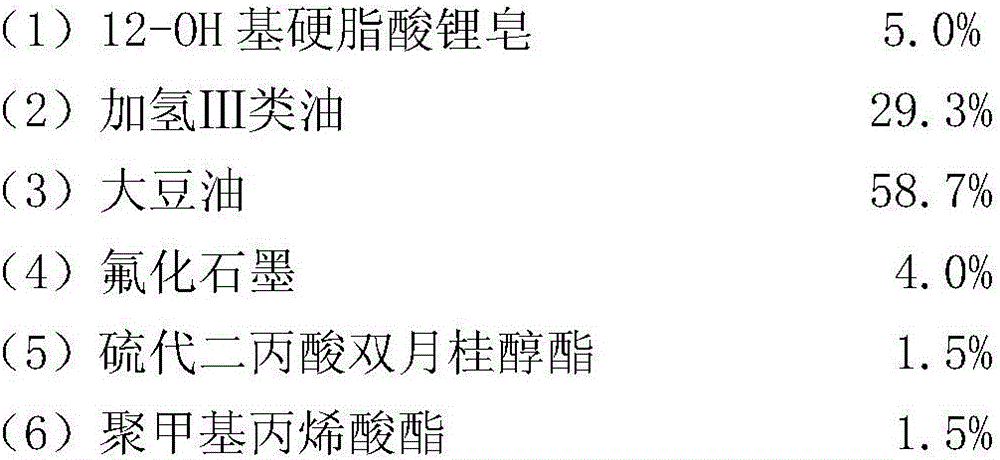

Highly biodegradable construction machinery lubricating grease and preparation method thereof

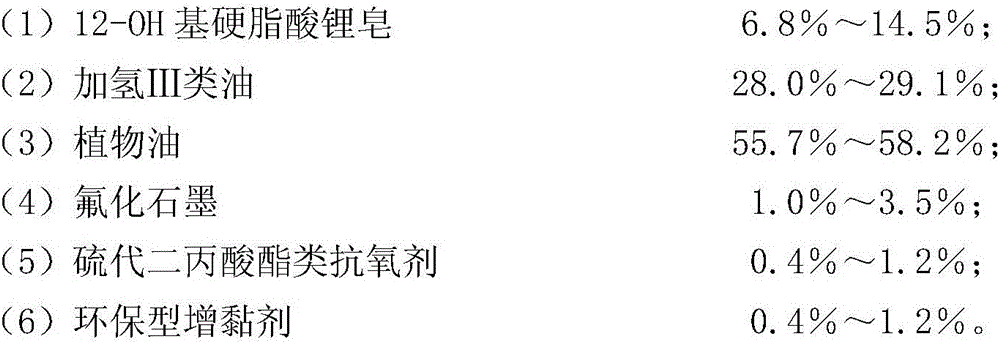

ActiveCN106497651AExtended service lifePromote degradationLubricant compositionCarbon monofluorideVegetable oil

The invention relates to highly biodegradable construction machinery lubricating grease and a preparation method thereof. The grease is prepared from, by weight percentage, 5.0-15.2% of 12-OH lithium stearate soap, 27.7-29.3% ofcategory III hydrogenated oil, 55.3-58.7% of vegetable oil, 1.0-4.0% of carbon monofluoride, 0.4-1.5% of thiodipropionic acid anti-oxidant and 0.4-1.5% of environmental friendly tackifier. The preparation method comprises the steps of mixing the vegetable oil thickened by the 12-OH lithium stearate soap and the category III hydrogenated oil based on the proportion, adding friction reducing agent, anti-oxidant and tackifier to acquire the grease. The grease is suitable for the lubrication of various construction machinery used in a portable water construction, golf course and other situations where environmental pollution is strictly forbidden. The grease can considerably reduce the pollution to the natural environment due to the lubrication oil leakage in construction, improve lubrication condition of construction machinery, and satisfy the machinery's requirement for the lubrication grease service period.

