Well cementation working solution prepared from red mud, slag and waste drilling fluids

A technology of waste drilling fluid and working fluid, which is applied in drilling composition, wellbore/well parts, earthwork drilling and production, etc., which can solve the problems of failure to realize red mud recycling, great environmental hazards, and red mud consumption Small and other problems, to improve rheology and sedimentation stability, solve environmental pollution problems, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

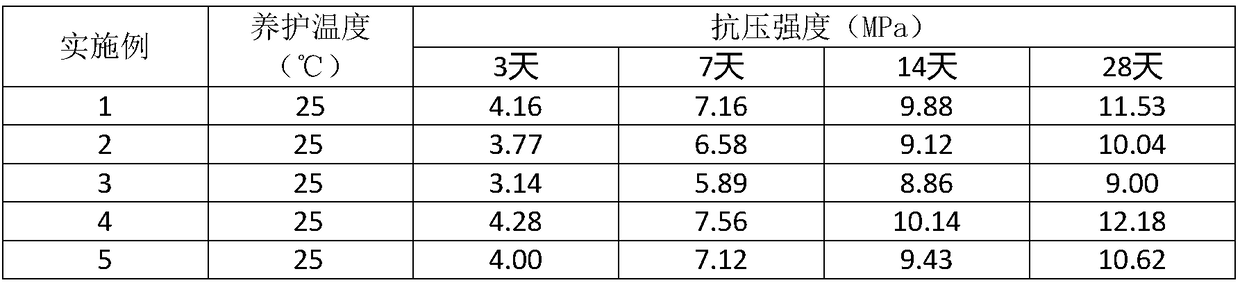

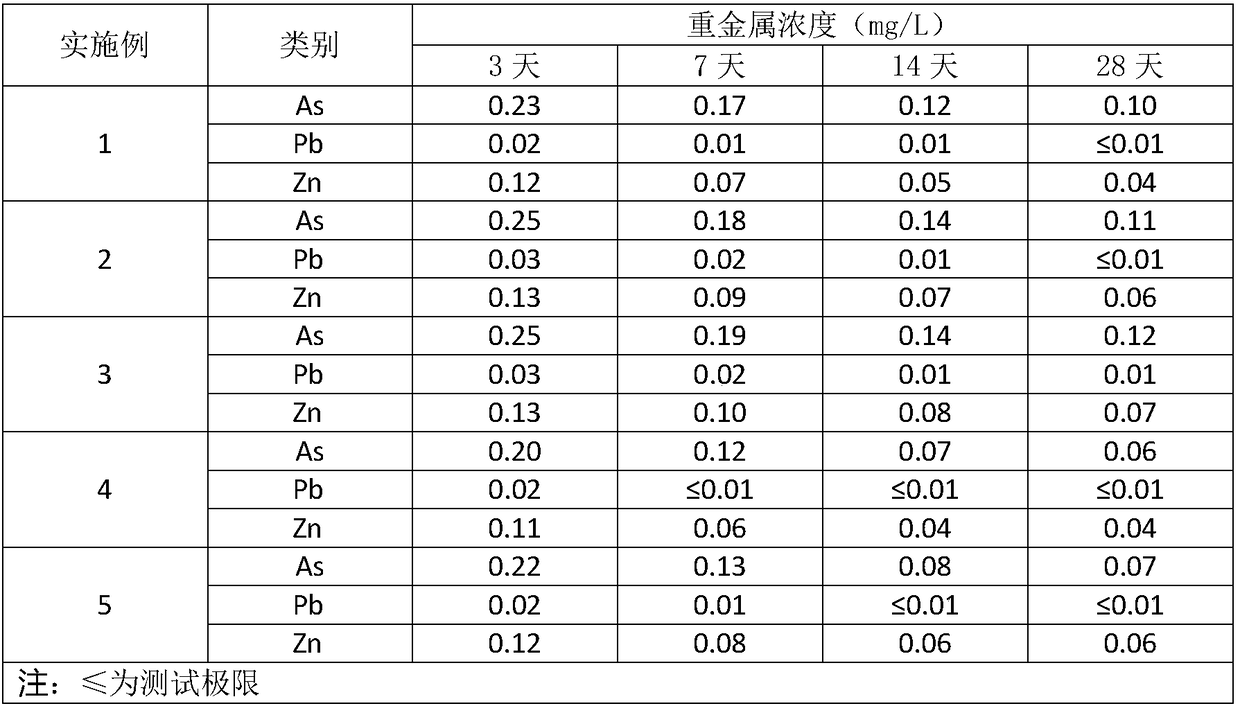

Embodiment 1

[0027] Recipe: waste drilling fluid (1.12g / cm 3 ) 100 parts, 90 parts of finely ground water-quenched blast furnace slag, 10 parts of red mud, 5 parts of sodium bentonite, 6 parts of sodium silicate nonahydrate, 1 part of sodium salicylate, and 0.5 parts of sodium lignosulfonate.

Embodiment 2

[0029] Recipe: waste drilling fluid (1.12g / cm 3 ) 100 parts, 80 parts of finely ground water-quenched blast furnace slag, 20 parts of red mud, 5.5 parts of carboxymethyl cellulose, 5.5 parts of sodium carbonate, 1.5 parts of potassium citrate, and 0.8 parts of sodium lignosulfonate.

Embodiment 3

[0031] Recipe: waste drilling fluid (1.12g / cm 3 ) 100 parts, finely ground water-quenched blast furnace slag 70 parts, red mud 30 parts, carboxymethyl cellulose 6 parts, sodium silicate nonahydrate 2 parts, sodium carbonate 3.8 parts, sodium salicylate 0.8 parts, potassium citrate 1 part, 1.2 parts of sodium lignosulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com