Positive electrode material for non-aqueous electrolyte lithium ion battery and battery using the same

A technology of lithium-ion batteries and non-aqueous electrolytes, applied in battery electrodes, secondary batteries, secondary battery manufacturing, etc., can solve problems such as electrolyte decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-42、85、86 and comparative example 1 and 2

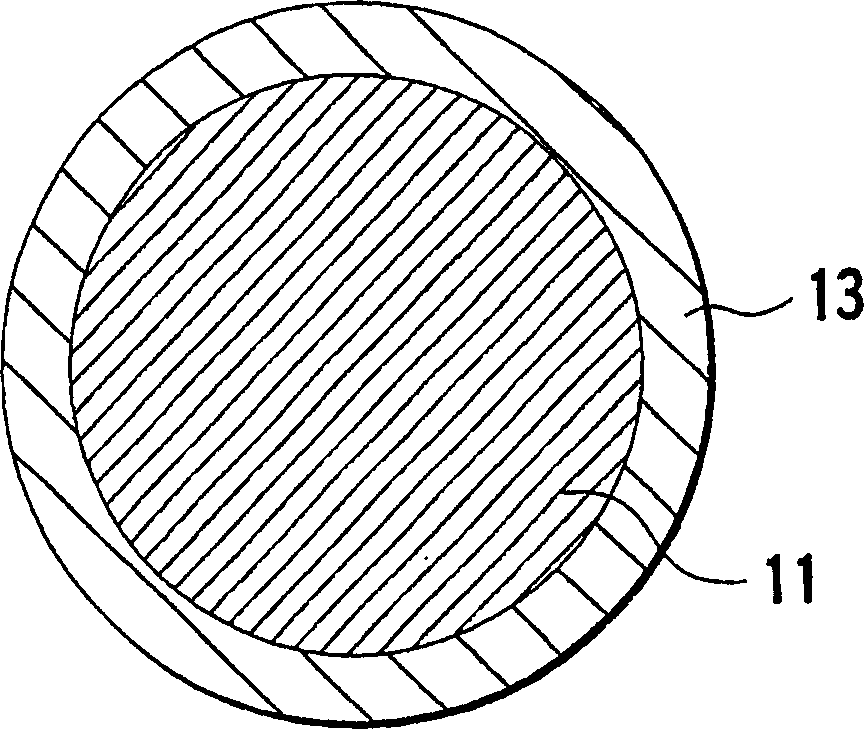

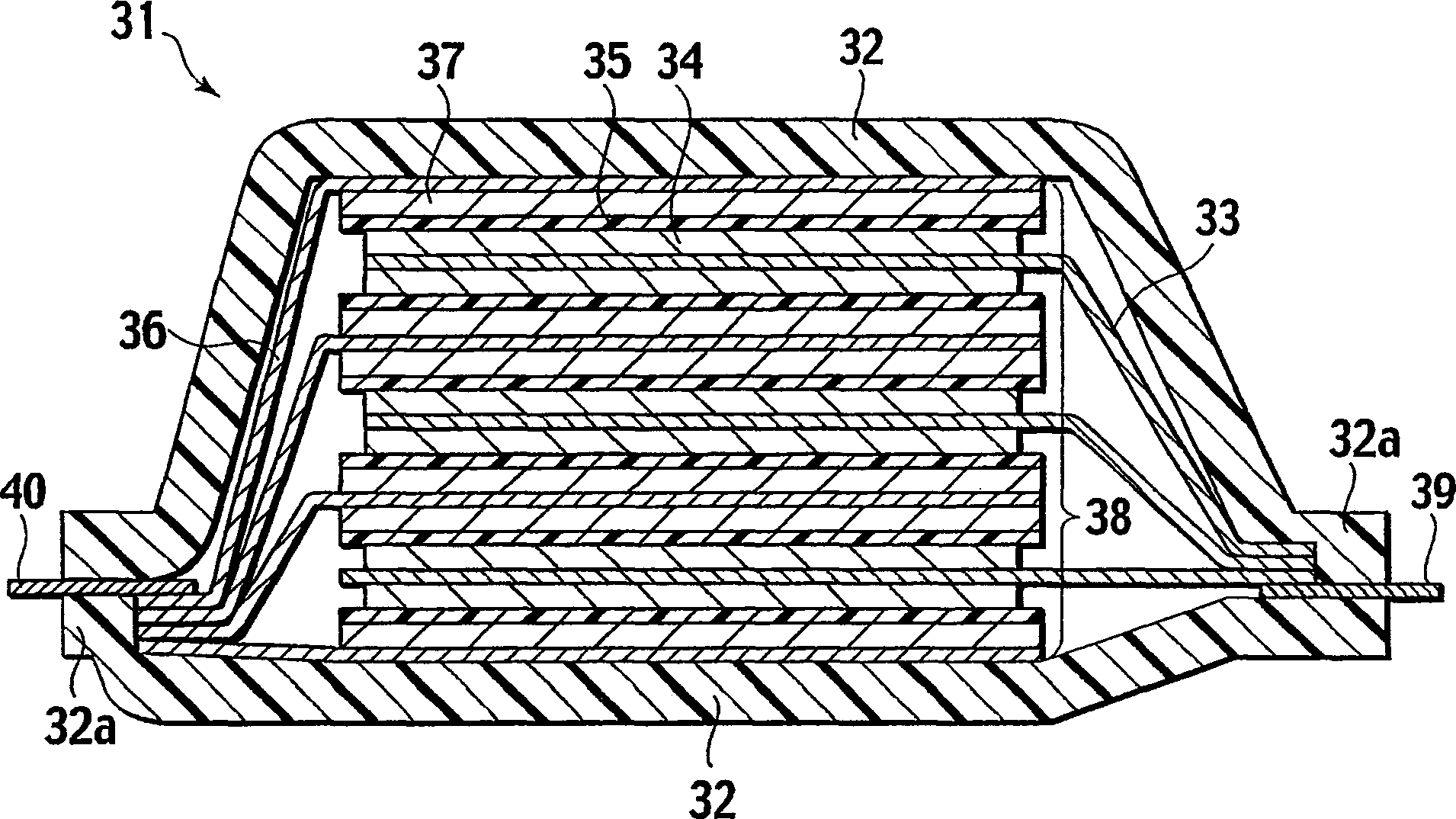

[0118] 1. Preparation of Cathode

[0119] First, if Figure 10 and 11 As shown, substances (Examples 1-42, 85 and 86) and Li-Ni oxide ( Comparative Example 1-2, Li compound was not deposited). A slurry was prepared by adding N-methyl-2-pyrrolidone as a solvent, stirring 75% by mass of Li-Ni oxide, 10% by mass of acetylene black as a conductive material, and 15% by mass of polyvinylidene fluoride. This slurry was covered with an applicator on an aluminum foil (thickness: 20 μm) as a positive electrode current collector, and heated and dried in a vacuum dryer at about 80° C. Next, electrodes with a diameter of 15 mm were punched out from the aluminum foil, and then dried at 90° C. under high vacuum for 6 hours. The thickness of the punched positive electrode active material layer was 50 μm. As for the method of covering the Li-Ni oxide with the Li compound, the Li-Ni oxide was covered with the Li compound so as to have a covering thickness of 500 nm by a mechanical melting ...

