Concrete impermeable sealant

A sealant and concrete technology, applied in the field of oil, grease or wax, can solve the problems of paraffin and rosin pungent taste, difficulty in uniform application, loss of impervious seal, etc., to achieve obvious economic and social benefits, and good sealing ,Easy to apply evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

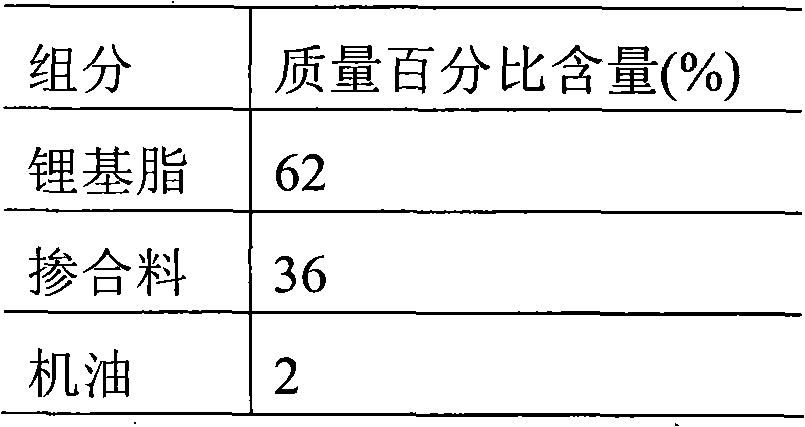

[0010] A concrete anti-seepage sealant, which is uniformly mixed with lithium base grease, admixtures and engine oil, and the mass percentage concentration of each component is:

[0011]

[0012] in:

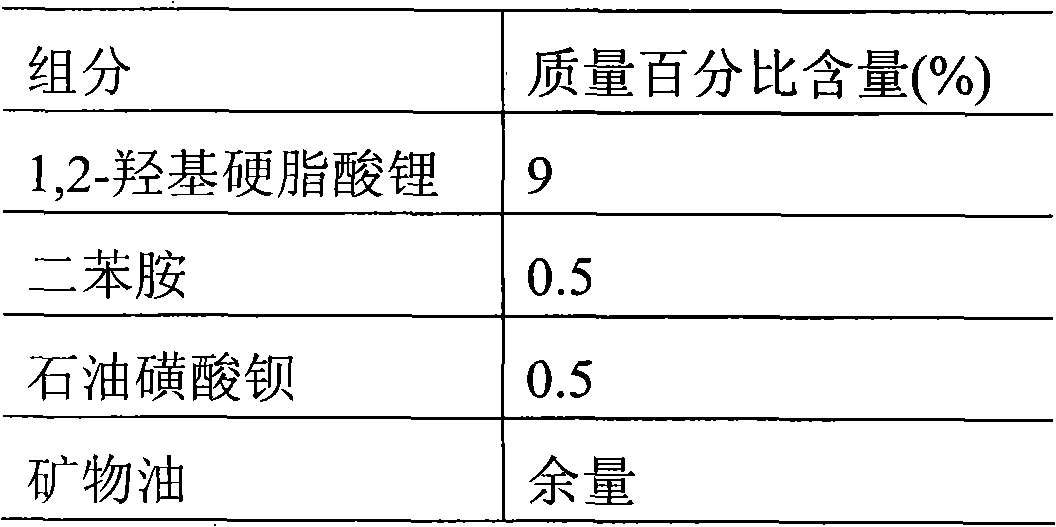

[0013] Lithium-based grease is made by mixing and thickening mineral oil, 1,2-hydroxystearyl lithium, diphenylamine and barium petroleum sulfonate. The penetration of lithium-based grease is 35.5mm-38.5mm. The components of lithium-based grease The mass percent concentration of is:

[0014]

[0015] The admixture is selected from fly ash, coal gangue powder or cement powder, and the particle diameter of the powder is less than 0.9mm.

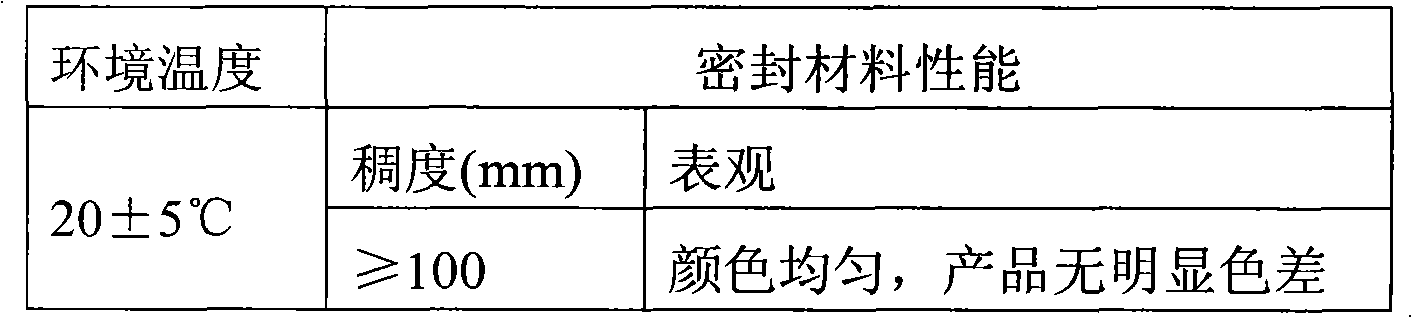

[0016] The performance requirements that this embodiment should meet are shown in the following table:

[0017]

[0018] This embodiment is suitable for use when the ambient temperature is lower than 5°C.

Embodiment 2

[0020] A concrete anti-seepage sealant, which is uniformly mixed with lithium base grease, admixtures and engine oil, and the mass percentage concentration of each component is:

[0021]

[0022] in:

[0023] Lithium-based grease is mixed and thickened by mineral oil, 1,2-hydroxystearyl lithium, diphenylamine and barium petroleum sulfonate. The penetration of lithium-based grease is 31mm-34mm. The mass of each component of lithium-based grease The percentage concentration is:

[0024]

[0025] The admixture is selected from fly ash, coal gangue powder or cement powder, and the particle diameter of the powder is less than 0.9mm.

[0026] The performance requirements that this embodiment should meet are shown in the following table:

[0027]

[0028] This embodiment is suitable for use when the ambient temperature is not lower than 5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com