High temperature resisting material for communication optical cable sheath and preparation method of high temperature resisting material

A technology for communication optical cables and sheathing materials, applied in the direction of fiber mechanical structure, etc., can solve the problems affecting the normal operation of communication optical cables, decomposition and performance deterioration, poor high temperature resistance, etc., to achieve excellent high temperature resistance, excellent wear resistance, high Effects of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

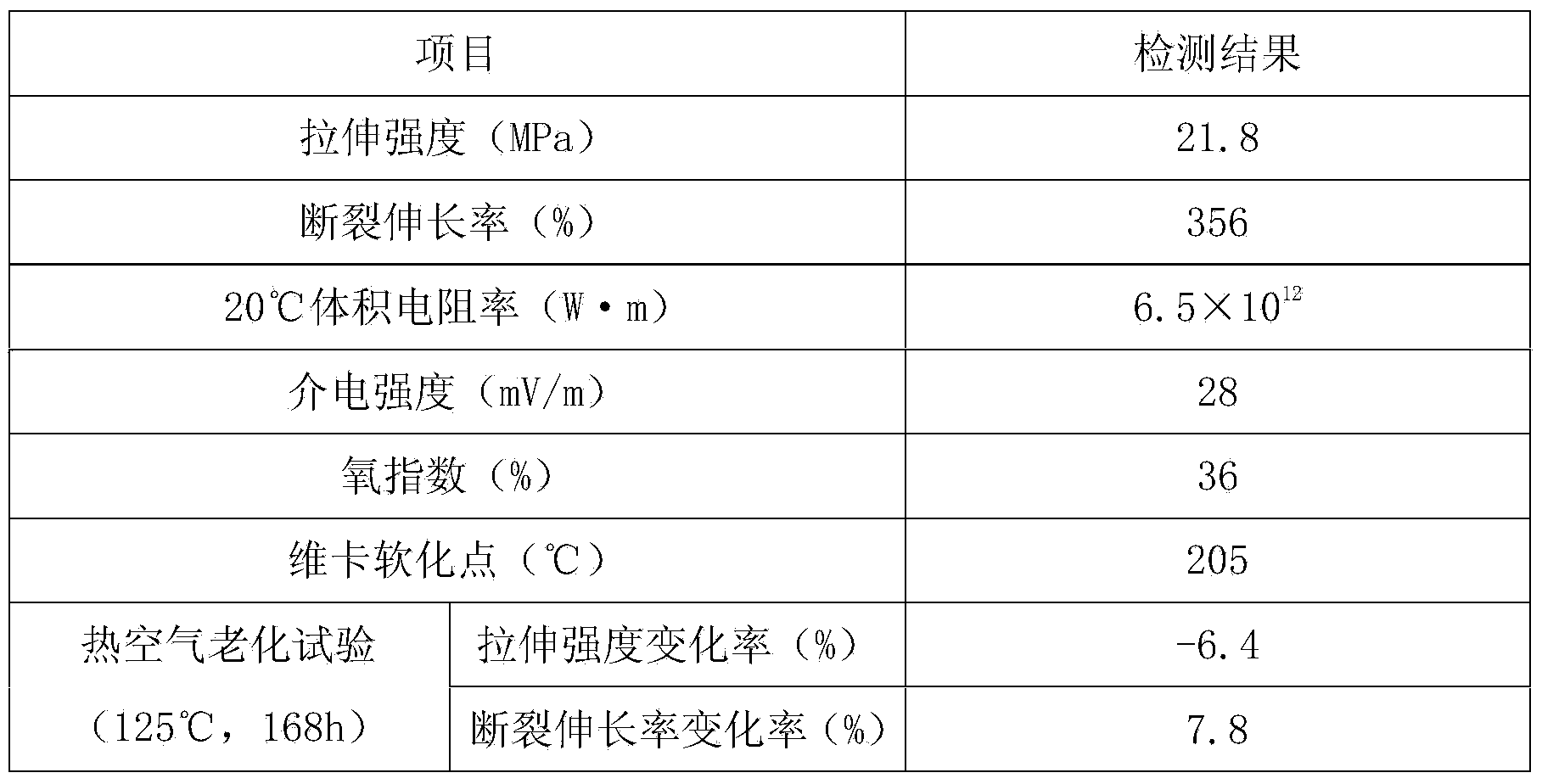

Examples

Embodiment

[0013] A high temperature resistant communication optical cable sheath material, made of the following raw materials (kg): polypropylene 60, polybenzimidazole 35, hydrated basic magnesium carbonate 18, dimethyl biphenyl diisocyanate 4, N-benzene Base maleimide 3, polytetrafluoroethylene 18, siliconized graphite 12, poly-p-phenylene terephthalamide 22, calcium molybdate 12, diisononyl phthalate 18, nano titanium phosphate 16, super Fine aluminum silicate 12, pentaerythritol phosphate 6, lithium stearate 2.5, calcium acetylacetonate 4, low molecular weight polybutene 5, 3-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate Ester 1.5, bisphenol A-bis(diphenyl phosphate) 2.5;

[0014] The preparation method of the regenerated material is as follows: (1) take the following raw materials of weight (kg): PVC waste 40, PP waste 30, ABS nozzle material 15, PETG leftover material 10, aramid pulp 5, refractory brick chips 12, powder Coal ash 8, oil shale slag 5, waste glass powder 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com