Premixed bronze powder and preparation method and application thereof

A bronze powder and pre-mixing technology, which is applied in the field of metal alloys, can solve the problems such as the oil content of oil-impregnated bearings that are not mentioned, and achieve the effect of good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

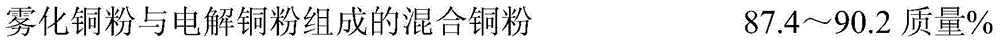

[0034] In this example, premixed bronze powder was prepared from the following raw materials:

[0035]

[0036] The mass percentages of atomized copper powder and electrolytic copper powder in the mixed copper powder are: 90% atomized copper powder and 10% electrolytic copper powder.

[0037] Prepare above-mentioned premixed bronze powder by following method, specifically comprise the following steps:

[0038] (1) In the intermediate frequency melting furnace, the primary copper plate of the raw material is melted into a molten metal, and the high-pressure water with a pressure of 20 MPa injected from a cylindrical high-pressure nozzle with an inner diameter of 5 mm is used to impact the molten metal fluid, dehydrate, dynamically oxidize, and screen , making -350 mesh atomized copper powder;

[0039] (2) Add electrolytic copper powder to the atomized copper powder, mix evenly, carry out high-temperature sintering and agglomeration at 850° C., pulverize, and sieve to obtain...

Embodiment 2

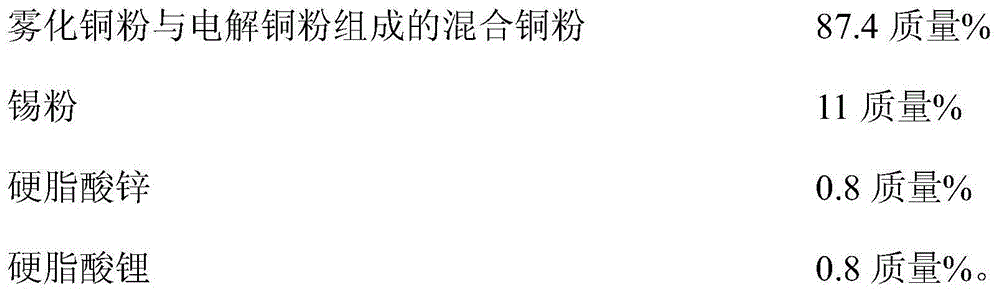

[0042] In this example, premixed bronze powder was prepared from the following raw materials:

[0043]

[0044] The mass percentages of atomized copper powder and electrolytic copper powder in the mixed copper powder are: 80% atomized copper powder and 20% electrolytic copper powder.

[0045] Prepare above-mentioned premixed bronze powder by following method, specifically comprise the following steps:

[0046] (1) In the intermediate frequency melting furnace, the primary copper plate of the raw material is melted into a molten metal, and the high-pressure water with a pressure of 22 MPa injected from a cylindrical high-pressure nozzle with an inner diameter of 5 mm is used to impact the molten metal fluid, dehydrate, dynamically oxidize, and sieve , making -350 mesh atomized copper powder;

[0047] (2) Add electrolytic copper powder to the atomized copper powder, mix evenly, carry out high-temperature sintering and agglomeration at 800° C., pulverize, and sieve to obtain ...

Embodiment 3

[0050] In this example, premixed bronze powder was prepared from the following raw materials:

[0051]

[0052] The mass percentages of atomized copper powder and electrolytic copper powder in the mixed copper powder are: 95% atomized copper powder and 5% electrolytic copper powder.

[0053] Prepare above-mentioned premixed bronze powder by following method, specifically comprise the following steps:

[0054] (1) In the intermediate frequency melting furnace, the primary copper plate of the raw material is melted into a molten metal, and the high-pressure water with a pressure of 25 MPa injected from a cylindrical high-pressure nozzle with an inner diameter of 5 mm is used to impact the molten metal fluid, dehydrate, dynamically oxidize, and sieve , making -350 mesh atomized copper powder;

[0055] (2) Add electrolytic copper powder to the atomized copper powder, mix evenly, carry out high-temperature sintering and agglomeration at 900° C., pulverize, and sieve to obtain m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com