Low-temperature lubricating grease and preparation method thereof

A low-temperature lubrication and fatty acid soap technology, applied in the field of grease, can solve the problems of high volatility, poor high temperature performance and high cost of synthetic oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

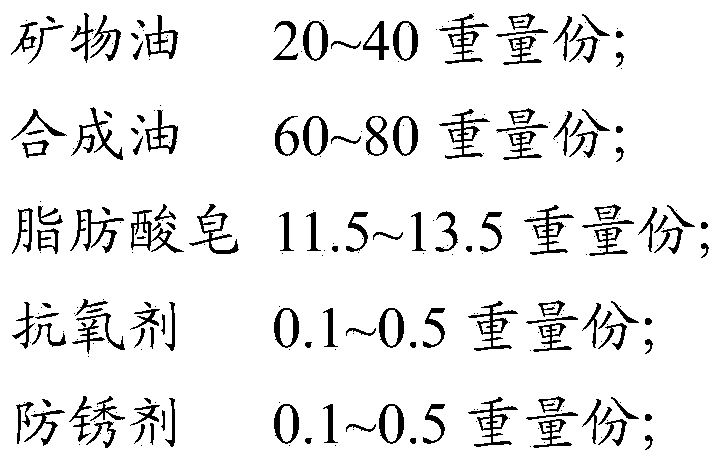

[0047] The present invention also provides a preparation method of the above-mentioned low-temperature lubricating grease, comprising the following steps: A) 20-40 parts by weight of mineral oil, 60-80 parts by weight of synthetic oil, 11.5-13.5 parts by weight of fatty acid soap, 0.1-0.5 parts by weight The anti-oxidant in parts by weight is mixed with 0.1-0.5 parts by weight of anti-rust agent, heated and stirred to obtain low-temperature lubricating grease;

[0048] The mineral oil is Group III oil;

[0049] The synthetic oil is ester oil and / or PAO;

[0050] Described fatty acid soap is the mixture of lithium stearate and 12-hydroxyl stearate;

[0051] The antioxidant is selected from one or more of alkylphenol antioxidants and aromatic amine antioxidants;

[0052] The antirust agent is selected from one of sulfonate compounds, alkenyl succinic acid antirust agents, higher fatty acids, higher fatty acid salts, thiadiazole antirust agents and benzotriazole antirust agents...

Embodiment 1

[0060] Add 78.3g of mineral oil 100N, 130.5g of PAO4, 52.2g of di-octyl sebacate and 39g of fatty acid soap (mass ratio of lithium stearate to lithium 12-hydroxystearate is 7:3) into the reactor , heated to 200°C, the system formed a true solution, stopped heating, added 0.9g benzotriazole and 1.5g diphenylamine, stirred for 2 minutes, poured it into an aluminum plate (area: 40cm×70cm), cooled to room temperature and used The three-roll mill grinds three times to obtain low-temperature lubricating grease.

[0061] The performance of the low-temperature lubricating grease obtained in Example 1 is analyzed, and the test results are shown in Table 1.

Embodiment 2

[0063] Add 78.3g of mineral oil 100N, 130.5g of PAO4, 52.2g of di-octyl sebacate and 39g of fatty acid soap (mass ratio of lithium stearate to lithium 12-hydroxystearate is 6.5:3.5) into the reactor , heated to 200°C, the system formed a true solution, stopped heating, added 0.9g benzotriazole and 1.5g diphenylamine, stirred for 2 minutes, poured it into an aluminum plate (area: 40cm×70cm), cooled to room temperature and used The three-roll mill grinds three times to obtain low-temperature lubricating grease.

[0064] The performance of the low-temperature lubricating grease obtained in Example 2 was analyzed, and the test results were shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com