Ultralow-temperature bearing lubricating grease composition and preparation method thereof

A bearing lubrication and composition technology, applied in the field of ultra-low temperature bearing grease composition and preparation, can solve the problems of damage to parts such as machinery and motors, large changes in grease viscosity, affecting the normal use of equipment, etc., achieving long service life, excellent low temperature and other problems. Flow properties, the effect of shortening the saponification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

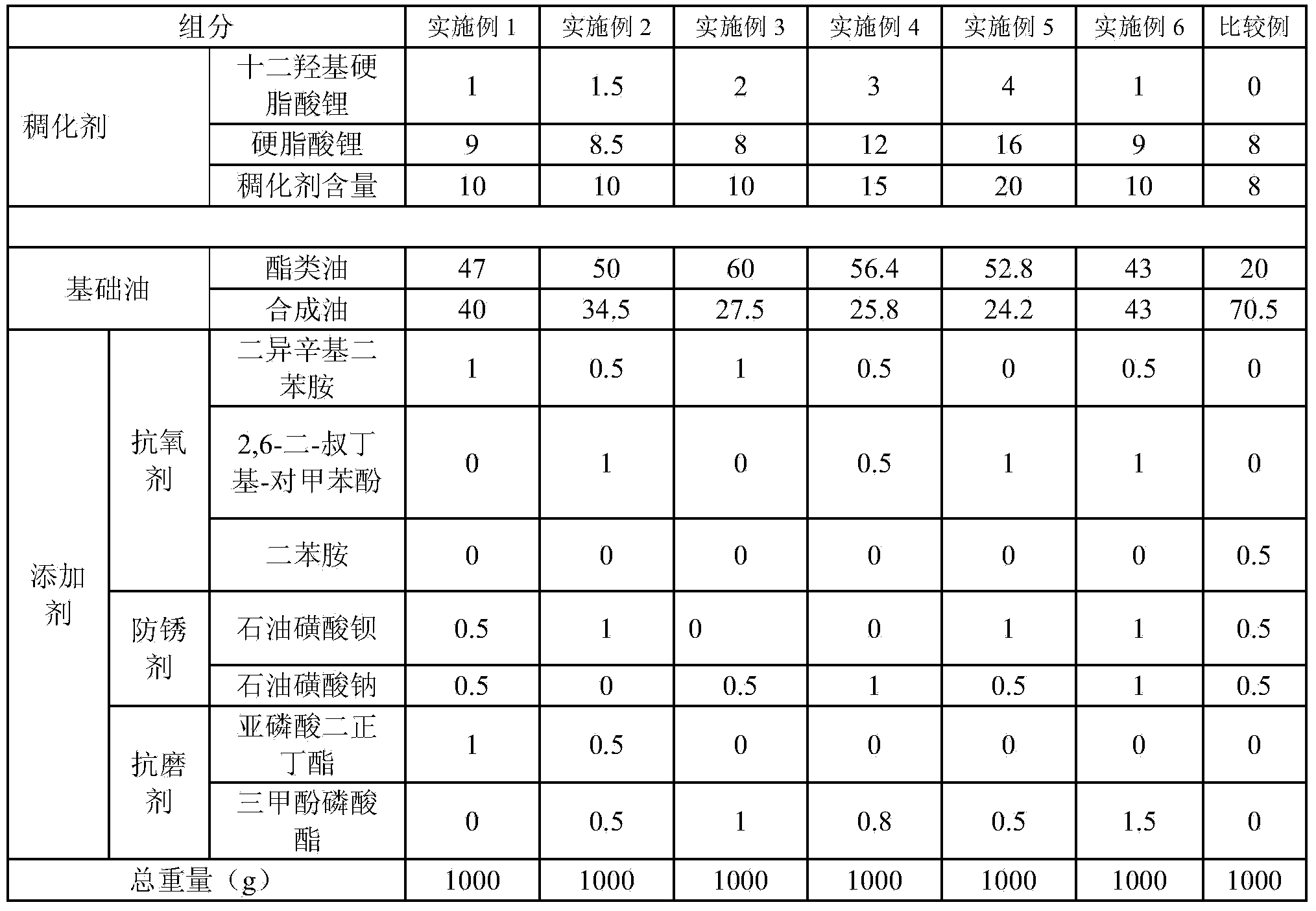

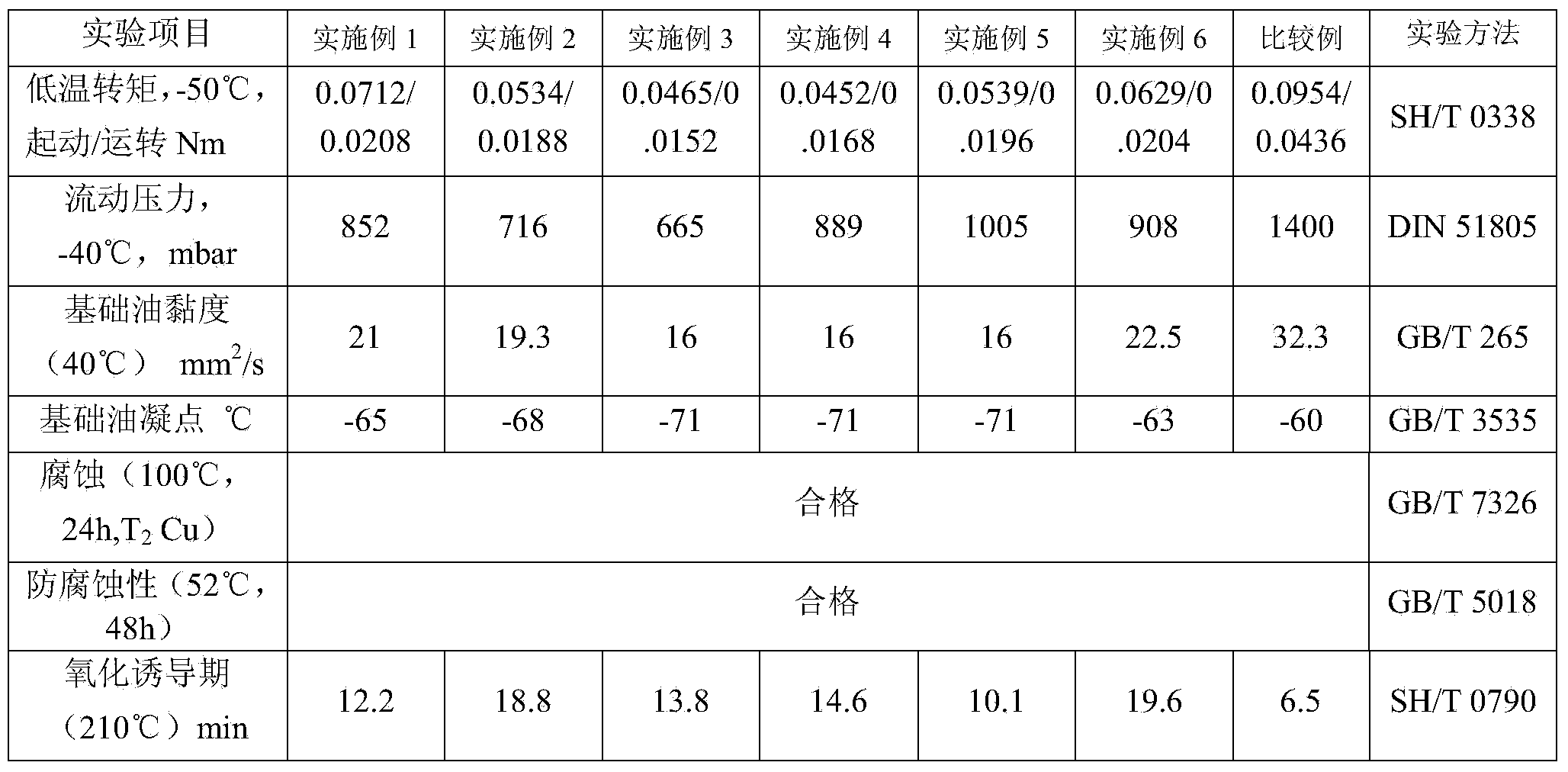

Embodiment 1

[0027] Example 1 Add 90g of stearic acid in the thickener to 400g of autoclave oil. The autoclave oil is a synthetic oil. Add 14.5g of lithium hydroxide, raise the temperature to 90°C, and then add 10g of dodecahydroxy stearic acid after the reaction is completed. Fatty acids react. After the drainage is completed, add 70g of ester oil to the reaction kettle, stir and heat to 185-205°C, add the remaining 400g of ester oil to cool, add 10g of antioxidant dioctyl diphenylamine, continue to stir, and cool down naturally After reaching 70-80°C, add 5g of barium petroleum sulfonate, 5g of sodium petroleum sulfonate, anti-rust agent, and 10g of di-n-butyl phosphite as an anti-wear agent, stir evenly, and after post-processing, check the noise level, the finished tank Pack.

Embodiment 2