Owner:CHINA PETROLEUM & CHEM CORP

Isotropic bonded rare earth permanent magnetic material and preparation method thereof

The invention discloses an isotropic bonded rare earth permanent magnetic material and a preparation method of the isotropic bonded rare earth permanent magnetic material. The permanent magnet material comprises, by weight, 84-94% NdFeB magnetic powder, 5-15% of nylon and 0.1% -1.0% of lubricant. The preparation method comprises the following steps that the NdFeB magnetic powder, nylon 6 and nylon 12 are selected according to a proportion, and are placed into a ball mill and sieved and crushed; the raw materials are poured into a mixing machine to be mixed and stirred; the raw materials are poured into an internal mixer to be internally mixed and squeezed, and lithium stearate is added; the raw materials are poured into a granulator to be diced; the raw materials are put into an oven to be dried; the raw materials are injected into a mold though an injection machine to be formed. The isotropic bonded rare earth permanent magnetic material and the preparation method of the isotropic bonded rare earth permanent magnetic material have the advantages that the weight of injection molding magnetic remanence Br is larger than or equal to 6.75kGs, the intrinsic coercivity Hcj is larger than or equal to 8kOe, and the maximum energy product is larger than or equal to 8MGOe; due to the isotropic bonded rare earth permanent magnetic material and the preparation method of the isotropic bonded rare earth permanent magnetic material, the annual capacity of isotropic bonded magnet injection molding production lines can reach 20 tons or more.

Owner:海美格磁石技术(深圳)有限公司

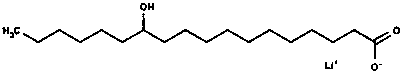

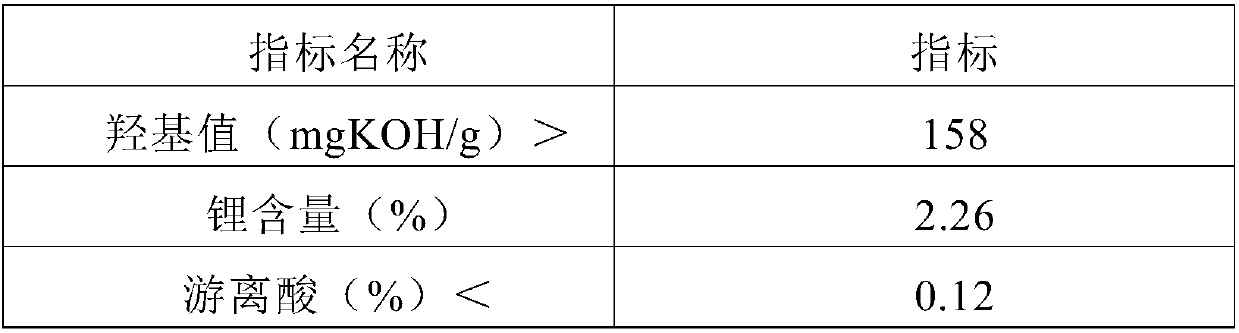

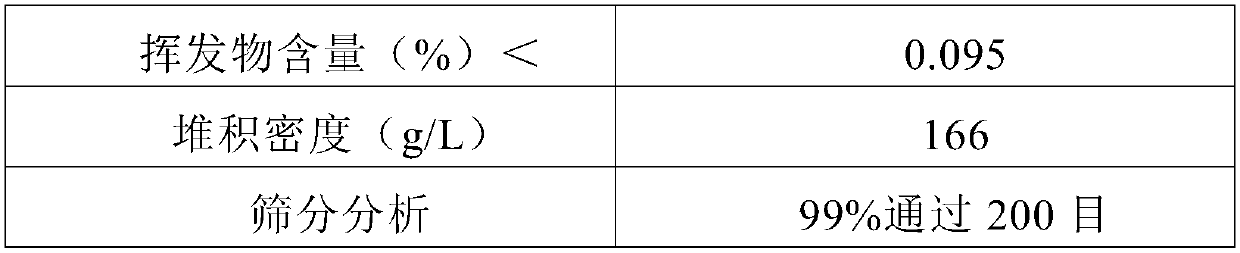

Preparation method of lithium 12-hydroxystearate

InactiveCN107840788AReduce free acidHigh purityOrganic compound preparationCarboxylic acid salt preparationEmulsionLithium 12-hydroxystearate

