Patents

Literature

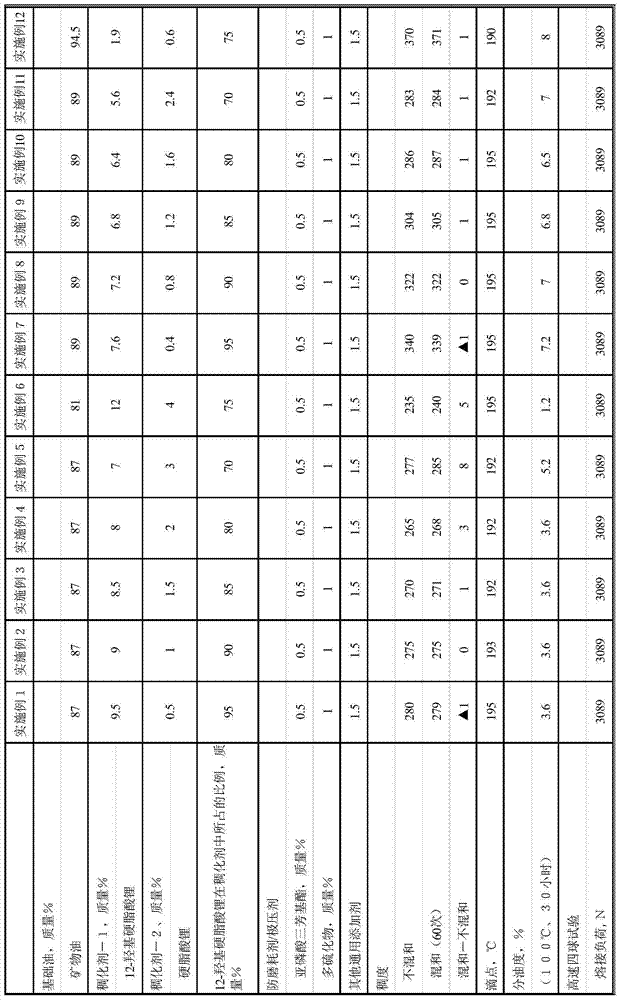

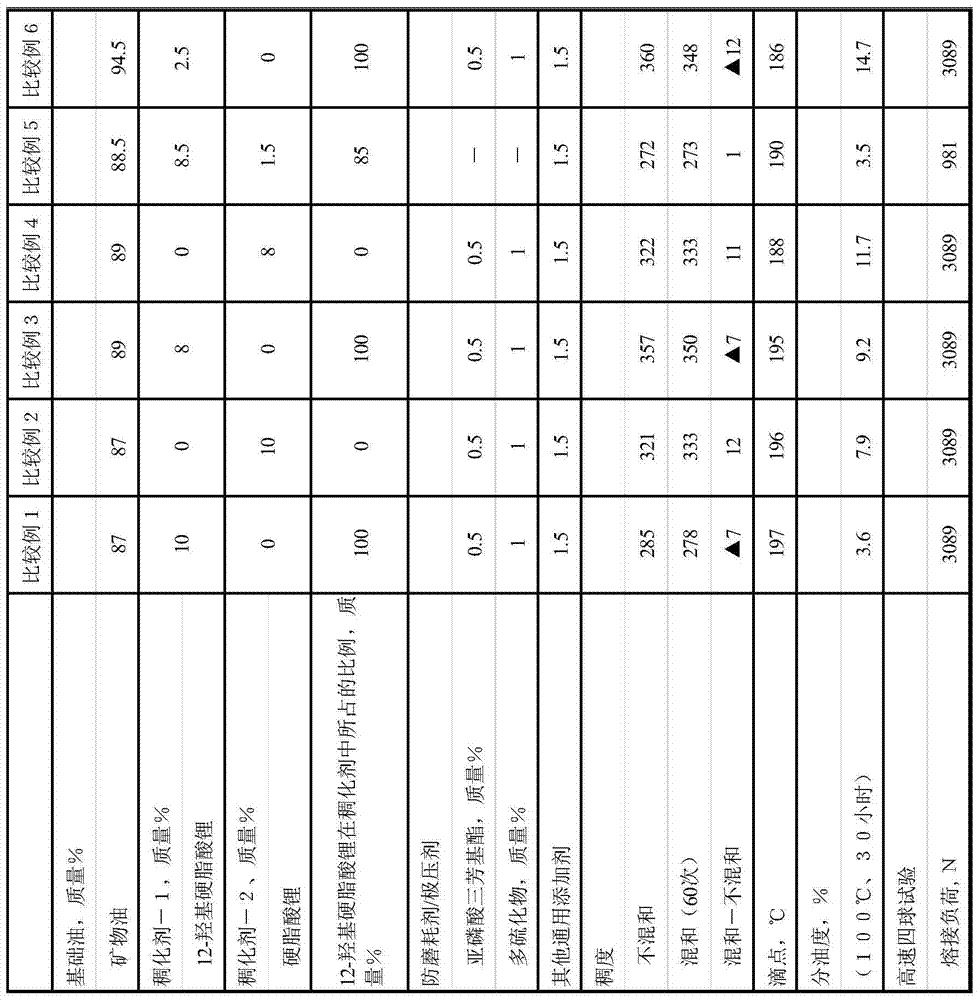

34 results about "Lithium 12-hydroxystearate" patented technology

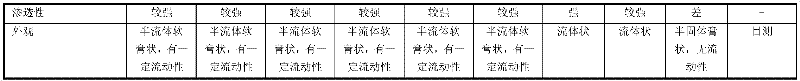

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

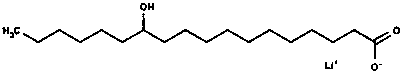

Lithium 12-hydroxystearate is a chemical compound classified as a lithium soap. In chemistry, "soap" refers to salts of fatty acids. Lithium 12-hydroxystearate is a white solid. Lithium soaps are key component of many lubricating greases.

Bearing lubricating grease and preparation method thereof

ActiveCN102977978AHigh dropping point temperatureNot collapseLubricant compositionLithium hydroxideAntioxidant

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

Special lubricating grease composition for steel wire rope

ActiveCN102250670AImprove water resistanceImprove the protective effectLubricant compositionMicrocrystalline waxLithium 12-hydroxystearate

The invention relates to a special lubricating grease composition for a steel wire rope. The composition comprises the following components in percentage by weight: 2.0-5.2% of lithium 12-hydroxystearate soap, 0.5-1.3% of lithium stearate soap, 53.5-76% of mineral base oil, 15.0-40.0% of extract oil, 1.3-6.3% of microcrystalline wax and 0.2-1.2% of diphenylamine. The lubricating grease provided by the invention has the characteristics that blended base oil containing high-viscosity extract oil is utilized to prepare specific-thickness semi-fluid lubricating grease for the steel wire rope, theadhesion and infiltration capability of the product are improved, and the problems of oil splashing, loss, atmospheric environment pollution and the like of the existing product are solved; and a microcrystalline wax additive is used for improving the water resistance and protective properties of the lubricating grease for the steel wire rope. The lubricating grease provided by the invention has dropping point larger than 165 DEG C, is free of volatile solvent, is convenient for coating, has low production cost and enhanced lubrication effects, and can effectively meet the internal and external lubrication and protection requirements of the steel wire rope during operation.