[0028] Example 2 Add 85g of stearic acid in the thickener to 345g of autoclave oil. The autoclave oil is synthetic oil. Add 15.7g of lithium hydroxide, raise the temperature to 90°C, and then add 15g of dodecahydroxy stearic acid after the reaction is completed. Fatty acids react. After the drainage is completed, add 100g of ester oil to the reaction kettle, stir and heat to 185-205°C, add the remaining 400g of ester oil to cool, add 10g of antioxidant dioctyl diphenylamine, continue to stir, and cool down naturally After reaching 70-80°C, add 10g of barium petroleum sulfonate as an anti-rust agent, 5g of di-n-butyl phosphite and 5g of tricresyl phosphate as anti-wear agents, stir evenly, and perform post-treatment to detect the noise level. The finished tank Pack.

Embodiment 3

[0029] Example 3 Add 80g of stearic acid in the thickener to 275g of autoclave oil. The autoclave oil is synthetic oil. Add 15.7g of lithium hydroxide, raise the temperature to 90°C, and then add 20g of dodecahydroxy stearic acid after the reaction is completed. Fatty acids react. After the drainage is completed, add 200g of ester oil to the reaction kettle, stir and heat to 185-205°C, add the remaining 400g of ester oil to cool, add 5g of diisooctyl diphenylamine, 10g of 2,6-di- After tert-butyl-p-cresol, continue to stir, and after naturally cooling down to 70-80°C, add 5g of sodium petroleum sulfonate as a rust inhibitor, and 10g of tricresyl phosphate as an anti-wear agent, stir evenly, and perform post-treatment, The noise level is detected and the finished product canned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com