Wire rope lubricating grease composition used in low temperature environment

A technology of grease composition and low-temperature environment, which is applied in the field of grease and can solve problems such as shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

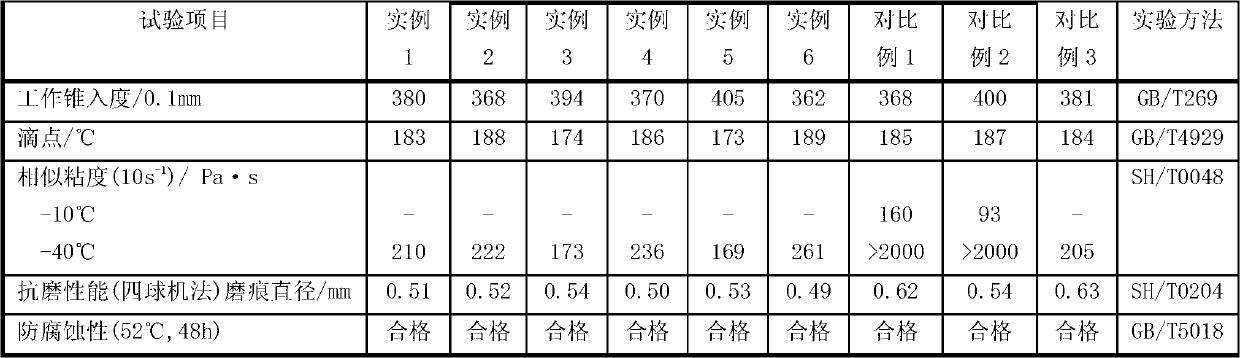

Examples

example 1

[0031] The steel wire rope grease composition used in low temperature environment, the components and mass percentages are as follows:

[0032] (1) 12-OH lithium stearate soap 4.0%;

[0033] (2) Lithium stearate soap 1.0%;

[0034] (3) Poly-α-olefin synthetic oil 91.0%;

[0035] (4) High base value synthetic calcium acid 3.0%;

[0036] (5) Colloidal graphite 1.0%.

[0037] Poly-α-olefin synthetic oil (condensation point -50°C, 100°C kinematic viscosity 9.1mm 2 / s) 360g into the kettle, add 40g of 12-OH lithium stearate soap and 10g of lithium stearate soap. Heat up and stir. When the temperature rises to 210-220°C, stop heating and keep the temperature for 2 minutes. Stir and add 550 g of polyalphaolefin synthetic oil as cooling material. When the temperature drops to 125-130°C, add 30g of high alkali value synthetic calcium acid (base value 380mgKOH / g) and 10g of colloidal graphite (particle size<25μm), and stir evenly. Out of the cauldron. Grind 3 times with a three-...

example 2

[0039] The steel wire rope grease composition used in low temperature environment, the components and mass percentages are as follows:

[0040] (1) 5.0% 12-OH lithium stearate soap;

[0041] (2) Lithium stearate soap 1.2%;

[0042] (3) Polyalphaolefin synthetic oil 88.3%;

[0043] (4) High base value synthetic calcium acid 4.0%;

[0044] (5) Colloidal graphite 1.5%.

[0045] Polyα-olefin synthetic oil (condensation point -54 ° C, 100 ° C kinematic viscosity 7.5mm 2 / s) 400g into the kettle, add 50g of 12-OH lithium stearate soap and 12g of lithium stearate soap, heat up and stir, when the temperature rises to 210-220°C, stop heating and keep the temperature for 2min. Stir and add 483g of polyalphaolefin synthetic oil as cooling material. When the temperature drops to 125-130°C, add 40g of high alkali value synthetic calcium acid (base value 350mgKOH / g) and 15g of colloidal graphite (particle size<25μm), and stir evenly. Out of the cauldron. Grind 3 times with a three-rol...

example 3

[0047] The steel wire rope grease composition used in low temperature environment, the components and mass percentages are as follows:

[0048] (1) 3.6% 12-OH lithium stearate soap;

[0049] (2) Lithium stearate soap 0.9%;

[0050] (3) Poly-α-olefin synthetic oil 92.0%;

[0051] (4) 2.5% high base value synthetic calcium acid;

[0052] (5) Colloidal graphite 1.0%.

[0053] Poly-α-olefin synthetic oil (condensation point -54 ° C, 100 ° C kinematic viscosity 7.0mm 2 / s) 276g was put into the kettle, 36g of 12-OH lithium stearate soap and 9g of lithium stearate soap were added. Stir and heat up. When the temperature rises to 210-220°C, stop heating and keep the temperature for 4 minutes. Stir and add 644g of polyalphaolefin synthetic oil as cooling material. When the temperature drops to 125-130°C, add 25g of high alkali value synthetic calcium acid (base value 300mgKOH / g) and 10g of colloidal graphite (particle size<30μm), and stir evenly. Out of the cauldron. Grind 3 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com