Thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and production method thereof

A ceramic plate and waste technology, which is applied in the field of lightweight thermal insulation decorative ceramic plates, can solve the problems of blank utilization of expanded perlite, long firing cycle, and low utilization rate of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

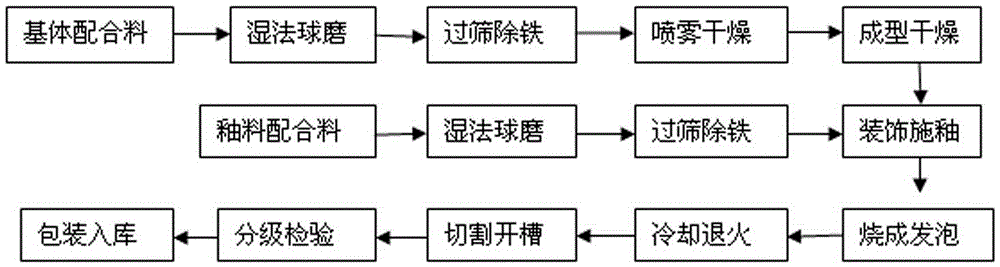

[0034] A kind of preparation method of the heat-preserving decorative ceramic board that comprehensively utilizes perlite waste to produce, concrete steps are as follows, as figure 2 Shown:

[0035] Step 1. Preparation of the base body of the thermal insulation and decorative ceramic plate:

[0036] Combine industrial waste including perlite micropowder and expanded perlite micropowder with Guangdong black mud, limestone, fluorite, bentonite, foaming aid black silicon carbide, alkali water additive nonahydrate sodium metasilicate, humic acid Sodium, sodium tripolyphosphate, and solvent water are put into the ceramic ball mill according to the mass percentage of the raw materials, and the ball mill is prepared into a ceramic slurry. The slurry is sieved, aged, and spray-dried to prepare a powder. Body;

[0037] Step 2. Preparation of the decorative glaze layer of the thermal insulation decorative ceramic plate:

[0038] Put expanded perlite micropowder, low-temperature frit...

Embodiment 1

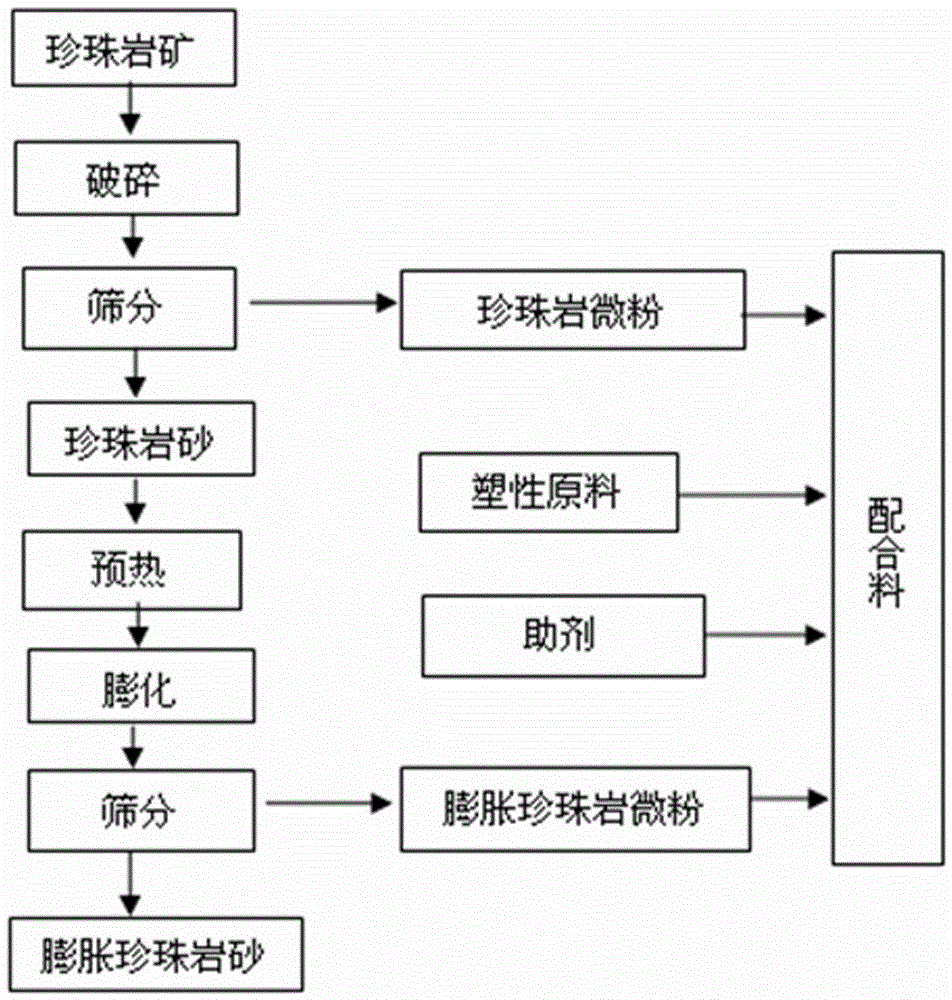

[0042] Such as figure 1 Shown, mixed by 66wt% perlite micropowder, 20wt% expanded perlite micropowder, 10wt% bentonite, 2wt% limestone, 2wt% fluorite powder, 0.8wt% sodium metasilicate nonahydrate, 0.8wt% 101.8wt% mineral raw materials composed of black silicon carbide and 0.2wt% sodium humate are put into a medium-aluminum lined ball mill and 55wt% of water wet ball mill is added; wherein, the fineness of the mud is controlled at 10,000-hole sieve The range is 0.6~1%, the mud flow rate is controlled in the coating four viscosity range is 25~45s; the powder particle gradation is controlled to be less than 2% on the 30 mesh sieve, more than 65% on the 60 mesh sieve under the 30 mesh sieve, and more than 65% on the 60 mesh sieve. The upper 80-mesh sieve is less than 30%, and the lower 80-mesh sieve is less than 5%; the moisture content of the powder is 6.5-7.5%; the dry strength of the green body is controlled at 0.95-1.2MPa. According to the above process system, after ball mi...

Embodiment 2

[0044] Such as figure 1 As shown, mix 88wt% perlite powder, 8wt% bentonite, 2wt% limestone, 2wt% fluorite powder, 0.8wt% black silicon carbide, 1wt% sodium metasilicate, 0.6wt% fluorite , 0.1wt% green body strengthening agent, 0.2wt% sodium humate, 0.1wt% sodium tripolyphosphate composed of 102.8wt% mineral raw materials were put into the aluminum lined ball mill and added 55wt% water wet method ball milling. Among them, the fineness of the mud is controlled in the range of 0.6~1% of the sieve residue of the ten-thousand-hole sieve, the flow rate of the mud is controlled in the Tu-4 viscosity range of 25~45s; More than 65% under the 60-mesh sieve, less than 30% under the 80-mesh sieve under the 60-mesh sieve, and less than 5% under the 80-mesh sieve; the moisture range of the powder is 6.5~7.5%; the dry strength of the green body is controlled at 0.95~1.2MPa . According to the above process system, the water absorption rate is 0.25%, and the volume is obtained after raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com