Live component, image forming device using the live cornponent and imaging processing box

A technology of charged parts and images, applied in corona discharge devices, equipment for electric recording technology using charge patterns, thin material processing, etc., can solve problems such as uneven resistance, uneven charging, and difficulty in adjusting the resistance value of the rubber layer , to achieve the effect of suppressing the change of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

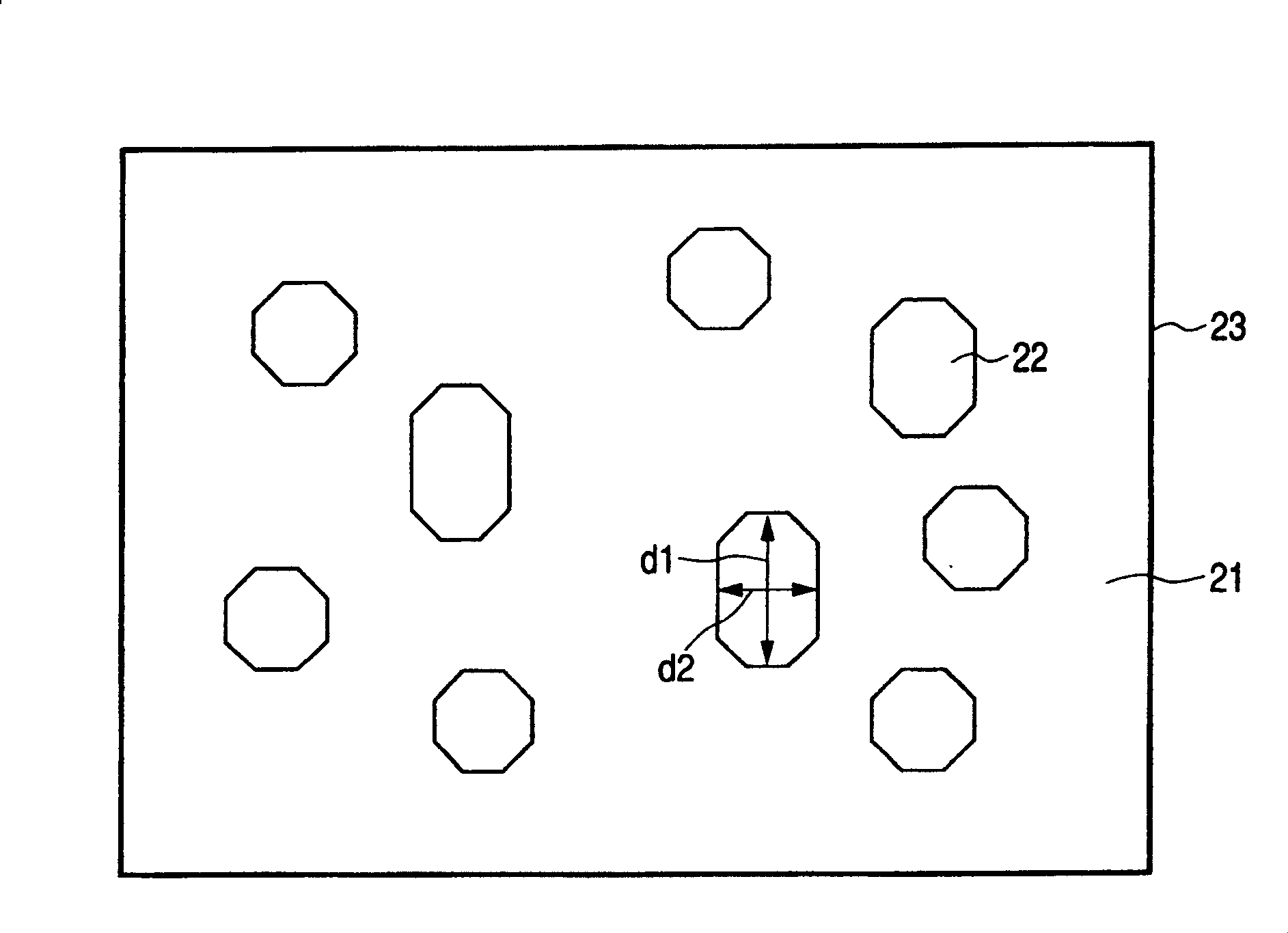

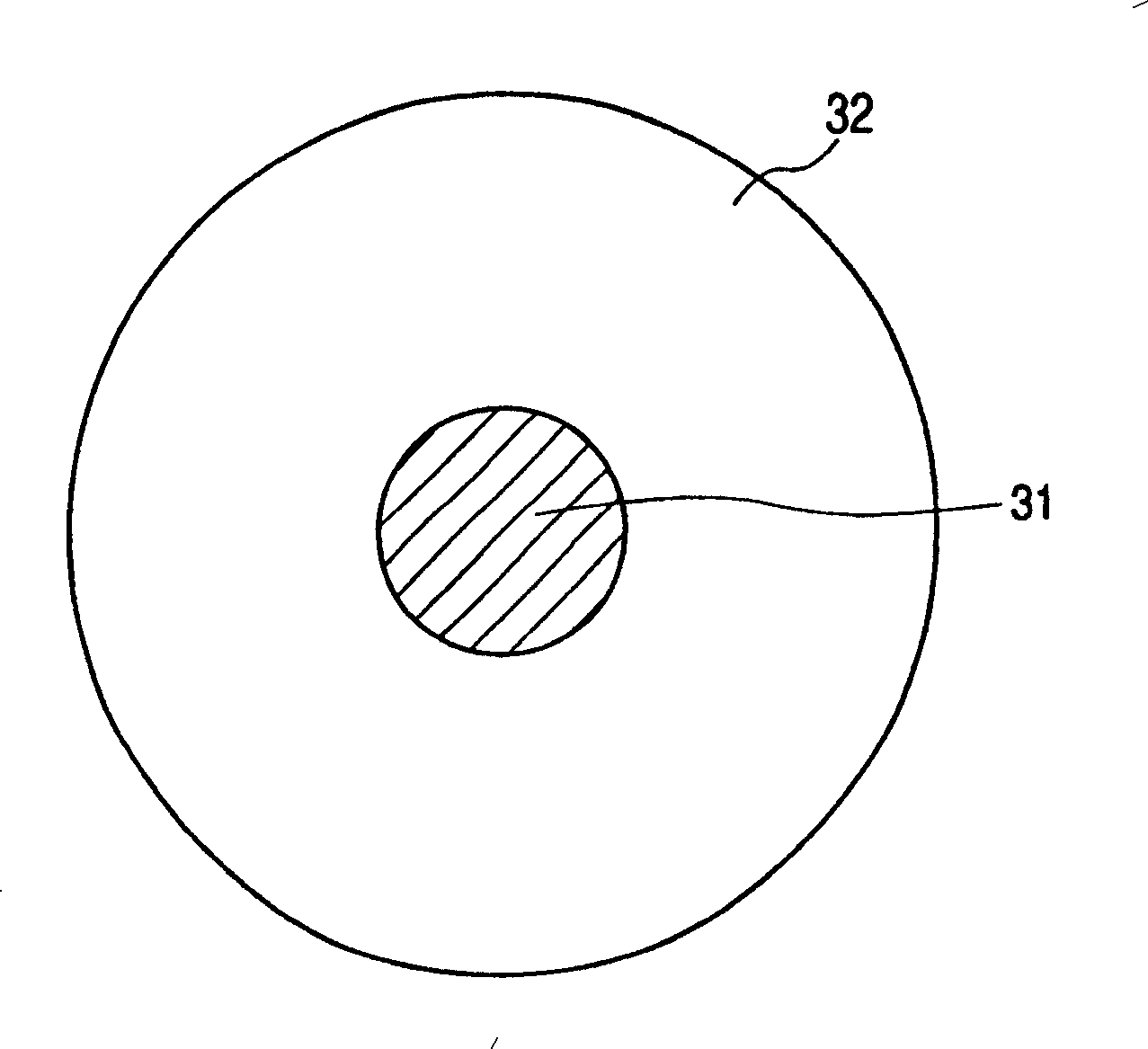

[0093] Follow the steps below to make a image 3 A transfer roller of the configuration shown.

[0094] A conductive cylindrical base material (metal core) 31 made of stainless steel with a diameter of 8 mm was prepared. In addition, the materials described below were mixed into a conductive elastic layer material with a pressure kneader.

[0095] · NBR (33.5% nitrile component) 76 parts

[0096] (Trade name: Nipol DN 214; manufactured by Japan Zeon Co., Ltd.)

[0097] ・Alkyl ether polymer (trade name: ZSN8030, manufactured by Japan Zeon Co., Ltd.) 20 parts

[0098] ・Epichlorohydrin rubber (trade name: EPICHLOMER H, manufactured by Daiso Co., Ltd.) 4 parts

[0100] ·Stearic acid 2 parts

[0101] · Hydrotalcite (hydrotalcite) 3 parts

[0102] · 20 parts of calcium carbonate

[0103] The NBR has the above formulas (A-1) and (A-2) as monomer units, and the copolymerization ratio (molar ratio) of (A-1) and (A-2) is 33.5:66.5. In addition, the...

Embodiment 2

[0124] A charging roller was obtained in the same manner as in Example 1, except that 64 parts of NBR, 6 parts of epichlorohydrin rubber, and 30 parts of alkyl ether polymer were used. The resistance value of the obtained charging roller was 2.80×10 7 Ω. In addition, its max. / min. value per revolution is 1.04. The hardness is 32.0°asker C.