The invention discloses a preparation method of lithium 12-hydroxystearate. The method comprises the following steps: A. mixing 12-hydroxystearic acid with water, then heating up to 90-100 DEG C, andmaintaining the constant temperature for 40-60min to obtain a 12-hydroxystearic acid solution; B. mixing lithium hydroxide monohydrate with water to prepare a lithium hydroxide solution with a concentration of 2.5-10%, heating up to 80-90 DEG C, and maintaining the constant temperature for 15-30min; C. adding the lithium hydroxide solution into the 12-hydroxystearic acid solution, maintaining thetemperature to be 90 DEG C or above, carrying out a neutral reaction, and stirring for carrying out a reaction for 40-60min; D. after the reaction is finished, carrying out an emulsion reaction for 15-30min; E. after emulsification is finished, carrying out centrifugal dewatering, and carrying out elution on the product with hot water at the temperature of 90 DEG C or above until the pH value of the washing liquid is 8-9 so as to obtain a lithium 12-hydroxystearate wet material; F. drying the lithium 12-hydroxystearate wet material to obtain a dry material; G. crushing the dry material to obtain the finished product. The preparation method of the lithium 12-hydroxystearate has the advantages of simple process, , low cost and high yield, can effectively reduce free acid amount in the lithium 12-hydroxystearate finished product, greatly improves the purity of the finished product.

Owner:GANFENG LITHIUM CO LTD

Steel wire rope lubricating grease composition for low-temperature environments

The invention discloses a steel wire rope lubricating grease composition for low-temperature environments. The composition is characterized by containing the following ingredients in parts by weight: 3.2-5.2 parts of 12-OH lithium stearate soap, 0.8-1.3 parts of lithium stearate soap, 54-76 parts of mineral base oil, 15-35 parts of poly-alpha-olefin synthetic oil and 1.0-3.5 parts of colloidal graphite. According to the composition, poly-alpha-olefin synthetic oil with excellent low-temperature properties is adopted as base oil, and meanwhile, the colloidal graphite serves as a friction reducer, so that novel semi-fluid steel wire rope lubricating grease capable of meeting low-temperature use requirements is obtained finally.

Owner:WUXI WEISHUN METAL PROD

Impact resistant rigid vinyl chloride polymer composition and method of making the same

InactiveUS7659334B2Synthetic resin layered productsLiquid carbonaceous fuelsALUMINUM STEARATESAlpha-olefin

The instant invention is an impact resistant rigid vinyl chloride polymer composition, and method of making the same. The impact resistant rigid vinyl chloride polymer composition, according to instant invention, includes a vinyl chloride polymer, an impact modifier, and a lubricant system. The impact modifier includes a chlorinated olefin polymer, and an ethylene / alpha-olefin copolymer. The lubricant system includes a first component, a second component, and a third component. The first component is a carboxylic acid selected from the group consisting of stearic acid, lauric acid, myristic acid, palmitic acid, blends thereof, and combinations thereof. The second component is a hydrocarbon wax selected from the group consisting of a paraffin wax, polyolefin wax, blends thereof, and combinations thereof. The third component is a metal soap selected from the group consisting of calcium stearate, aluminum stearate, copper stearate, lithium stearate, magnesium stearate, sodium stearate, zinc stearate, blends thereof, and combinations thereof. The process for preparing the impact resistant rigid vinyl chloride polymer composition of the instant invention includes the following steps: (1) providing a vinyl chloride polymer; (2) providing an impact modifier as described above; (3) providing a lubricant system as described above; (4) blending the vinyl chloride polymer, the impact modifier, and the lubricant system thereby forming the impact resistant rigid vinyl chloride polymer composition.