Owner:CHINA PETROLEUM & CHEM CORP

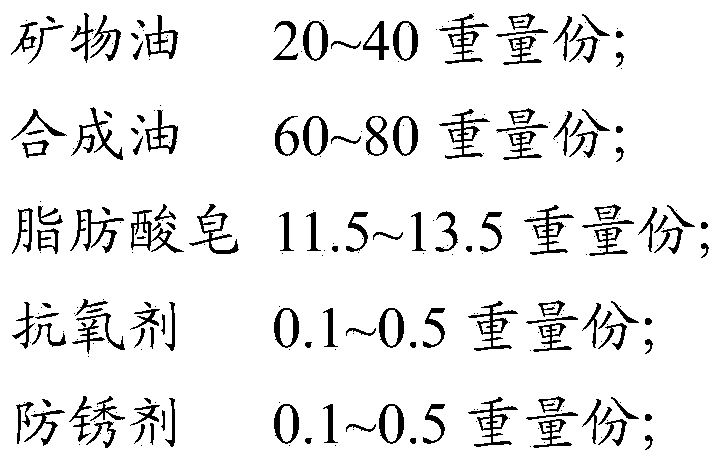

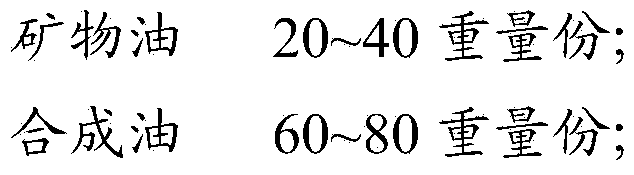

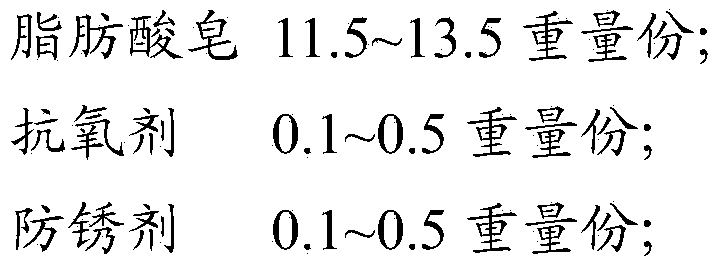

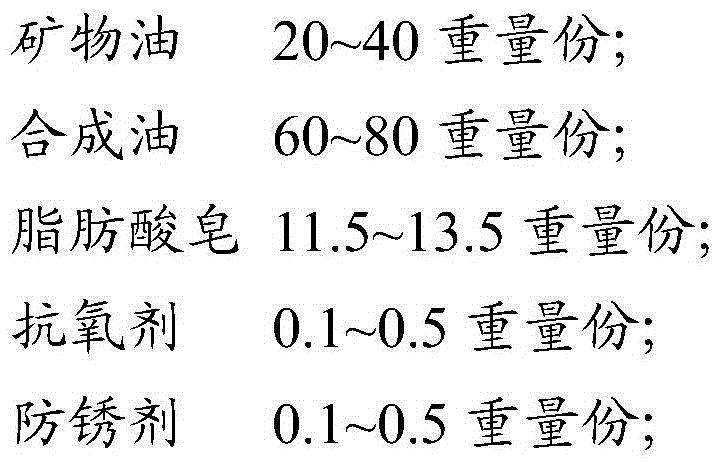

Low-temperature lubricating grease and preparation method thereof

ActiveCN103525510AHigh viscosity indexImprove viscosity indexLubricant compositionAntioxidantEvaporation

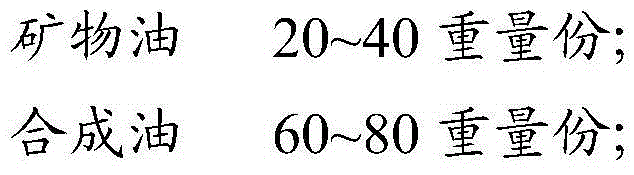

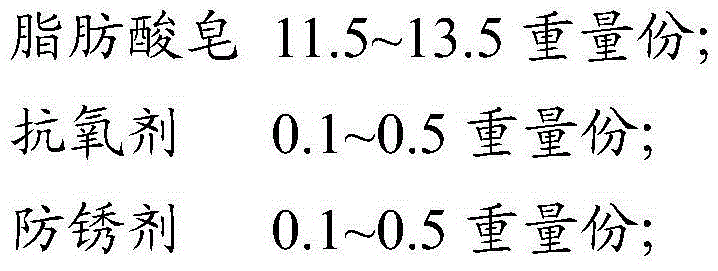

The invention provides low-temperature lubricating grease and a preparation method thereof. The low-temperature lubricating grease comprises mineral oil, synthesized oil, fatty acid soap, an antioxidant and an antirust agent. Compared with the prior art, the low-temperature lubricating grease is characterized in that semi-synthesized oil obtained by mixing III-type oil and ester oil and / or PAO (poly alpha olefin) oil is used as basic oil; the III-type oil has a high viscosity index and is high in high-temperature and low-temperature performance, oxidation stability, heat stability and evaporation performance; the ester oil and the PAO oil also have high viscosity indexes and are high in low-temperature performance; moreover, a mixture of lithium stearate and 12-hydroxy lithium stearate is used as a thickening agent for thickening the semi-synthesized oil, so that the low-temperature lubricating grease is high in low-temperature performance, and a used component can be normally lubricated under low temperature; the applicable temperature range is large; furthermore, the thickening agent is easy to synthesize.

Owner:CHINA PETROLEUM & CHEM CORP

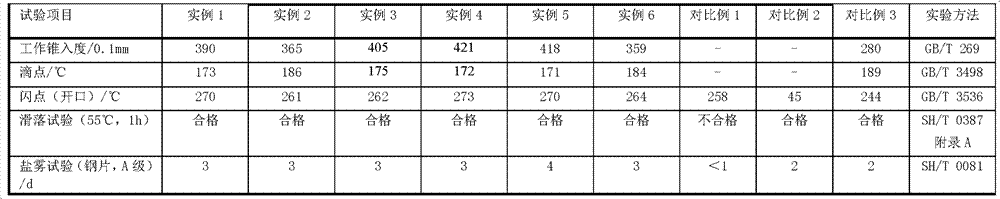

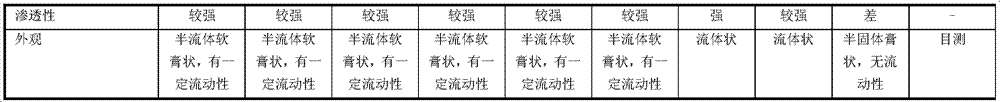

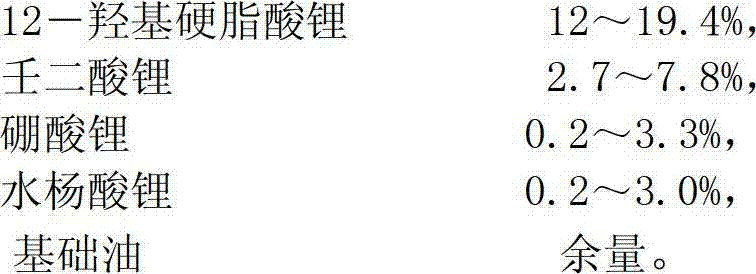

Composition of four-component lithium complex grease and preparation method thereof

The invention belongs to a composition of four-component lithium complex grease and a preparation method thereof. 12-lithium hydroxyl stearate, lithium azelaic acid or lithium sebacic acid, lithium boric acid and lithium salicylate are added into base oil. Four-component complex lithium prepared by controlling complex saponification temperature and time in a first step, alkali adding temperature in a second step, complex co-crystallization temperature and time and the highest temperature by a two-step saponification process has the advantages of high adhesion property, excellent high temperature leakage resistance, long high-temperature bearing service life, high comprehensive performance and capability of meeting the requirement of the lubricating of high-temperature environment equipment and high-temperature centralized pumping and lubricating. The lithium complex grease of the invention belongs to high-temperature grease of which the dropping point is not less than 260 DEG C and which has the prominent advantages of high adhesion property, excellent high temperature leakage resistance and long high-temperature bearing service life at the temperature of 160 DEG C. Compared with polyurea grease, the lithium complex grease cannot be hardened at a high temperature; and compared with the ordinary two-component or three-component complex lithium, the lithium complex grease has the advantages of high adhesion property, excellent high temperature leakage resistance and long high-temperature bearing service life.

