Steel wire rope lubricating grease composition for low-temperature environments

A lubricating grease composition and technology of the composition, applied in lubricating compositions, petroleum industry, etc., can solve the problems of poor low temperature resistance of lubricating grease, shortened life of steel wire rope, falling off, etc., achieve excellent low temperature resistance and solve poor permeability , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

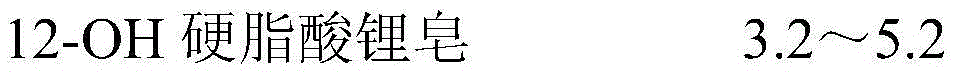

[0028] A kind of steel wire rope grease composition for low temperature environment, described composition comprises by weight parts:

[0029]

[0030] Said polyalphaolefin synthetic oil has a kinematic viscosity of 8-11mm at 100°C 2 / s.

[0031] The particle size of the colloidal graphite is less than 20 μm.

Embodiment 2

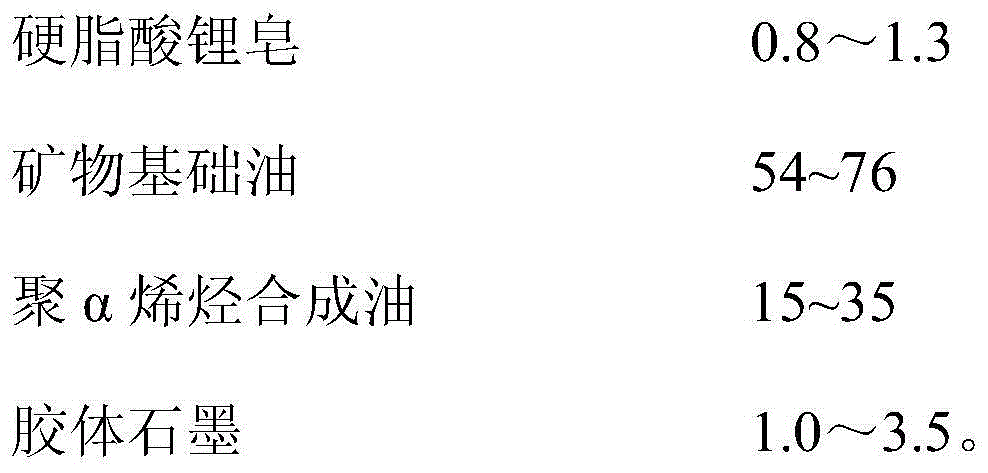

[0033] A kind of steel wire rope grease composition for low temperature environment, described composition comprises by weight parts:

[0034]

[0035] Said polyalphaolefin synthetic oil has a kinematic viscosity of 8-11mm at 100°C 2 / s.

[0036] The particle size of the colloidal graphite is less than 20 μm.

Embodiment 3

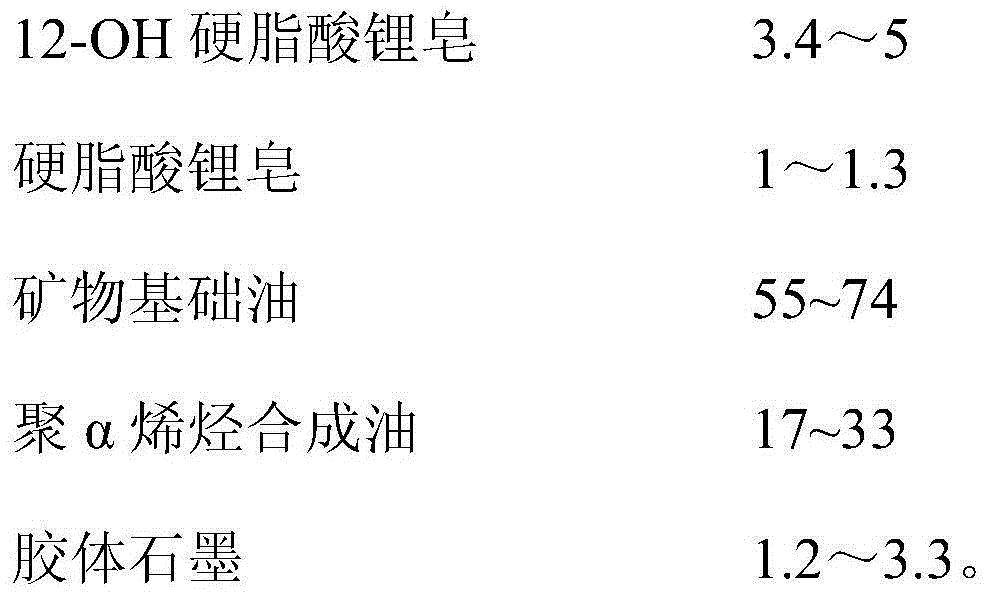

[0038] A steel wire rope grease composition for low temperature environment, characterized in that the composition comprises by weight parts:

[0039]

[0040]

[0041] Said polyalphaolefin synthetic oil has a kinematic viscosity of 8-11mm at 100°C 2 / s.

[0042] The particle size of the colloidal graphite is less than 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com