Fluorine titanium salt red-light material for white LED with two primary colors and preparation method of material

A dichroic and white light technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high concentration of etching solution, unfavorable large-scale industrial production, etc., and achieve the effect of high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

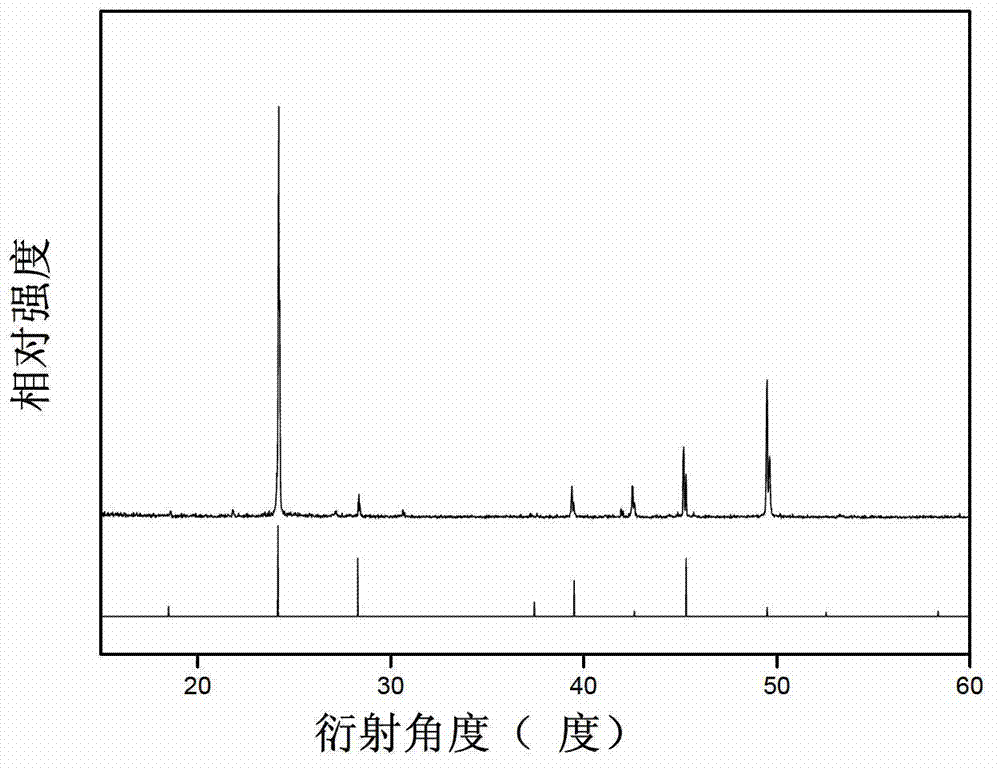

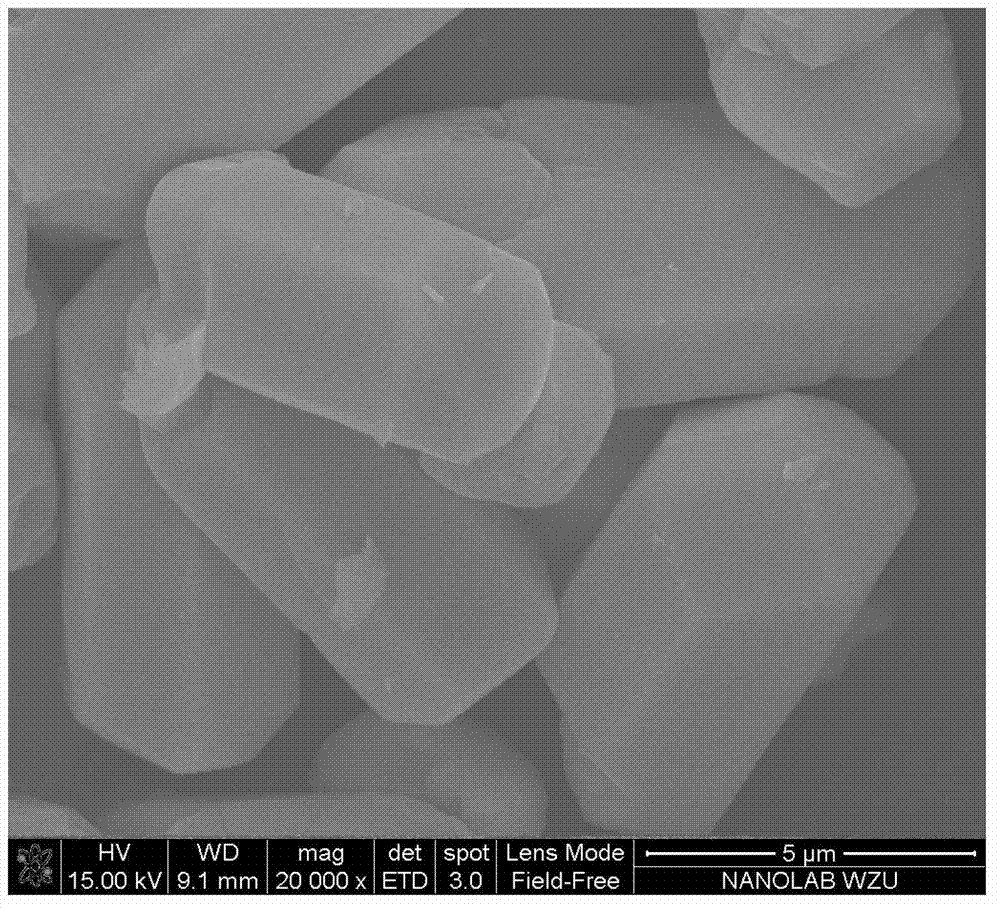

[0026] Add 0.8767g BaF 2 Solid, 1.7ml tetrabutyl titanate solution, 5ml KMnO with a concentration of 0.05mol / L 4 solution, 10ml of HF aqueous solution with a volume concentration of 40%, and then add 85ml of deionized water to keep the total volume of the reaction solution at 100ml. Stir magnetically for 20 minutes, put it into a stainless steel reaction kettle, put it in an oven at 120°C for 12 hours, take it out, and let it cool naturally. Suction filtration, washing with water, and natural drying to obtain a white powder. The product glows red under a UV light. Its XRD (detected by Bruker D8Advance X-ray diffractometer) is as follows figure 1 As shown, XRD shows that the product is pure BaTiF 6 Mutually. The scanning electron microscope is measured on Nova NanoSEM200, under the action of electron beam; as figure 2 As shown, magnified by 20,000 times, it is observed that the microscopic appearance of the product is fine granular, the size distribution is narrow, the d...

Embodiment 2

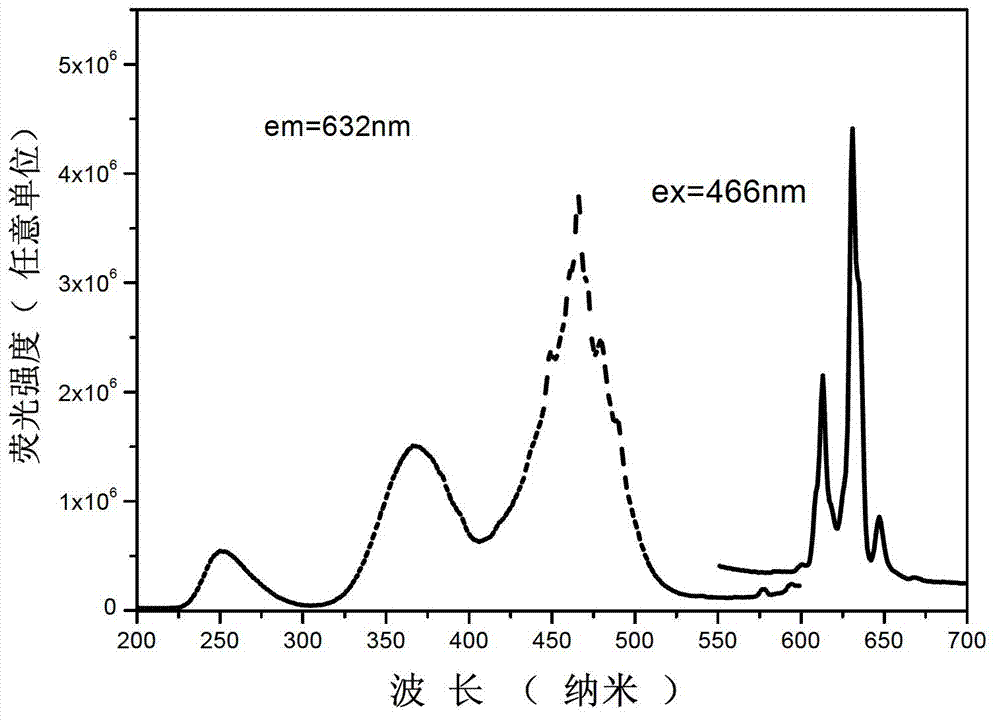