Owner:CHINA PETROLEUM & CHEM CORP

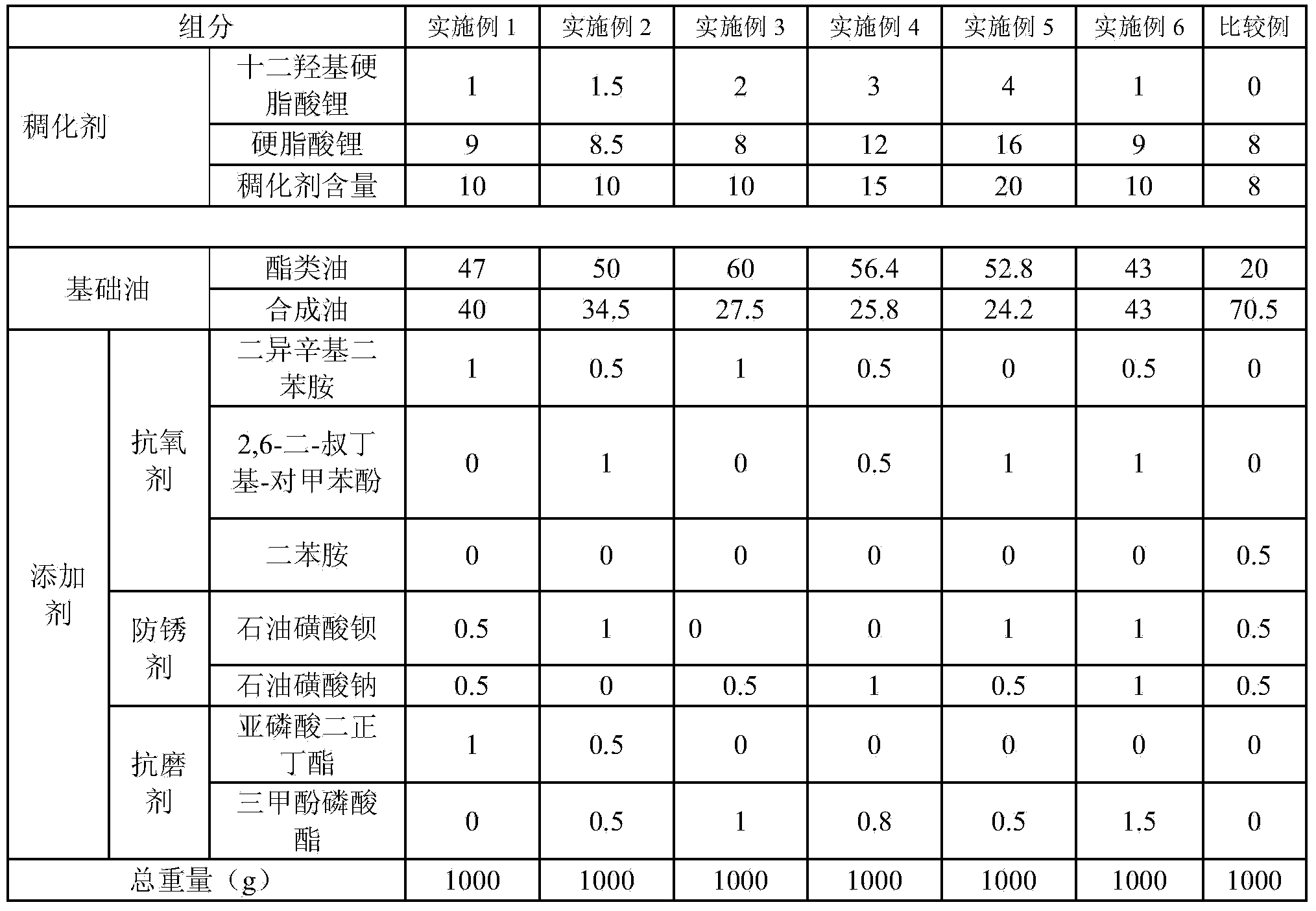

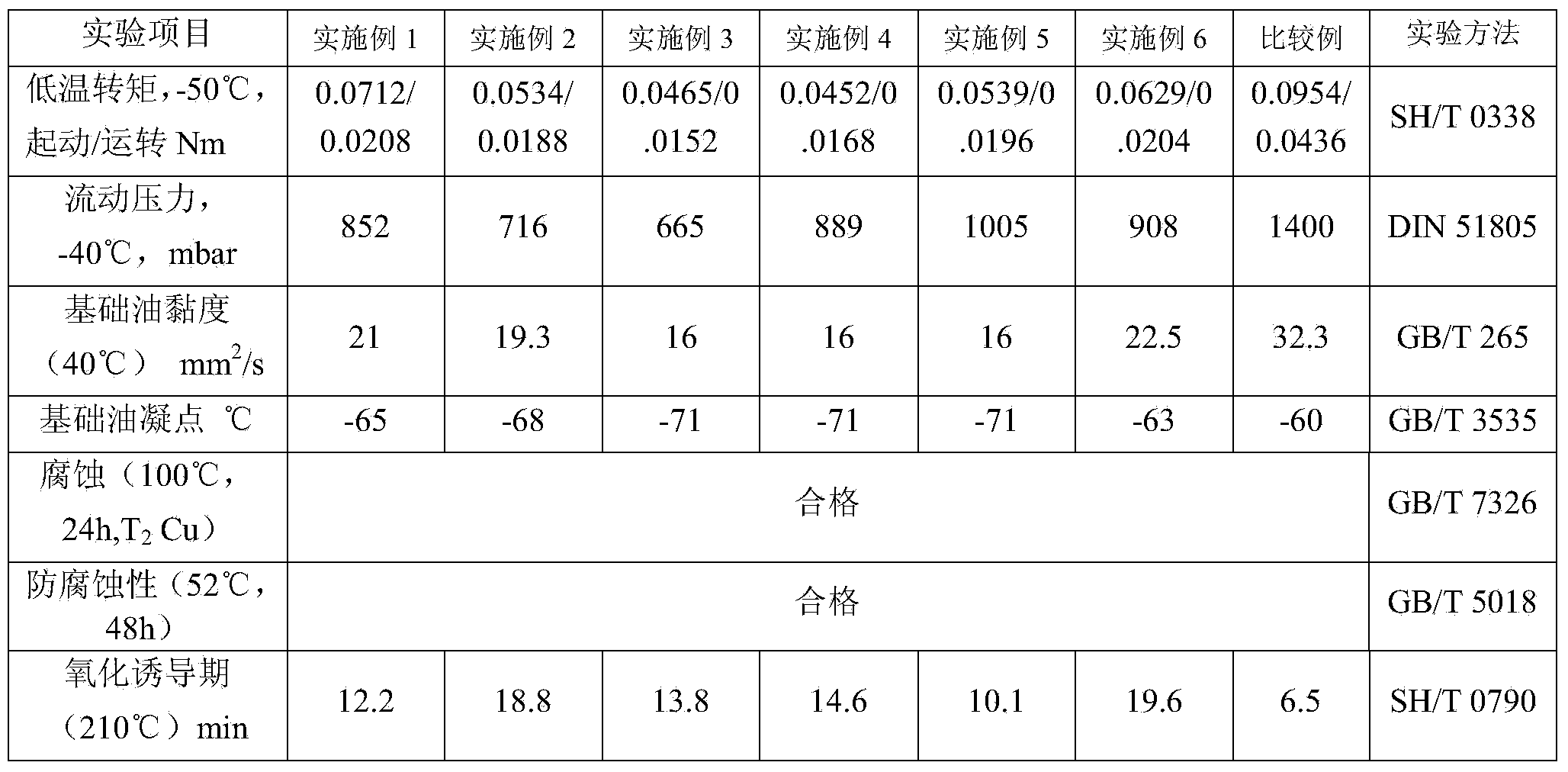

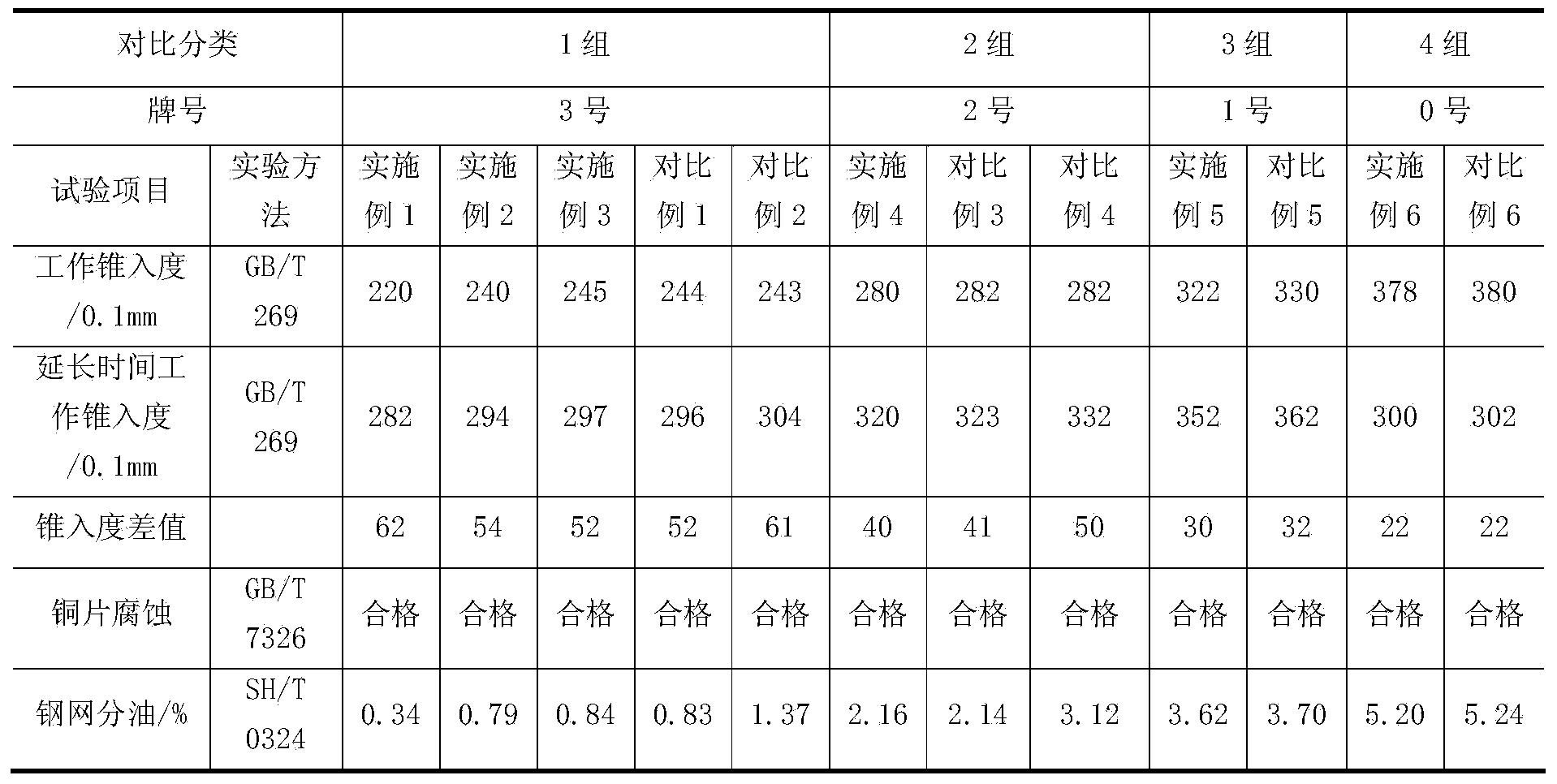

Ultralow-temperature bearing lubricating grease composition and preparation method thereof

