Lubricating grease composition

A technology of grease composition and lithium stearate, applied in lubricating composition, petroleum industry, etc., can solve the problems of fluidity, oil separation, heat resistance, water resistance, shear stability, etc., and achieve oil separation resistance High, stable sliding characteristics, stable reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

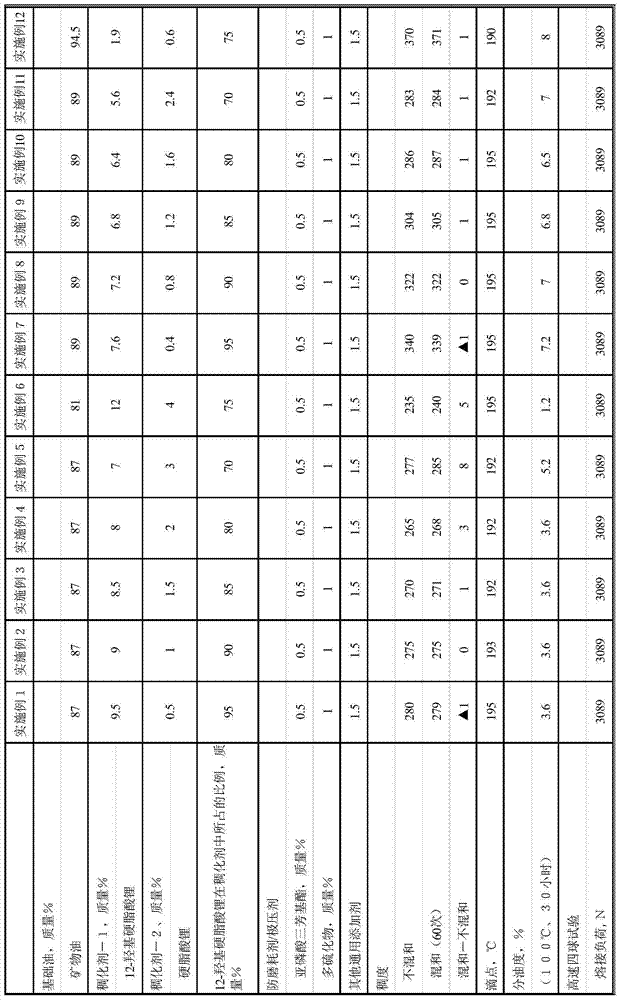

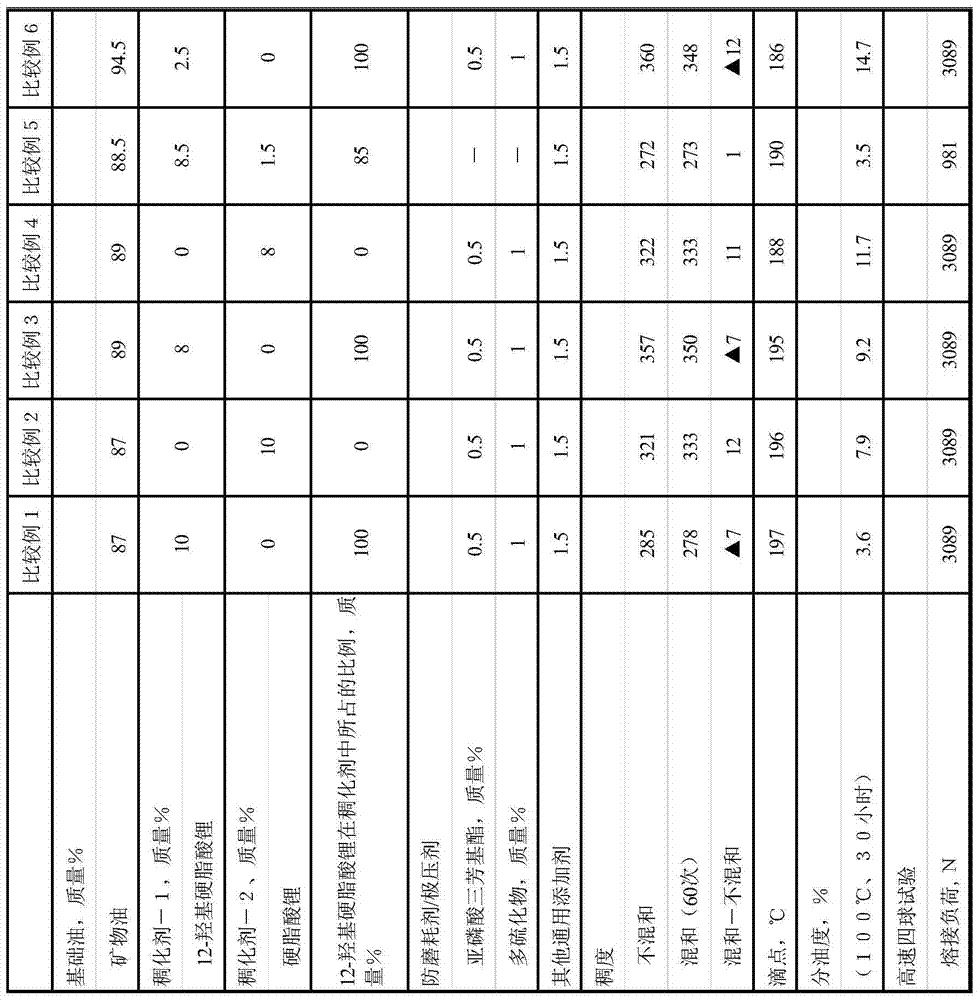

Embodiment 1~12、 comparative example 1~6

[0062] In Examples 1 to 12 and Comparative Examples 1 to 6, the base oil, the thickener, and each additive were put into a stainless steel container in the compounding amounts (expressed in mass %) shown in Tables 1 to 2, and heated to about 220°C to dissolve evenly. After cooling, when it became a semi-solid state, pressurized dispersion treatment was performed with a roll (three-roll mill) to obtain a grease composition having the composition shown in Tables 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com