Foaming type kitchen heavy oil removal agent and preparation method thereof

A foam type, heavy oil technology, applied in the field of cleaning agents, can solve the problems of poor removal effect of heavy dirt, not suitable for kitchen environment, explosive and other problems, achieve excellent foaming performance and adhesion, efficient oil cleaning power, and improve the removal The effect of detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

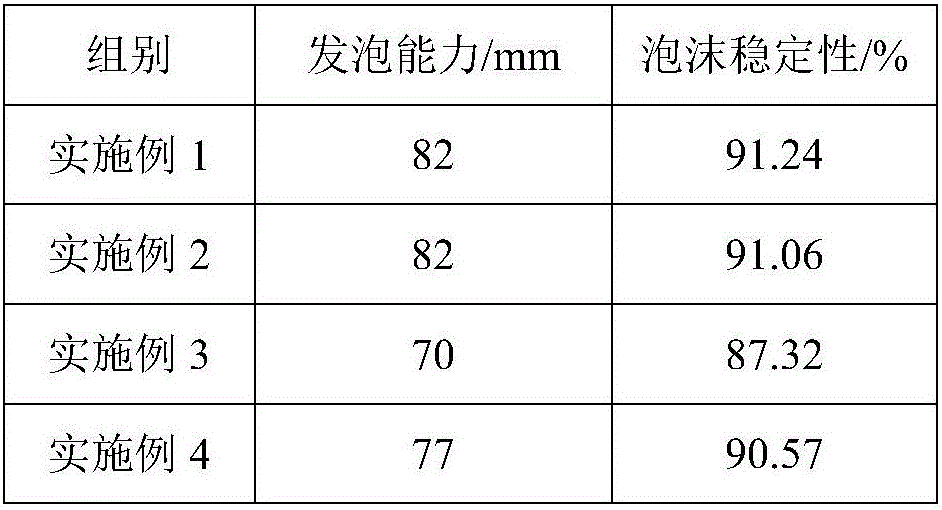

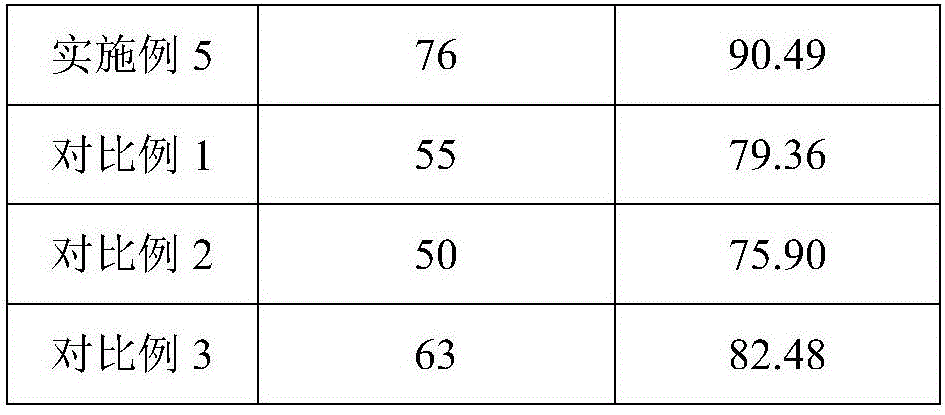

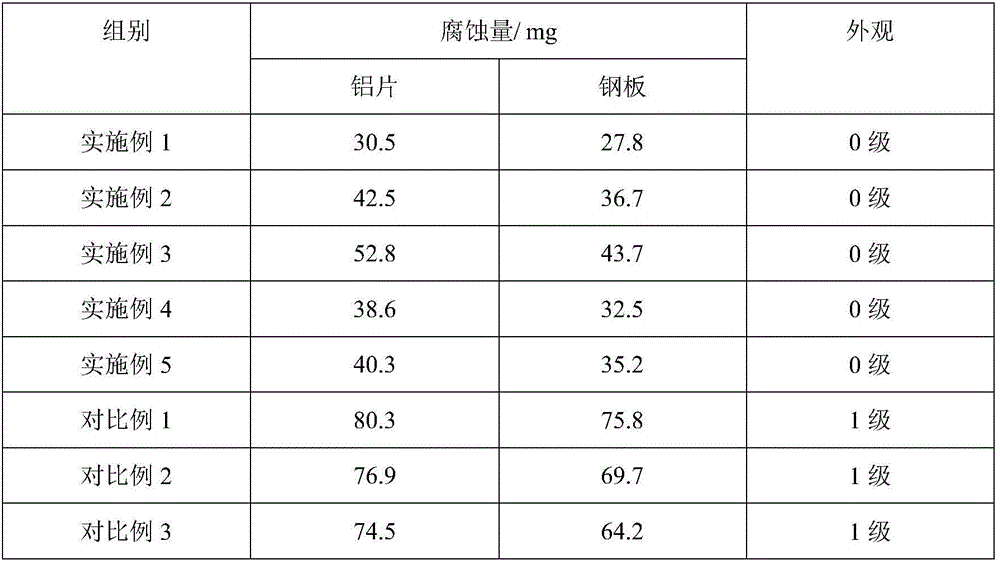

Examples

Embodiment 1

[0029] The foam-type kitchen degreasing agent of the embodiment of the present invention 1 is made up of the following preparation raw materials by weight percentage:

[0030] Sodium hydroxide 1.5%, sodium carbonate 1.5%, fatty alcohol polyoxyethylene ether sulfate sodium 2.0%, dodecylbenzene sulfonic acid 1.8%, triethanolamine 2.5%, sodium metasilicate nonahydrate 1.5%, fatty alcohol polymer Oxyethylene (7) ether 2.0%, sodium tripolyphosphate 0.8%, essence 0.4%, citric acid 1.0%, dimethylisothiazolinone 0.3%, and the balance is deionized water.

[0031] Preparation:

[0032] (1) adding fatty alcohol polyoxyethylene ether sulfate sodium, dodecylbenzene sulfonic acid, fatty alcohol polyoxyethylene (7) ether into deionized water, and stirring until the system becomes a uniform transparent liquid;