InactiveCN104164287AImprove Oxidation StabilityGood starting/running torqueLubricant compositionAfter treatmentAntioxidant

The invention relates to an ultralow-temperature bearing lubricating grease composition and a preparation method thereof. The ultralow-temperature bearing lubricating grease composition comprises 10-20% of a thickener namely lithium 12-hydroxystearate-lithium stearate complex soap, 75-85% of base oil, 0.5-4.0% of an additive (a) namely arylamine and / or phenol antioxidant, 0.5-1.5% of an additive (b) namely a sulfonate rust inhibitor and 0.5-2% of an additive (c) namely a phosphorus antiwear additive. The ultralow-temperature bearing lubricating grease composition comprises the following steps: adding stearic acid into the thickener to react, and adding 12-hydroxystearic acid to react; and adding 1 / 2-2 / 3 of base oil into a reaction kettle, heating to 185-205 DEG C while stirring, adding the rest of base oil, cooling, adding the antioxidant, continuously stirring, naturally cooling to 70-80 DEG C, adding the rust inhibitor and antiwear additive, stirring uniformly, carrying out after-treatment, and canning the finished product. The lubricating grease has favorable oxidation stability; and the lubricating grease has ultralow starting / operating torque, and can ensure the long service life of the lubricating grease and bearing at the ultralow temperature of -60 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Lithium-based lubricating grease composition and preparation method for same

InactiveCN103525503AImprove structural stabilityIncrease frictionBase-materialsLithium 12-hydroxystearateLithium stearate

The invention provides a lithium-based lubricating grease composition and a preparation method for the lithium-based lubricating grease composition. The lithium-based lubricating grease is prepared by saponifying special high-acid value mineral base oil. The preparation method comprises the following steps of putting the high-acid value mineral base oil into a kettle, adding 12-lithium hydroxyl-stearate soap and lithium stearate soap, and performing stirring and heating; when temperature rises to 210 to 220 DEG C, keeping the temperature, and performing stirring for 1 to 5 minutes; putting ordinary mineral base oil into the kettle, quickly cooling the materials, and adding an additive when the temperature reaches 140 to 150 DEG C; uniformly stirring the materials, and discharging the materials from the kettle; grinding the materials to obtain a finished product by using a three-roller grinding machine. According to the lubricating grease composition, conventional base oil resources in China are reasonably utilized instead of a naphthenic acid raw material, so that the production cost of the lubricating grease is remarkably lowered; the lubricating grease has high mechanical stability, colloid stability and lubricating performance, and the friction and abrasion conditions of mechanical equipment during operation can also be effectively improved; the produced lubricating grease can be used for lubricating automobiles, construction machinery and other mechanical equipment.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil for motor and preparation method thereof

InactiveCN104830440APlay a role in lubrication protectionWill not corrodeAdditivesPolyethylene oxideAntioxidant

The invention discloses a lubricating oil for motor and a preparation method thereof. The lubricating oil comprises a base oil, an antioxidant, heptadecenyl imidazoline alkenyl succinic acid salt, tricresyl phosphate, polyethyl acrylate, methyl silicone oil, polyethylene oxide, and lithium 12-hydroxystearate, wherein the polyethylene oxide has a weight average molecular weight of 1000-3000, and the polyethyl acrylate has weight average molecular weight of 2000-4000. The lubricating oil has excellent viscosity, kinematic viscosity index and pH value of 6-8l; while the preparation method of the lubricating oil is simple; and the raw materials are easily available.

Owner:ANHUI YUANFENG PIPELINE TECH CO LTD

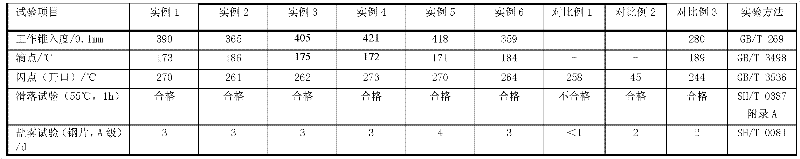

Preparation method of lithium 12-hydroxystearate

InactiveCN107840788AReduce free acidHigh purityOrganic compound preparationCarboxylic acid salt preparationEmulsionLithium 12-hydroxystearate

The invention discloses a preparation method of lithium 12-hydroxystearate. The method comprises the following steps: A. mixing 12-hydroxystearic acid with water, then heating up to 90-100 DEG C, andmaintaining the constant temperature for 40-60min to obtain a 12-hydroxystearic acid solution; B. mixing lithium hydroxide monohydrate with water to prepare a lithium hydroxide solution with a concentration of 2.5-10%, heating up to 80-90 DEG C, and maintaining the constant temperature for 15-30min; C. adding the lithium hydroxide solution into the 12-hydroxystearic acid solution, maintaining thetemperature to be 90 DEG C or above, carrying out a neutral reaction, and stirring for carrying out a reaction for 40-60min; D. after the reaction is finished, carrying out an emulsion reaction for 15-30min; E. after emulsification is finished, carrying out centrifugal dewatering, and carrying out elution on the product with hot water at the temperature of 90 DEG C or above until the pH value of the washing liquid is 8-9 so as to obtain a lithium 12-hydroxystearate wet material; F. drying the lithium 12-hydroxystearate wet material to obtain a dry material; G. crushing the dry material to obtain the finished product. The preparation method of the lithium 12-hydroxystearate has the advantages of simple process, , low cost and high yield, can effectively reduce free acid amount in the lithium 12-hydroxystearate finished product, greatly improves the purity of the finished product.

Owner:GANFENG LITHIUM CO LTD

Motor lubricating oil and preparation method thereof

InactiveCN104789307APlay a role in lubrication protectionWill not corrodeAdditivesSulfonatePolyethylene oxide

The invention discloses motor lubricating oil and a preparation method thereof. The motor lubricating oil is prepared from base oil, an anti-oxidant, dinonylnaphthalenesulfonic acid barium salt, trioctyl trimellitate, sodium alkyl naphthalene sulfonate, methyl silicone oil, polyethylene oxide and lithium 12-hydroxystearate, wherein the weight-average molecular weights of polyethylene oxide and sodium alkyl naphthalene sulfonate are 1000-3000 and 2000-4000 respectively. The motor lubricating oil is high in viscosity and kinematic viscosity index, and has a pH value of 6-8; the preparation method of the motor lubricating oil is simple, and raw materials are easy to obtain.

Owner:ANHUI YUANFENG PIPELINE TECH CO LTD

Warm Molding Raw Material Powder and Warm Molding Method

InactiveUS20080056929A1High lubricatingHigh pressing propertyTransportation and packagingMetal-working apparatusMetallurgyLithium 12-hydroxystearate

A hydroxy fatty acid salt having an average particle diameter of from 5 μm to 100 μm with a composition of from 0.3 wt % to 2 wt %, and more preferably, from 0.5 wt % to 2 wt % is added to a raw material powder in powder metallurgy, and worm molding is performed. In addition, a hydroxy fatty acid salt having an average particle diameter of 50 μm or less is attached on a mold in advance, and after that, the warm molding is performed. As a hydroxy fatty acid salt, 12-hydroxy lithium stearate is suitably used.

Owner:DIAMET CORP

Anticorrosion and antirust reinforced concrete, and microcirculation construction production method thereof

InactiveCN106517932AImprove impermeabilityImprove stress resistanceCalcium silicatePolyvinyl alcohol

The invention relates to an anticorrosion and antirust reinforced concrete, and a microcirculation construction production method thereof, and belongs to the field of building concrete materials. The anticorrosion and antirust reinforced concrete for promoting the structure microcirculation and refinement of a concrete aggregate compound and enhancing the interface combination and the density comprises, by weight, 160 parts of Portland cement, 90 parts of broken stones, 60 parts of fine sands, 30 parts of calcium chloride, 12 parts of magnesium silicate, 10 parts of active calcium silicate, 8 parts of sorbose calcium, 9 parts of dialuminum hydrogen phosphate, 6 parts of strontium oxide, 8 parts of brucite powder, 18 parts of fly ash, 4 parts of white clay powder, 12 parts of silica micro-powder, 6 parts of polyvinyl alcohol, 15 parts of phosphogypsum, 5 parts of lithium 12-hydroxystearate, 6 parts of potassium tripolyphosphate, 5 parts of sodium allyl sulfonate, 2 parts of a water reducer, 2 parts of an expanding agent, 15 parts of barium hydroxide and a proper amount of water. The anticorrosion and antirust reinforced concrete has excellent impact, compression, tensile, crack, corrosion and rust resistance.

