Preparation method for purple archaistic ceramic pigment

A technology for purple pigments and ceramics, applied in the field of preparation of antique ceramic purple pigments, can solve the problems of low product quality, harsh reaction conditions, high environmental hazards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Design Chinese violet pigment components according to the molar ratio of n(Ba):n(Cu):n(Si)=1:1:2. First weigh a certain amount of Na 2 SiO 3 9H 2 O, use deionized water to prepare an aqueous solution with a concentration of 0.60 mol / L. Then weigh barium nitrate Ba(NO) according to the designed molar ratio 3 ) 2 and copper nitrate Cu(NO 3 ) 2 ·3H 2 O chemical reagents, and dissolved with appropriate amount of deionized water.

[0042] (2) Put the sodium silicate aqueous solution in a constant temperature magnetic stirrer, continuously stir at 45°C and add the copper nitrate solution dropwise, and continue to add the barium nitrate solution dropwise after 10 minutes, and continue to stir at a constant temperature for 30 minutes to obtain silicic acid Copper-barium copolymer precipitate suspension.

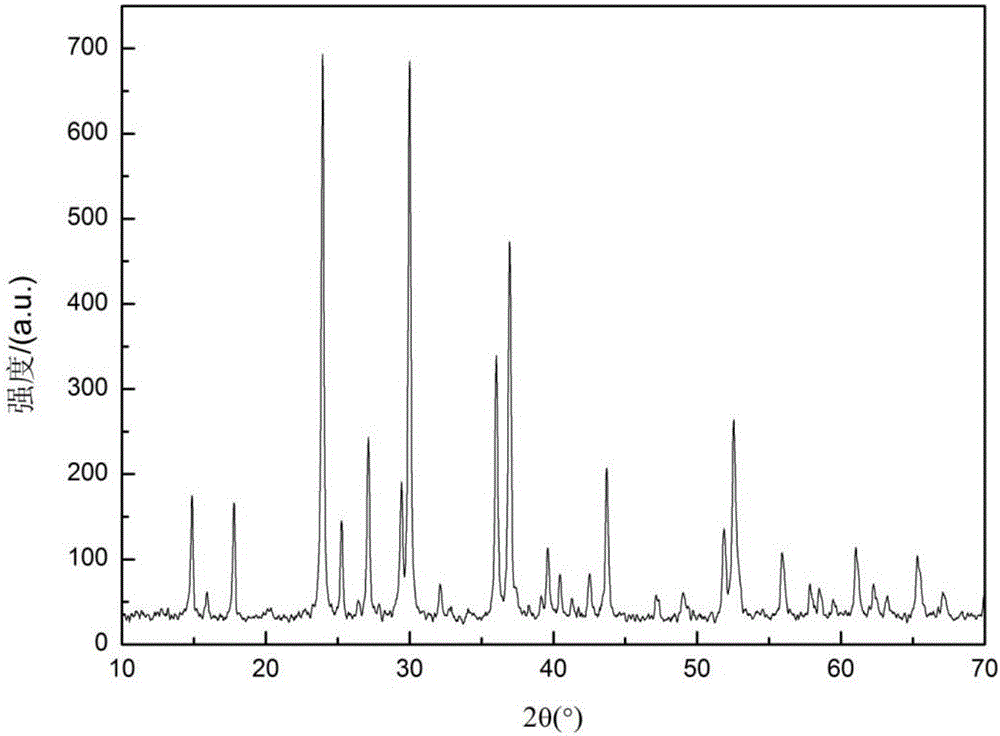

[0043] (3) The resulting copolymerized precipitate suspension was washed and suction-filtered three times, and dried in an oven at 90°C. The obtained powder is t...

Embodiment 2

[0046] (1) Design Chinese violet pigment components according to the molar ratio of n(Ba):n(Cu):n(Si)=1:1:2. First weigh a certain amount of Na 2 SiO 3 9H 2 O, use deionized water to prepare an aqueous solution with a concentration of 0.50 mol / L. Then weigh barium nitrate Ba(NO) according to the designed molar ratio 3 ) 2 and copper nitrate Cu(NO 3 ) 2 ·3H 2 O chemical reagents, and dissolved with appropriate amount of deionized water.

[0047] (2) Put the sodium silicate aqueous solution in a constant temperature magnetic stirrer, continuously stir at 50°C, and add the copper nitrate solution dropwise, after 5 minutes, continue to add the barium nitrate solution dropwise, and continue to stir at a constant temperature for 20 minutes to obtain silicic acid Copper-barium copolymer precipitate suspension.

[0048] (3) The resulting copolymerized precipitate suspension was washed and suction-filtered three times, and dried in an oven at 80°C. Then grind and compact the ...

Embodiment 3

[0051] (1) Design Chinese violet pigment components according to the molar ratio of n(Ba):n(Cu):n(Si)=1:1:2. First weigh a certain amount of Na 2 SiO 3 9H 2 O, use deionized water to prepare an aqueous solution with a concentration of 0.55mol / L. Then weigh barium nitrate Ba(NO) according to the designed molar ratio 3 ) 2 and copper nitrate Cu(NO 3 ) 2 ·3H 2 O chemical reagents, and dissolved with appropriate amount of deionized water.

[0052] (2) Put the sodium silicate aqueous solution in a constant temperature magnetic stirrer, continuously stir at 40°C, and add the copper nitrate solution dropwise, after 8 minutes, continue to add the barium nitrate solution dropwise, and continue to stir at a constant temperature for 20 minutes to obtain silicic acid Copper-barium copolymer precipitate suspension.

[0053] (3) The resulting copolymerized precipitate suspension was washed twice with suction and filtered, and dried in an oven at 90°C. The obtained powder is then g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com