Adhesive composition, adhesive film, method for preparing the adhesive film and display part

An adhesive film and adhesive technology, applied in the directions of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve problems such as deterioration of touch panel characteristics, achieve minimized corrosion, easy to coat The effect of cloth, excellent durability and cuttability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

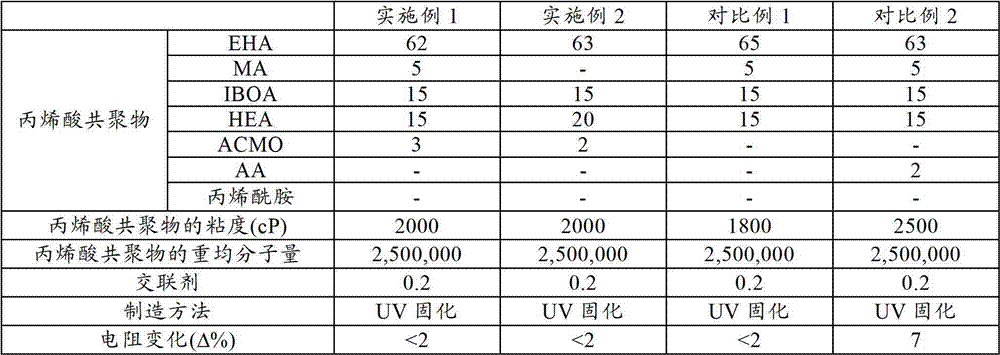

Embodiment 1

[0059] In a glass container, 62 parts by weight of ethylhexyl acrylate, 5 parts by weight of methyl acrylate, 15 parts by weight of isobornyl acrylate, 15 parts by weight of hydroxyethyl acrylate, 3 parts by weight of acryloyl morpholine and 2,2-dimethoxy-2-phenylacetophenone ( 651, Ciba Japan K.K.) mixed. The mixture was polymerized by ultraviolet irradiation using a low-pressure lamp (Sylvania BL Lamp), thereby obtaining a (meth)acrylic copolymer having a viscosity of 2,000 cP at 25°C. A (meth)acrylic acid copolymer was mixed with 0.2 parts by weight of 1,6-hexanediol diacrylate (HDDA) as a crosslinking agent and 0.3 parts by weight of a polymerization initiator ( 651) mixing, thereby preparing the adhesive composition. The adhesive composition was coated onto a polyester film having a thickness of 50 μm as a release film to form an adhesive film having a thickness of 175 μm. The opposite surface of the release film was irradiated for 6 minutes using a low-pressure lamp...

Embodiment 2

[0061] Adhesive film was prepared in the same manner as in Example 1, except that instead of adding 5 parts by weight of methyl acrylate, 63 parts by weight of ethylhexyl acrylate, 15 parts by weight of isobornyl acrylate, 20 parts by weight of of hydroxyethyl acrylate and 2 parts by weight of acryloyl morpholine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com