Owner:浙江长兴恒基科技有限公司

Special lubricating grease composition for steel wire rope

ActiveCN102250670BImprove water resistanceImprove the protective effectLubricant compositionMicrocrystalline waxLithium stearate

The invention relates to a special lubricating grease composition for a steel wire rope. The composition comprises the following components in percentage by weight: 2.0-5.2% of lithium 12-hydroxystearate soap, 0.5-1.3% of lithium stearate soap, 53.5-76% of mineral base oil, 15.0-40.0% of extract oil, 1.3-6.3% of microcrystalline wax and 0.2-1.2% of diphenylamine. The lubricating grease provided by the invention has the characteristics that blended base oil containing high-viscosity extract oil is utilized to prepare specific-thickness semi-fluid lubricating grease for the steel wire rope, theadhesion and infiltration capability of the product are improved, and the problems of oil splashing, loss, atmospheric environment pollution and the like of the existing product are solved; and a microcrystalline wax additive is used for improving the water resistance and protective properties of the lubricating grease for the steel wire rope. The lubricating grease provided by the invention has dropping point larger than 165 DEG C, is free of volatile solvent, is convenient for coating, has low production cost and enhanced lubrication effects, and can effectively meet the internal and external lubrication and protection requirements of the steel wire rope during operation.

Owner:CHINA PETROLEUM & CHEM CORP

Composition of four-component lithium complex grease and preparation method thereof

The invention belongs to a composition of four-component lithium complex grease and a preparation method thereof. 12-lithium hydroxyl stearate, lithium azelaic acid or lithium sebacic acid, lithium boric acid and lithium salicylate are added into base oil. Four-component complex lithium prepared by controlling complex saponification temperature and time in a first step, alkali adding temperature in a second step, complex co-crystallization temperature and time and the highest temperature by a two-step saponification process has the advantages of high adhesion property, excellent high temperature leakage resistance, long high-temperature bearing service life, high comprehensive performance and capability of meeting the requirement of the lubricating of high-temperature environment equipment and high-temperature centralized pumping and lubricating. The lithium complex grease of the invention belongs to high-temperature grease of which the dropping point is not less than 260 DEG C and which has the prominent advantages of high adhesion property, excellent high temperature leakage resistance and long high-temperature bearing service life at the temperature of 160 DEG C. Compared with polyurea grease, the lithium complex grease cannot be hardened at a high temperature; and compared with the ordinary two-component or three-component complex lithium, the lithium complex grease has the advantages of high adhesion property, excellent high temperature leakage resistance and long high-temperature bearing service life.

Owner:CHINA PETROLEUM & CHEM CORP

Oxidization-resisting engine lubricating oil and preparation method thereof

InactiveCN106675723AEasy to cleanExtended service lifeLubricant compositionPolyethylene oxideHydroxystearic Acid

The invention discloses oxidization-resisting engine lubricating oil. The lubricating oil is prepared from the following components in parts by mass: 51 to 56 parts of base oil, 13 to 16 parts of polyethylene oxide, 5 to 7 parts of nano silicon dioxide, 5 to 9 parts of tricresyl phosphate, 3 to 5 parts of alkyl diphenylamine, 1 to 3 parts of lithium 12-hydroxystearate, 3 to 5 parts of a viscosity index improver OCP (Olefin Co-Polymer), 2 to 5 parts of polymethacrylate, 2 to 4 parts of dialkyl dithiophosphate, 2 to 5 parts of octylphenol, 4 to 7 parts of a sulfonate detergent, 2 to 6 parts of dibutyl phosphite, 1 to 3 parts of dimethyl silicone oil, 1 to 3 parts of polyisobutylene butane diacid pentaerythritol ester and 1 to 3 parts of an anti-foaming agent T901. The oxidization-resisting engine lubricating oil disclosed by the invention is high-performance engine lubricating oil which is designed by adopting a special researched new-technology formula aiming at characteristics that a high-load diesel engine is operated for a long period, a working condition is complicated, a heat load is heavy, diesel oil of different regions is frequently replaced and the like. The oxidization-resisting engine lubricating oil has transcendental high-temperature detergency and dispersion performance; piston ring sticking and cylinder sleeve polishing, caused by a fuel straight injection technology, are effectively prevented and an engine is cleaned greatly.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Formula and production process of lithium-based lubricating grease

InactiveCN104560287AAnti-rustThe formula is scientific and reasonableLubricant compositionLithium hydroxideLithium 12-hydroxystearate

The invention provides a formula and a production process of lithium-based lubricating grease and relates to the technical field of lubricating grease. The production process comprises the steps of adequately mixing 1 / 3 of base oil with hydrogenated castor oil, lithium 12-hydroxystearate soap and lithium hydroxide soap, saponifying the mixture with equivalent lithium hydroxide to basically form a soap-oil sol state, adding 1 / 3 of base oil, further heating to the highest refining temperature so that the a soap-oil system in a grease preparation kettle is in a complete true solution state, cooling a drum cooler from a phase inversion temperature to 38-65 DEG C within several seconds by taking the rest 1 / 3 of base oil as snap-chilling mixed oil, and carrying out grinding, homogenization and degasification so as to obtain the lithium-based lubricating grease. The formula is scientific and reasonable; furthermore, by virtue of the scientific and simple production process, the degasification conversion rate can reach above 99.5%; and the produced products are all superior to general lithium-based lubricating grease products.

Owner:WUXI FEITIAN GREASE

A kind of low-temperature lubricating grease and preparation method thereof

ActiveCN103525510BHigh viscosity indexImprove viscosity indexLubricant compositionAntioxidantEvaporation

The invention provides low-temperature lubricating grease and a preparation method thereof. The low-temperature lubricating grease comprises mineral oil, synthesized oil, fatty acid soap, an antioxidant and an antirust agent. Compared with the prior art, the low-temperature lubricating grease is characterized in that semi-synthesized oil obtained by mixing III-type oil and ester oil and / or PAO (poly alpha olefin) oil is used as basic oil; the III-type oil has a high viscosity index and is high in high-temperature and low-temperature performance, oxidation stability, heat stability and evaporation performance; the ester oil and the PAO oil also have high viscosity indexes and are high in low-temperature performance; moreover, a mixture of lithium stearate and 12-hydroxy lithium stearate is used as a thickening agent for thickening the semi-synthesized oil, so that the low-temperature lubricating grease is high in low-temperature performance, and a used component can be normally lubricated under low temperature; the applicable temperature range is large; furthermore, the thickening agent is easy to synthesize.

Owner:CHINA PETROLEUM & CHEM CORP

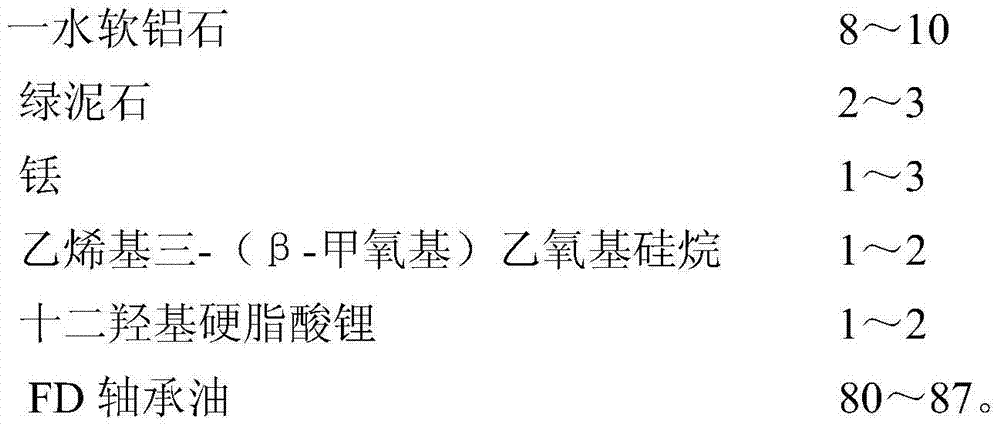

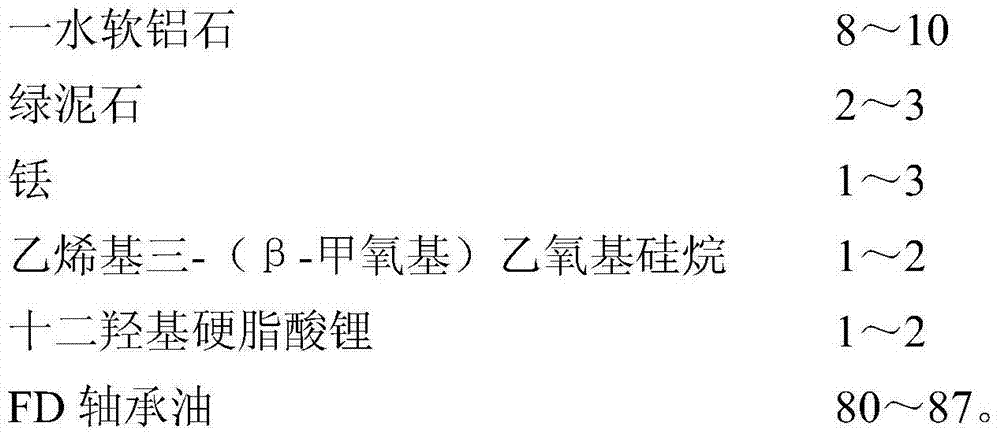

FD bearing oil composition, preparation method and applications thereof

The invention discloses an FD bearing oil composition and a preparation method and applications thereof. The composition is composed of the following components in parts by weight: 6-8 parts of boehmite, 3-5 parts of chlorite, 1-3 parts of thulium, 1-2 parts of vinyl tri(beta-methoxy) triethoxy methylsilane, 1-2 parts of lithium 12-hydroxystearate and 80-87 parts of FD bearing oil. The prepared FD bearing oil composition can be formed into metal ceramic wearing layers with high intensity on the working surfaces of inner and outer rings of a bearing and the surface of a rolling element, so that the bearing is kept to move smoothly, the failure rate is reduced, the service life of the bearing is prolonged by more than five times, the consumption of lubricating material is saved, and the effect of environmental protection is achieved. The product raw material are easily available, the product is scientific in formula, simple in manufacture process, low in cost and good in performance. The FD bearing oil composition is used as high-speed spindle oil and sewing-machine oil in textile industry, and particularly applicable to lubricating spindle bearings of precision machine tools of which the operating temperature is more than 0 DEG C, and other high-speed sliding bearings lubricated by cycling, oil bath and oil fog, or precision rolling bearings.