Owner:DOW GLOBAL TECH LLC

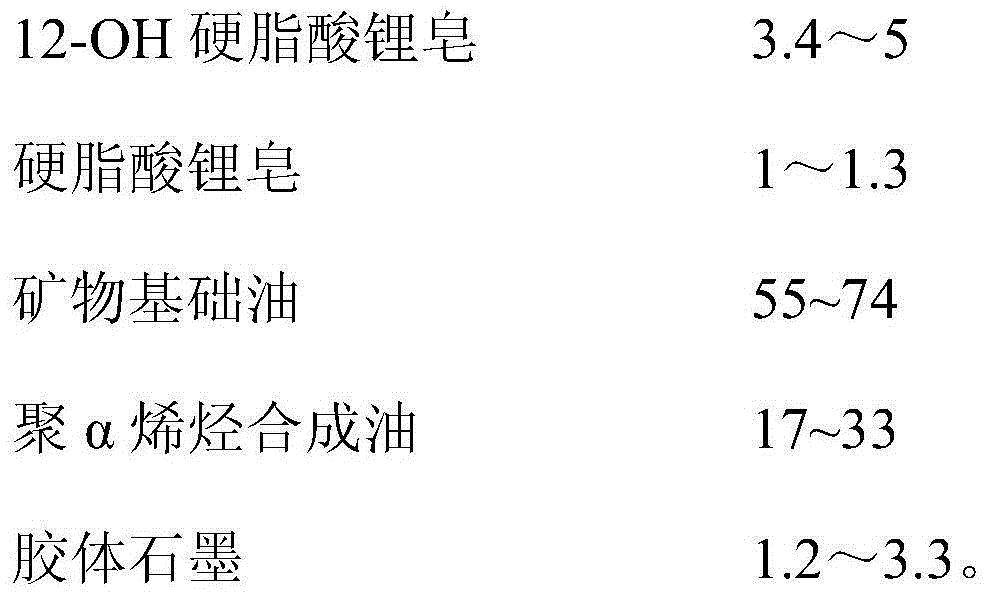

High temperature resisting material for communication optical cable sheath and preparation method of high temperature resisting material

InactiveCN104292646AImprove high temperature resistanceGood physical and mechanical propertiesFibre mechanical structuresAluminum silicateUltra fine

The invention discloses a high temperature resisting material for a communication optical cable sheath and a preparation method of the high temperature resisting material. The high temperature resisting material is prepared from the following raw materials in parts by weight: 50-70 parts of polypropylene, 25-45 parts of polybenzimidazole, 15-20 parts of basic magnesium carbonate hydrate, 3-5 parts of dimethyl-biphenyl diisocyanate, 2-4 parts of N-phenylmaleimide, 16-22 parts of polytetrafluoroethylene, 10-15 parts of silicified graphite, 18-26 parts of terephthalic acid p-phenylenediamine, 10-15 parts of calcium molybdate, 15-20 parts of diisononyl phthalate, 12-18 parts of nanometer titanium phosphate, 10-15 parts of ultra fine aluminum silicate, 4-8 parts of pentaerythritol phosphate, 2-3 parts of lithium stearate, 3-5 parts of calcium acetyl acetone, 4-6 parts of low molecular weight polybutene, 1-2 parts of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate, and 2-3 parts of bisphenol A-bi(diphenyl phosphate). The sheath material provided by the invention has excellent high temperature resisting property, and can still maintain relatively high physics mechanical property after long time working in high temperature environment, and phenomena of softening, decomposition and poor performance cannot occur; meanwhile, the high temperature resisting material has the excellent wearing resistance, corrosion resistance, and aging resistance, so that the comprehensive property of the sheath is greatly improved, and the service life is prolonged.

Owner:安徽电信器材贸易工业有限责任公司

Negative electrode material, preparation method and application thereof

PendingCN114050269AImprove stabilityFast transmissionNegative electrodesSecondary cellsCarbon coatingElectrical battery

The invention relates to the technical field of batteries, in particular to a negative electrode material, a preparation method and application thereof. The negative electrode material is of a core-shell structure, wherein the core-shell structure sequentially comprises an inner core, a middle layer, a first protection layer and a second protection layer from inside to outside, the inner core comprises Si and SiOx, x is more than or equal to 0.5 and less than or equal to 2, the middle layer comprises a lithium silicate compound, the first protection layer comprises a carbon material, and the second protection layer comprises lithium stearate. According to the invention, the negative electrode material can fundamentally solve the problem of precipitation of residual alkali on the surface of a lithium supplement type silica material, the lithium stearate protection layer and the carbon coating layer can play a synergistic role, the lithium ion transmission speed of the material is improved, and the polarization effect is eliminated; and the lithium stearate layer has a long-chain hydrophobic group, so that the material can be further prevented from reacting with H2O, and the material stability is improved.

Owner:BATTERO TECH CORP LTD

Semi-fluid self-cleaning steel rope grease and preparation method thereof

The invention provides semi-fluid self-cleaning steel rope grease which is prepared from the following raw materials: base oil, a thickening agent, a filler, a curing agent, an antioxidant and an oiliness agent, wherein the base oil accounts for 50-70% of total weight; the thickening agent is prepared from the following raw materials in parts by weight: 5-9 parts of microcrystalline wax, 2-4 parts of fumed silica and 5-9 parts of 12-hydroxy lithium stearate soap; the filler is nanometer polytetrafluoroethylene powder and accounts for 8-12 parts by weight; and the curing agent is polyester or liquid ashless dithiophosphate Irgalube-353 and accounts for 6-8 parts by weight. The semi-fluid self-cleaning steel rope grease provided by the invention can float on the surface of a steel rope and can infiltrate into the steel rope, and dust or impurities falling to the steel cable can be washed away by using water.

Owner:XINXIANG HENGXING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com