[0033] (2) adding sodium hydroxide, sodium carbonate, triethanolamine, sodium metasilicate nonahydrate, sodium tripolyphosphate while stirring, until the material is completely disso...

Embodiment 2

[0036] The foam-type kitchen degreasing agent of the embodiment of the present invention 2 is made up of the following preparation raw materials by weight percentage:

[0037] Sodium hydroxide 3.0%, sodium carbonate 0.5%, fatty alcohol polyoxyethylene ether sulfate sodium 3.0%, dodecylbenzene sulfonic acid 3.0%, triethanolamine 3.0%, sodium metasilicate nonahydrate 3.0%, fatty alcohol polymer Oxyethylene (7) ether 3.0%, sodium tripolyphosphate 2%, essence 0.1%, citric acid 3%, dimethylisothiazolinone 0.1%, and the balance is deionized water.

[0038] Refer to Example 1 for the preparation method.

Embodiment 3

[0040] The foam-type kitchen degreasing agent of the embodiment of the present invention 3 is made up of the following preparation raw materials by weight percentage:

[0041] Sodium hydroxide 0.5%, sodium carbonate 2.0%, fatty alcohol polyoxyethylene ether sulfate sodium 0.5%, dodecylbenzene sulfonic acid 0.5%, triethanolamine 3.0%, sodium metasilicate nonahydrate 0.5%, fatty alcohol polymer Oxyethylene (7) ether 3.0%, sodium tripolyphosphate 5.0%, essence 0.5%, citric acid 0.4%, dimethylisothiazolinone 0.3%, and the balance is deionized water.

[0042] Refer to Example 1 for the preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com