Owner:DALIAN MARITIME UNIVERSITY

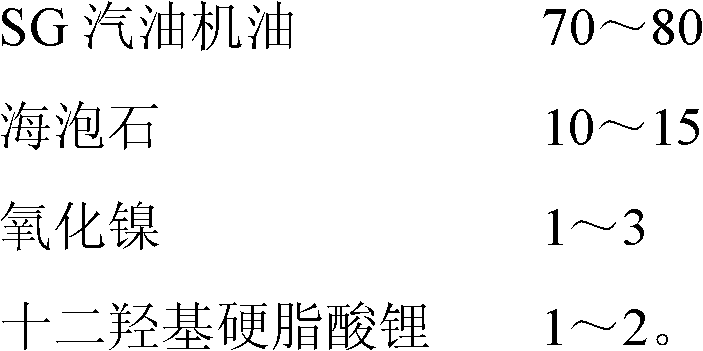

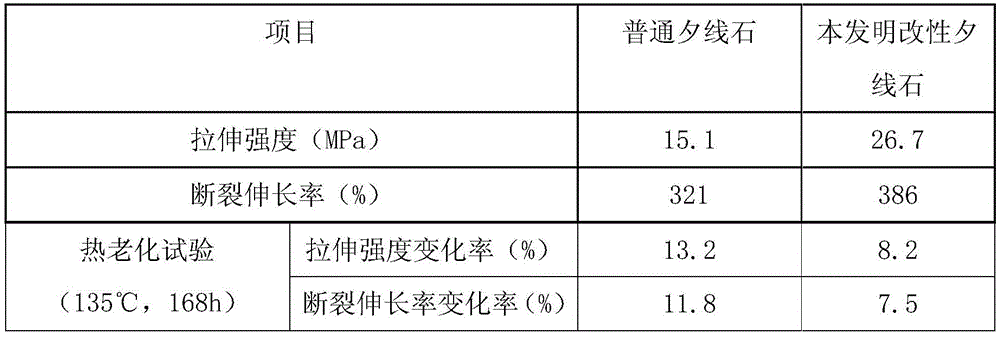

SG gasoline-engine oil composition, and preparation method and application thereof

The invention relates to an SG gasoline-engine oil composition, and a preparation method and application thereof, belonging to the technical field of materials. The SG gasoline-engine oil composition is prepared from the following components in parts by mass: 70-80 parts of SG gasoline-engine oil, 10-15 parts of meerschaum, 1-3 parts of nickel oxide and 1-2 parts of lithium 12-hydroxystearate. The SG gasoline-engine oil composition solves the problem that black oil sludge can be easily generated in the engine cylinder under the repeatedly alternate traveling conditions of high-temperature high speed and low-temperature low speed, and can quickly form a superhard anti-wear layer in the engine cylinder and on the piston ring, thereby keeping the effective power of the engine and reducing the emission of PM2.5 particulate matters in tail gas. The invention can also save the consumption of the lubricant, thereby achieving the effect of environmental protection. The invention has the advantages of accessible product raw materials, scientific formula, simple production technique, low cost and favorable properties, and is especially suitable for lubricating advanced gasoline engine automobiles at present.

Owner:浙江稀瓷域机械科技有限公司

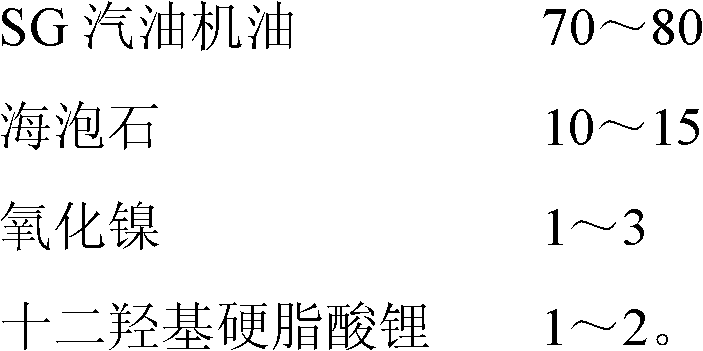

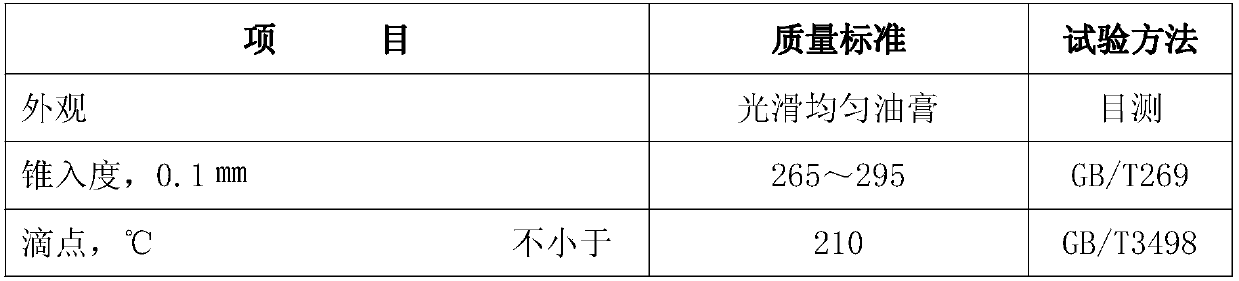

Modified fibrolite for high-temperature-resistant polyvinyl chloride cable material and preparing method of thereof

InactiveCN105482293AImprove high temperature resistanceImprove mechanical propertiesInsulated cablesInsulated conductorsDiphenylmethaneHydroxystearic Acid

The invention discloses modified fibrolite for a high-temperature-resistant polyvinyl chloride cable material and a preparing method thereof. The modified fibrolite is prepared from, by weight, 30-40 parts of fibrolite, 16-24 parts of flint clay, 10-15 parts of bauxite, 5-10 parts of lithopone, 5-10 parts of crystalline graphite powder, 4-8 parts of diphenylmethane bismaleimide, 6-12 parts of trioctyl trimellitate, 5-10 parts of dioctyl azelate, 2-4 parts of pentaerythritol monolaurate, 1-2 parts of lithium 12-hydroxystearate, 3-6 parts of poly-alpha-olefin, 1-2 parts of zinc dibutyl dithiocarbamate, 1-2 parts of diallyl bisphenol A and 4-8 parts of compound additive. The modified fibrolite has excellent high temperature resistance and the excellent mechanical performance; meanwhile, binding with an interface of a high polymer matrix is good, the heat stability, the wear resistance, the chemical corrosion resistance and the aging resistance of a composite material can be improved, and the service life of the material is prolonged.

Owner:ZHONGGUAN CABLE CO LTD

Motor lubricating oil and preparation method thereof

InactiveCN104789308APlay a role in lubrication protectionWill not corrodeAdditivesPolyethylene oxideLithium 12-hydroxystearate

The invention discloses motor lubricating oil and a preparation method thereof. The motor lubricating oil is prepared from base oil, an anti-oxidant, heptadecenyl imidazoline alkenyl succinate, tritolyl phosphate, alkyl naphthalene, methyl silicone oil, polyethylene oxide and lithium 12-hydroxystearate, wherein the weight-average molecular weights of polyethylene oxide and alkyl naphthalene are 1000-3000 and 2000-4000 respectively. The motor lubricating oil is high in viscosity and kinematic viscosity index, and has a pH value of 6-8; the preparation method of the motor lubricating oil is simple, and raw materials are easy to obtain.

Owner:ANHUI YUANFENG PIPELINE TECH CO LTD

High-temperature lithium-based lubricating grease and preparation method thereof

InactiveCN107760431AImprove performanceImprove structural stabilityLubricant compositionFriction reductionAntioxidant

The invention relates to high-temperature lithium-based lubricating grease. The high-temperature lithium-based lubricating grease is prepared from the following raw materials in parts by weight: 80 to100 parts of mineral base oil, 3 to 5 parts of lithium stearate, 7 to 15 parts of lithium 12-hydroxystearate, 0.5 to 2 parts of an extreme pressure anti-wear additive, 1 to 3 parts of a solid additive, 0.2 to 0.8 part of an antioxidant, 0.1 to 0.5 part of an anti-rust agent, 0.1 to 0.5 part of an anti-corrosion agent, 0.2 to 0.8 part of an oily agent, 0.2 to 0.8 part of a flame retardant and 1 to2 parts of a stabilizer. The lithium-based lubricating grease provided by the invention has excellent comprehensive performance; the stabilizer is added so that the structure stability of the lubricating grease is improved, and properties including the colloid stability, the mechanical stability, the water resistance and the like of the lubricating grease are greatly improved; the extreme pressure anti-wear additive and the solid additive, which have a mutual synergistic effect, are added so that the lubricating grease has relatively good friction reduction performance and anti-wear performance and relatively good stability; the energy consumption of equipment in an operation process and abrasion on the equipment are easy to reduce and the service life of the equipment is prolonged. Meanwhile, the high-temperature lithium-based lubricating grease has good anti-oxidization performance and anti-rust and anti-corrosion performance.