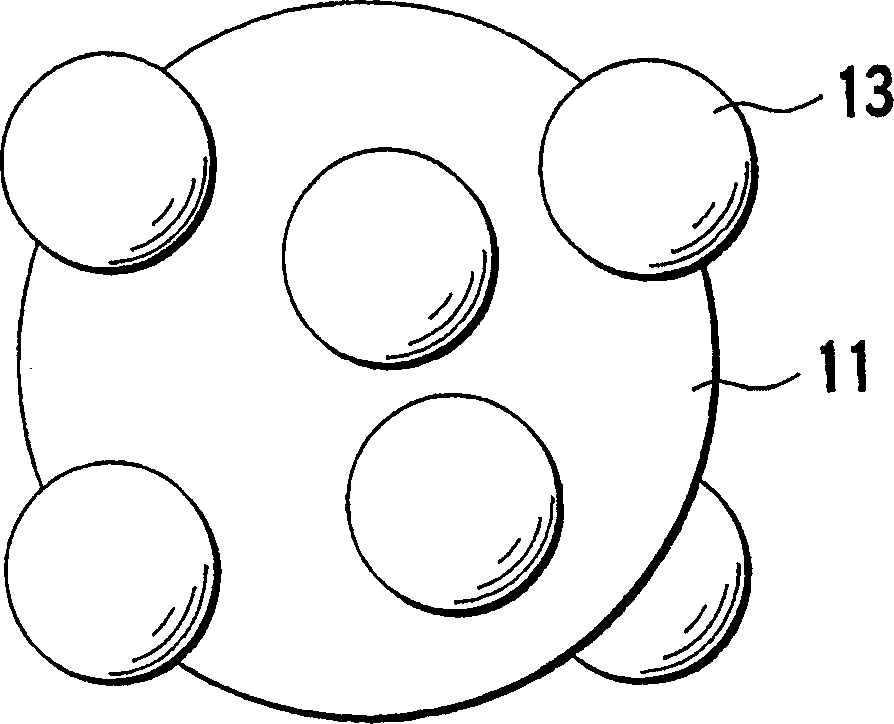

Embodiment 43-84、87、88 and comparative example 3 and 4

[0127] First, if Figure 12 and 13 As shown, substances each containing a Li compound deposited so as to be sprayed on the surface of Li-Ni oxide (average particle diameter: 8 μm) such that its volume was 1 volume relative to 100 volumes of Li-Ni oxide were prepared (Example 43-84, 87 and 88). Also, Li—Ni oxide (average particle diameter: 8 μm) was prepared (Comparative Examples 3 and 4, no Li compound was deposited). Except for this, positive and negative electrodes and batteries were prepared and evaluated in the same manner as in Examples. The results obtained are shown in Figure 12 and 13 middle.

[0128] from Figure 10 to Figure 13 It can be confirmed that, compared with each comparative example in which the Li compound is not deposited on the surface of the Li-Ni oxide, in any of the examples including the substance in which the Li compound is deposited on the surface of the Li-Ni oxide as the positive electrode material, it is possible to Suppresses battery swe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com