[0028] Add 0.8767g BaF 2 Solid, 1.7ml tetrabutyl titanate solution, 10ml KMnO with a concentration of 0.05mol / L 4 solution, 10ml of HF aqueous solution with a volume concentration of 40%, and then add 80ml of deionized water to keep the total volume of the reaction solution at 100ml. Stir magnetically for 20 minutes, put it into a stainless steel reaction kettle, put it in an oven at 120°C for 12 hours, take it out, and let it cool naturally. Suction filtration, washing with water, and natural drying to obtain a white powder. The product glows red under a UV light. Using a Fluoromax‐4 fluorescence spectrometer (HORIBA Jobin Yvon Inc.), the luminescent properties of the product were detected at room temperature, such as image 3 As shown, the excitation spectrum of the material consists of three broadband bands located at 250nm, 350nm, and 460nm, and its largest excitation band (460nm) completely matches the blue light emitted by the GaN blue chip. 650nm peak composition, t...

Embodiment 3

[0030] Add 0.8767g BaF 2 Solid, 1.7ml tetrabutyl titanate solution, 20ml KMnO with a concentration of 0.05mol / L 4 solution, 10ml of HF aqueous solution with a volume concentration of 40%, and 70ml of deionized water were added to keep the total volume of the reaction solution at 100ml. Stir magnetically for 20 minutes, put it into a stainless steel reaction kettle, put it in an oven at 120°C for 12 hours, take it out, and let it cool naturally. Suction filtration, washing with water, and natural drying to obtain a white powder. The product glows red under a UV light. The color coordinates of the material are located at: x=0.62, y=0.37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com