Owner:安徽中天石化股份有限公司

Anti-freezing lubricating oil

InactiveCN108148651AStable in natureImprove the lubrication effectAdditivesHydroxystearic AcidAnti coagulation

The invention discloses anti-freezing lubricating oil, and belongs to the technical field of fine chemical engineering. The anti-freezing lubricating oil is prepared from the following raw materials in parts by weight: 80-100 parts of base oil, 4-5 parts of dodecyl acidic phosphite, 3-4 parts of unsaturated fatty acid, 2-3 parts of glyceryl acrylate, 3-8 parts of ethylene glycol, 1-3 parts of lithium 12-hydroxystearate, 0.1-2 parts of sodium dodecyl sulfate and 0.5-3 parts of oleamide. The lubricating oil special for an engine provided by the invention is stable in property, and the auxiliaryadditives can optimize the lubricating, anti-corrosion, anti-coagulation, anti-oxidation and pressure-resisting performance of the base oil, the cleaning performance is good, and oil sludge and carbondeposit can be reduced. Meanwhile, the anti-freezing lubricating oil can be used at a low temperature (higher than or equal to -30 DEG C).

Owner:QINGDAO RONGHE TIANZE CULTURE TECH CO LTD

Lubricating oil for motor and preparation method thereof

InactiveCN104830410APlay a role in lubrication protectionWill not corrodeAdditivesPolyethylene oxideAntioxidant

Owner:ANHUI YUANFENG PIPELINE TECH CO LTD

Lubricating grease for underwater spindle noses of iron-making auger conveyors and preparation method

InactiveCN106497639ADrop point highNot easy to loseLubricant compositionNoseLithium 12-hydroxystearate

The invention relates to lubricating grease for underwater spindle noses of iron-making auger conveyors and a preparation method. The lubricating grease comprises base oil, densifiers, viscosity index improvers, extreme-pressure antiwear agents and antirust agents. The preparation method includes adding composite soap, namely the densifiers, and 45-55% of the base oil into a reaction kettle, stirring and heating to the temperature of 220-230 DEG C, keeping the constant temperature for 25 minutes, adding 10-20% of the base oil for cooling, continuing to stir, adding the residual base oil, stirring to cool the temperature to below 70 DEG C, adding additives, and stirring and mixing evenly, wherein the mass ratio of lithium 12-hydroxystearate to calcium 12-hydroxystearate to lithium octanedioic acid in the composite soap is 3:1:1. The lubricating grease prepared according to the preparation method has high dropping point, and friction and abrasion of lubricated portions are reduced during work under certain heavy load conditions; the lubricating grease has good waterproofing performance and good salt mist and rust resistance performance; the condensation point of the base oil is low, and a certain pumping performance of the lubricating grease is guaranteed; high-temperature loss of the lubricating grease is avoided, and extreme-pressure antiwear performance, salt mist and rust resistance performance, water-adding anti-shearing performance, pumping performance and the like of the lubricating grease are realized.

Owner:CHINA PETROLEUM & CHEM CORP

Composite lithium-base grease and method for making same

ActiveCN101200670BGood colloidal stabilityGood mechanical stabilityThickenersAdditivesAntioxidantHydroxystearic Acid

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive.The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 : 0.1 to 1 : 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent,dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener andthe base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point,good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing functiontowards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Lubricating grease composition

InactiveCN104513694AGood oil resistanceLubricant compositionPolymer scienceLithium 12-hydroxystearate

The present invention provides a lubricating grease composition with high mechanical shear stability. The lubricating grease composition is characterized in that a fatty acid lithium-based thickener obtained by mixing lithium stearate and 12-hydroxy lithium stearate, and more than one additives containing phosphorus and / or sulfur are matched and mixed in a base oil.