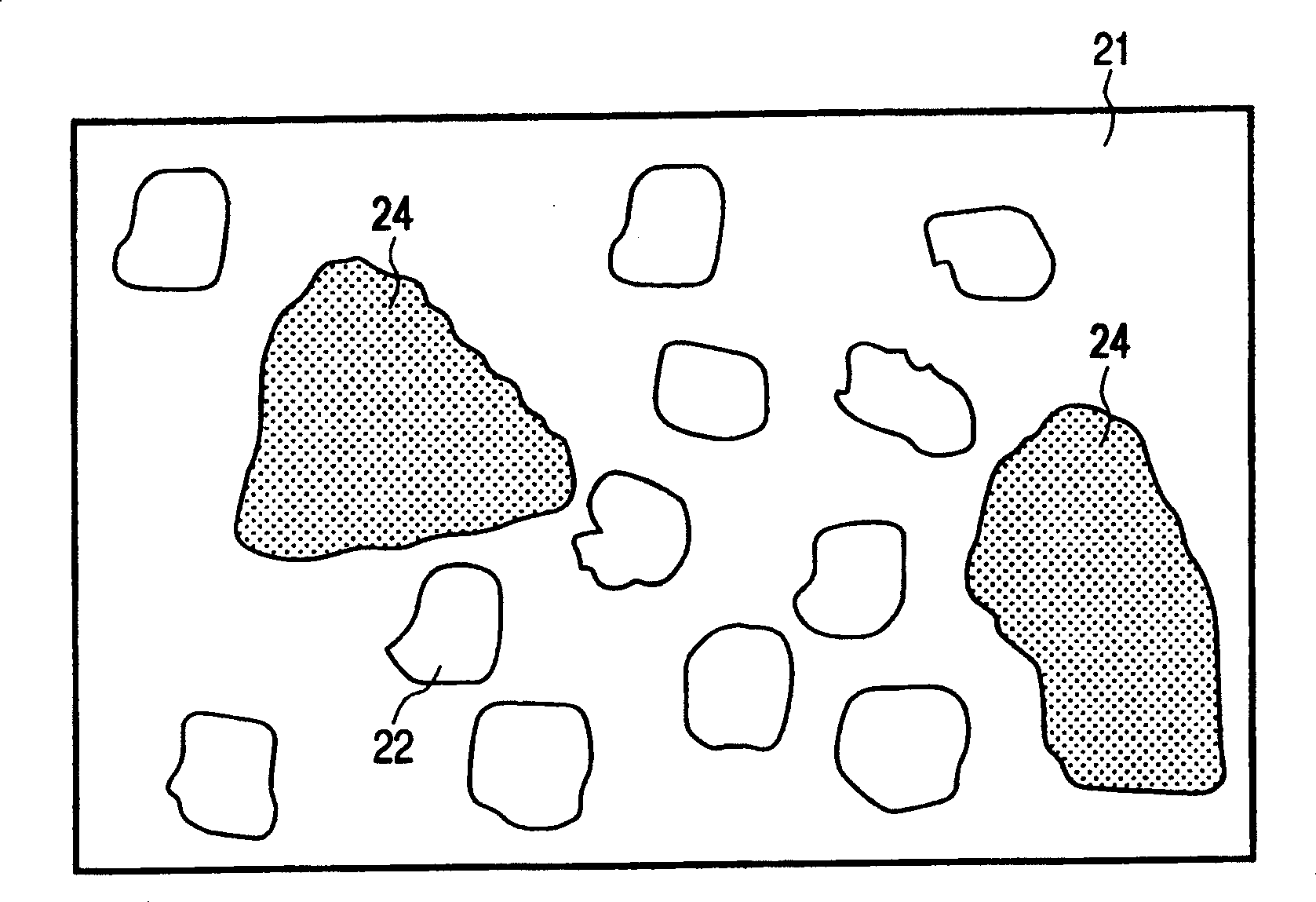

[0125] In addition, when the structure of the conductive elastic layer of this example was observed using a transmission electron microscope as in Example 1, it was found that it had a structure in which an island phase composed of an alkyl ether polymer was dispersed in a continuous phase composed of NBR. The average size of the island phases is 0.45 μm, and their average distance is 0.25 μm.

[0126] As in Example 1, the above charging roller was mounted on an electrophotographic device as a transfer roller, and the same evaluation as in Example 1 was performed using this electrophotographic device. As a result, a good image was obtai...

Embodiment 3

[0129] A charging roller was obtained in the same manner as in Example 1 except that 40 parts of NBR, 10 parts of epichlorohydrin rubber, and 50 parts of alkyl ether polymer were used. The resistance value of this charging roller is 7.81×10 6 Ω. In addition, its max. / min. value per revolution is 1.05. The hardness is 34.0°asker C.

[0130] As in Example 1, when the conductive elastic layer of this example was observed using a transmission electron microscope, it was found that NBR constituted a continuous phase and the alkyl ether polymer constituted an island phase. At this time, the average size of the island phase was 0.82 μm, and the average distance thereof was 0.32 μm.

[0131] In the same manner as in Example 1, the above-mentioned charging roller was mounted on an electrophotographic device as a transfer roller. With this electrophotographic device, when a solid black image was evaluated using a dry paper, a good image was obtained. Furthermore, when 500,000 sheets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com