Highly biodegradable construction machinery lubricating grease and preparation method thereof

A biodegradable, construction machinery technology, applied in the field of construction machinery lubricating grease and preparation, to achieve good market application prospects, improve adhesion and sealing, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

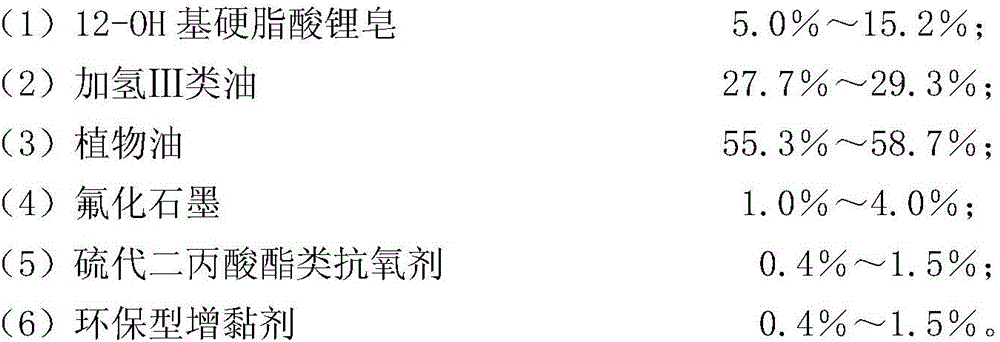

[0025] Highly biodegradable construction machinery grease composition, components and mass percentages are as follows:

[0026]

[0027] Hydrogenated Group III oil (100°C kinematic viscosity 6.5mm 2 / s) 293g was put into the kettle, the temperature was raised to 60°C, 50g of 12-hydroxy lithium stearate soap was added, and the material was stirred for 30min to disperse. Add soybean oil 176g and heat up material. When the temperature rises to 210-220°C, stop heating and keep stirring for 5 minutes at the temperature. Put the remaining soybean oil into the kettle to cool the material rapidly. When the temperature reaches 120°C, add 40 g of graphite fluoride, 15 g of dilauryl thiodipropionate, and 15 g of polymethacrylate. Stir evenly, you can get out of the kettle. Finally, the finished product is obtained after grinding 3 times with a three-roll mill. The properties of the grease obtained are shown in Table 1.

Embodiment 2

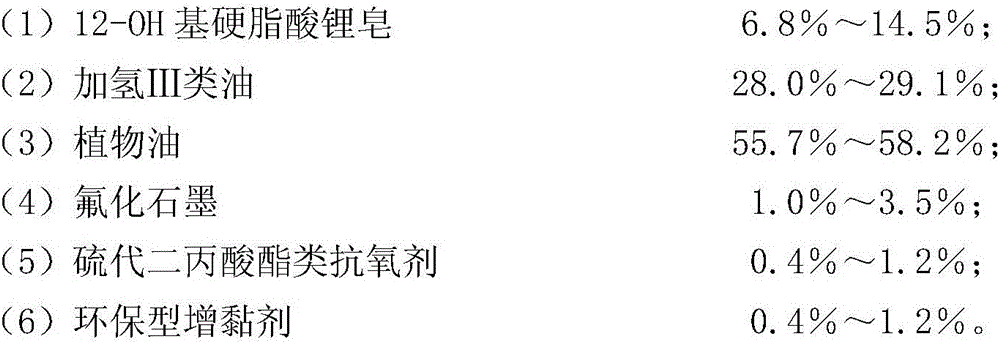

[0029] Highly biodegradable construction machinery grease composition, components and mass percentages are as follows:

[0030]

[0031] Hydrogenated Group III oil (100°C kinematic viscosity 8.5mm 2 / s) 277g was put into the kettle, the temperature was raised to 95°C, 12-hydroxy lithium stearate soap was added, and stirred for 10min to disperse the material. Add 352g of oxidized rapeseed oil and heat up the material. When the temperature rises to 210-220°C, stop heating and keep stirring for 1 min at the temperature. Put the remaining oxidized rapeseed oil into the kettle to cool the material rapidly. When the temperature reaches 85°C, add 10 g of graphite fluoride, 4 g of bis-stearyl thiodipropionate, and 4 g of natural rubber. Stir evenly, you can get out of the kettle. Finally, the finished product is obtained after grinding 3 times with a three-roll mill. The properties of the grease obtained are shown in Table 1.

Embodiment 3

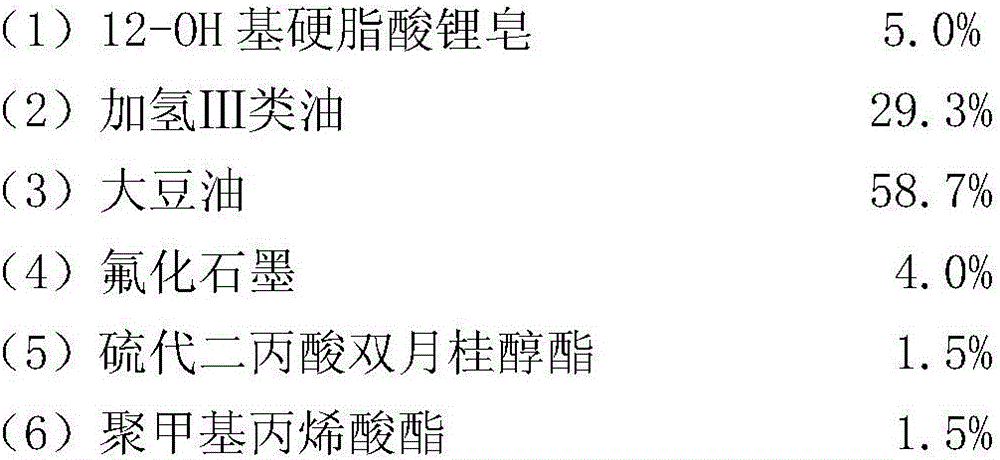

[0033] Highly biodegradable construction machinery grease composition, components and mass percentages are as follows:

[0034]

[0035]

[0036] Hydrogenated Group III oil (100°C kinematic viscosity 8.5mm 2 / s) 280g was put into the kettle, the temperature was raised to 80°C, 12-hydroxy lithium stearate soap was added, and stirred for 15min to disperse the material. Add soybean oil 288g and heat up material. When the temperature rises to 210-220°C, stop heating and keep stirring for 2 minutes at the temperature. Put the remaining soybean oil into the kettle to cool the material rapidly. When the temperature reaches 100°C, add 10 g of graphite fluoride, 4 g of dilauryl thiodipropionate, and 4 g of polymethacrylate. Stir evenly, you can get out of the kettle. Finally, the finished product is obtained after grinding 3 times with a three-roll mill. The properties of the grease obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com