Owner:JX NIPPON OIL & ENERGY CORP

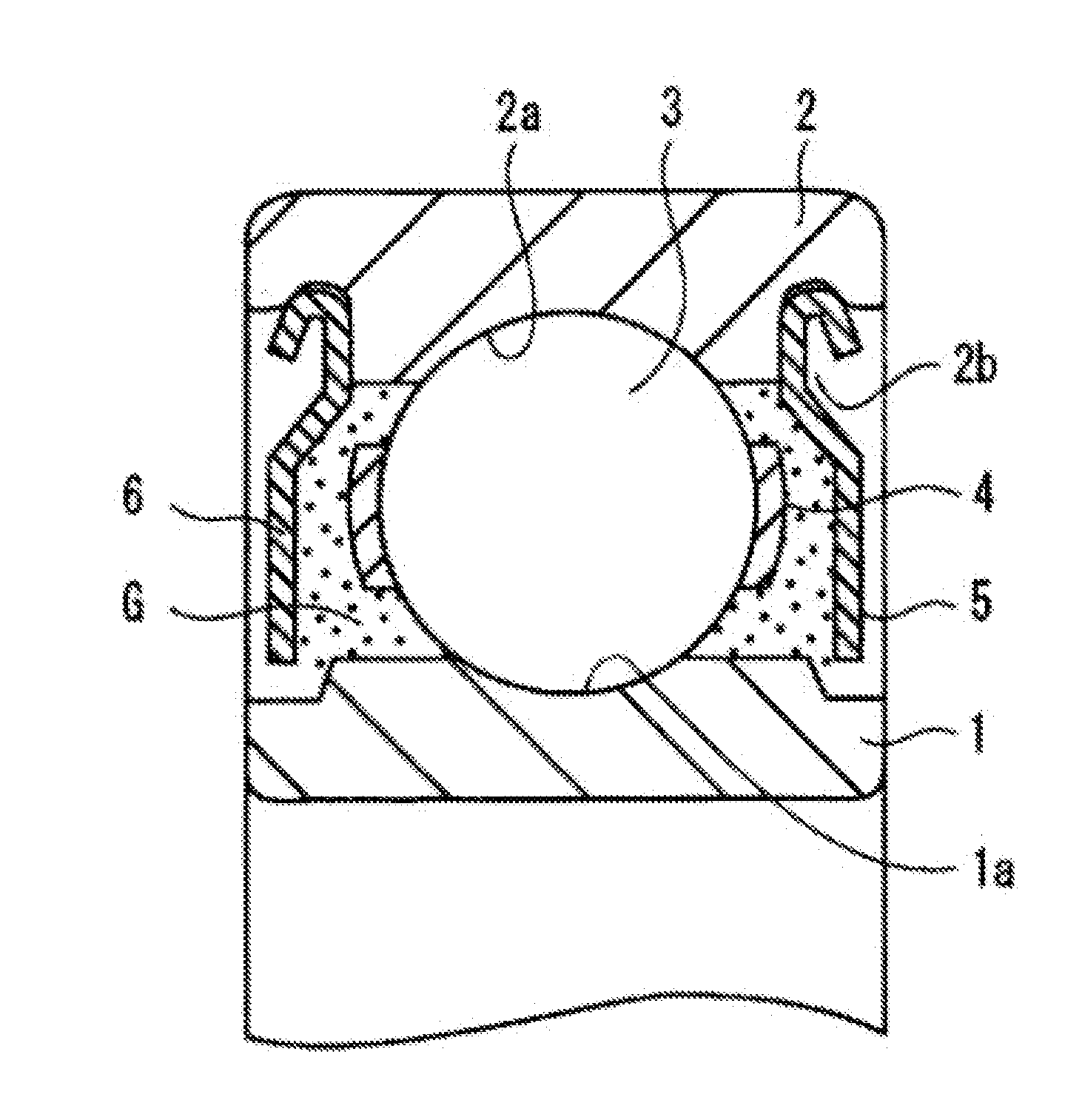

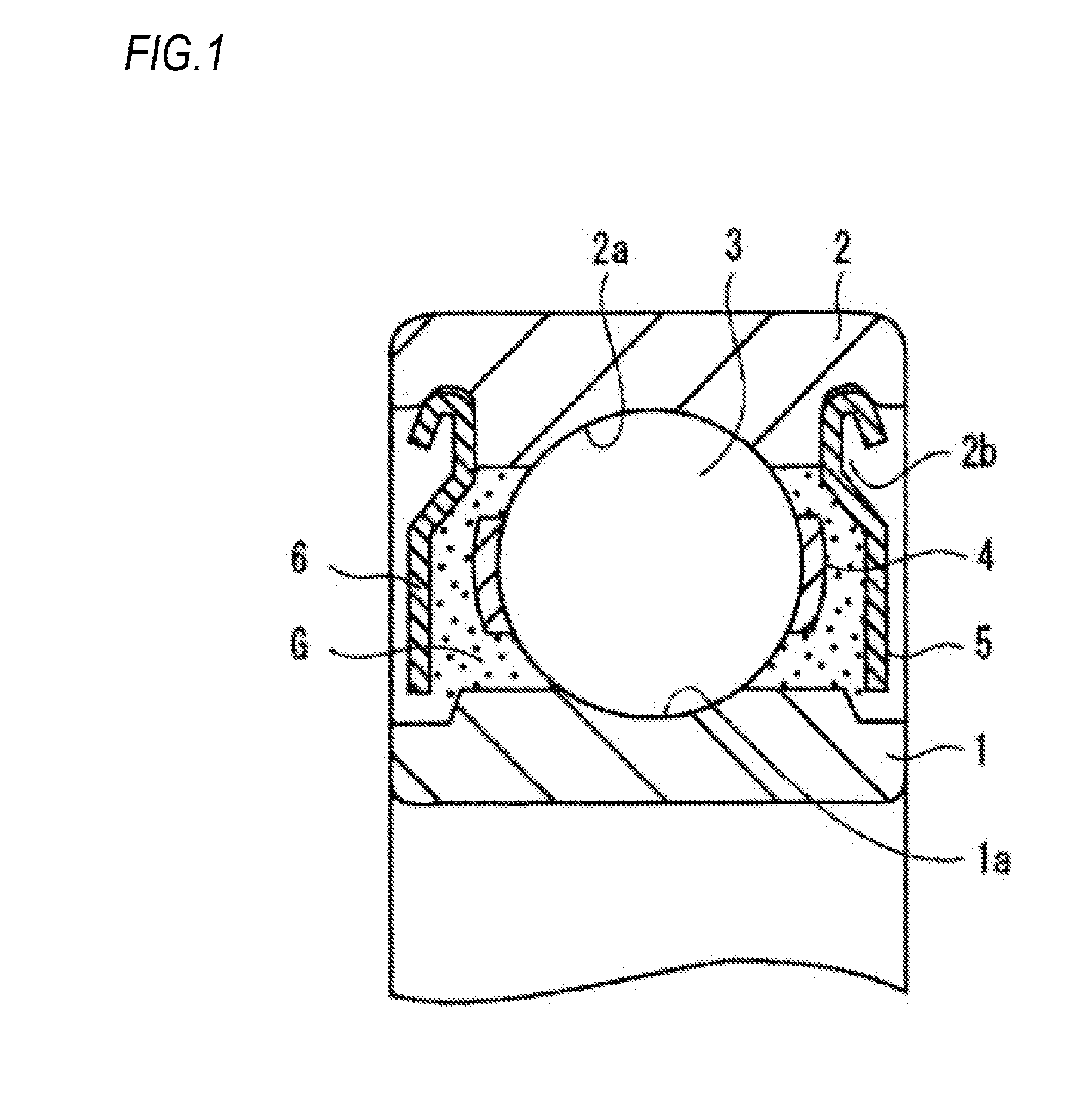

Rolling device

InactiveUS20160201726A1Improve acoustic propertiesPrevent leakageShaftsBall bearingsCarbon numberLithium 12-hydroxystearate

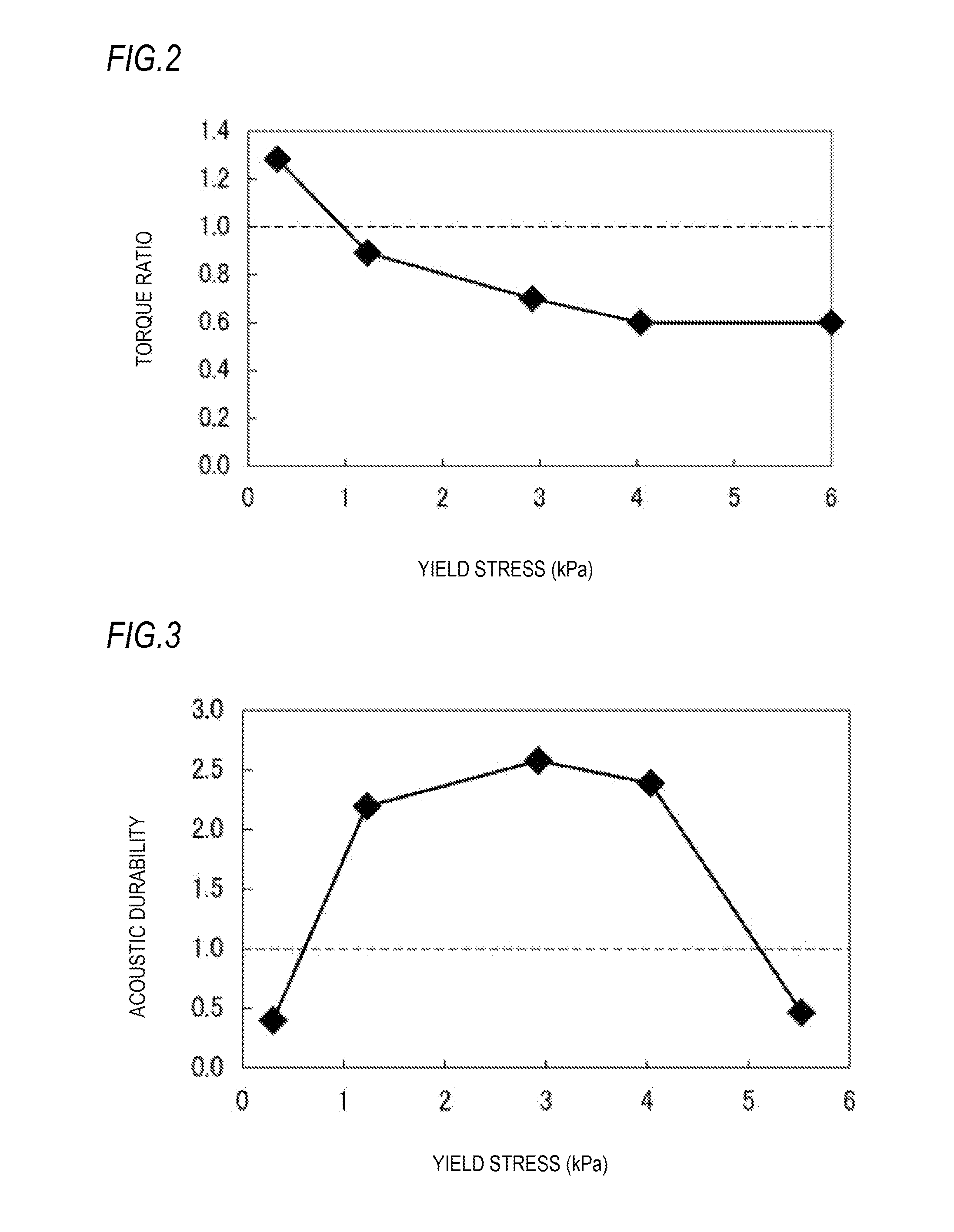

In the rolling device of the present invention, a grease composition is enclosed which contains a base oil having a kinematic viscosity of 15 to 80 mm2 / s at 40° C. and, as a thickener, a mixture of lithium 12-hydroxystearate and a lithium fatty acid having a carbon number of 6 to 12, and has a dropping point of 190 to 240° C. and a yield stress of 1.2 to 5 kPa. Accordingly, the torque is reduced and the acoustic life is improved.

Owner:NSK LTD +1

Warm molding raw material powder and warm molding method

InactiveUS7582255B2Improve liquidityHigh propertyTransportation and packagingMetal-working apparatusMetallurgyLithium 12-hydroxystearate

A hydroxy fatty acid salt having an average particle diameter of from 5 μm to 100 μm with a composition of from 0.3 wt % to 2 wt %, and more preferably, from 0.5 wt % to 2 wt % is added to a raw material powder in powder metallurgy, and worm molding is performed. In addition, a hydroxy fatty acid salt having an average particle diameter of 50 μm or less is attached on a mold in advance, and after that, the warm molding is performed. As a hydroxy fatty acid salt, 12-hydroxy lithium stearate is suitably used.

Owner:DIAMET CORP

Bearing lubricating grease and preparation method thereof

ActiveCN102977978BHigh dropping point temperatureNot collapseLubricant compositionAntioxidantLithium hydroxide

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

Formula of wear-resistant material surface coating

The invention relates to a formula of a wear-resistant material surface coating. The formula of the wear-resistant material surface coating is composed of raw materials including, by weight percentage, 5-15% of base oil III, 1-5% of epoxidized soybean oil, 1-10% of benzotriazole, 5-15% of nano-onion-like carbon, 3-9% of polyol ester, 2-3% of lithium 12-hydroxystearate, 1-5% of nickel oxide, 11-19%of sepiolite, 5-7% of fatty alcohol polyoxyethylene ether, 3-5% of high-basicity magnesium sulfonate, 3-5% of high-basicity calcium sulfonate, 1-5% of calcium alkyl sulfide and 5-10% of zinc dithiophosphate alkyl sulfide. The wear-resistant material surface coating is high in wear-resistant and antioxidant performance.

Owner:徐州市恩矿新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com