Lithium-based lubricating grease composition and preparation method for same

A grease composition and technology of lithium-based grease are applied in the field of grease to achieve the effects of increasing service life, improving product performance and improving structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

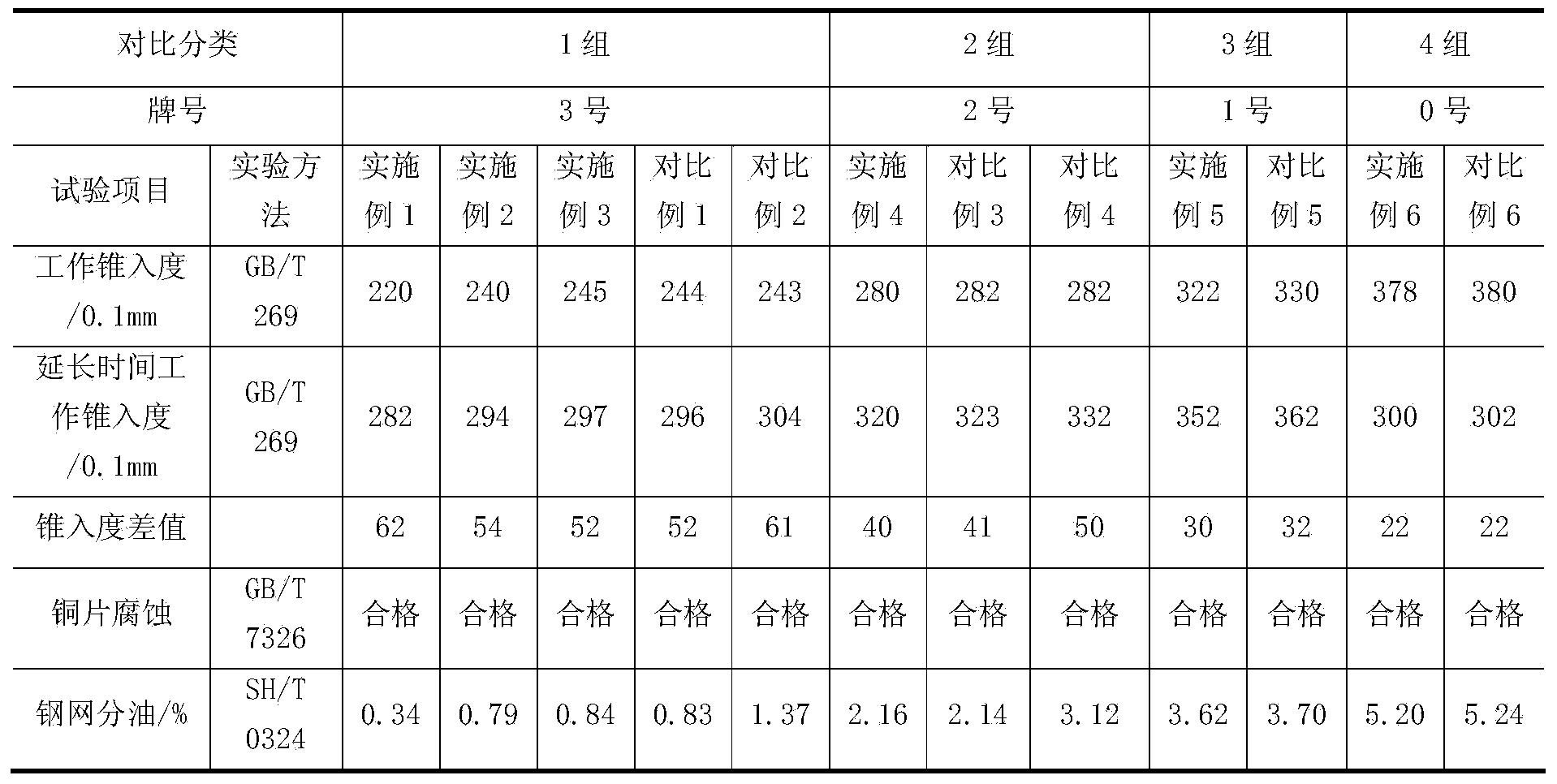

Examples

Embodiment 1

[0028] Lithium base lubricating grease composition component and mass percent are as follows:

[0029] (1) Lithium 12-hydroxystearate soap 9.0%;

[0030] (2) Lithium stearate soap 2.5%;

[0031] (3) High acid value mineral base oil 10.0%;

[0032] (4) Ordinary mineral base oil 78.0%;

[0033] (5) Diphenylamine 0.46%;

[0034] (6) Benzotriazole 0.04%.

[0035] The process is: high acid value mineral base oil (acid value 7.5mgKOH / g, 100°C kinematic viscosity 10-12mm 2 / s) 100.0g, 300.0g of common mineral base oil were put into the kettle, 90.0g of 12-hydroxy lithium stearate soap and 25.0g of lithium stearate soap were added. Add 200.0g of ordinary mineral base oil and heat up and stir. When the temperature rises to 210-220°C, stop heating and keep the temperature for 5 minutes; stir and add 280.0g of ordinary mineral base oil, and perform rapid cooling; when the temperature is 140-150°C, add 4.6g of diphenylamine , Benzotriazole 0.4g; Stir evenly, take out of the kettle, ...

Embodiment 2

[0037] Lithium base lubricating grease composition component and mass percent are as follows:

[0038] (1) Lithium 12-hydroxystearate soap 8.1%;

[0039] (2) Lithium stearate soap 2.25%;

[0040] (3) High acid value mineral base oil 35.0%;

[0041] (4) Ordinary mineral base oil 54.4%;

[0042] (5) Diphenylamine 0.2%;

[0043] (6) Benzotriazole 0.05%.

[0044] The process is: high acid value mineral base oil (acid value 3.26mgKOH / g, 100°C kinematic viscosity 19.96mm 2 / s) 350.0g, 50.0g of ordinary mineral base oil were put into the kettle, 81.0g of 12-hydroxy lithium stearate soap and 22.5g of lithium stearate soap were added. Add 200.0g of ordinary mineral base oil and heat up and stir. When the temperature rises to 210-220°C, stop heating and keep the temperature for 5 minutes; stir and add 294.0g of ordinary mineral base oil for rapid cooling; when the temperature is 140-150°C, add 2.0g of diphenylamine , Benzotriazole 0.5g. Stir evenly, take it out of the kettle, and...

Embodiment 3

[0046] Lithium base lubricating grease composition component and mass percent are as follows:

[0047] (1) Lithium 12-hydroxystearate soap 7.7%;

[0048] (2) Lithium stearate soap 2.13%;

[0049] (3) High acid value mineral base oil 28.0%;

[0050] (4) Ordinary mineral base oil 61.35%;

[0051] (5) Diphenylamine 0.8%;

[0052] (6) Benzotriazole 0.02%.

[0053] The process is: high acid value mineral base oil (acid value 2.41mgKOH / g, 100°C kinematic viscosity 23.61mm 2 / s) 280.0g, 120.0g of ordinary mineral base oil were put into the kettle, 77.0g of 12-hydroxy lithium stearate soap and 21.3g of lithium stearate soap were added. Add 200.0g of ordinary mineral base oil and heat up and stir. When the temperature rises to 210-220°C, stop heating and keep the temperature for 5 minutes; stir and add 293.5g of ordinary mineral base oil for rapid cooling; when the temperature is 140-150°C, add 8.0g of diphenylamine , Benzotriazole 0.2g; Stir evenly, take out of the kettle, and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com