Modification method of polymer solid polyelectrolyte

A polyelectrolyte and polymer technology, which is applied in the direction of composite electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of affecting the performance of polymer electrolyte, poor film uniformity, and poor compatibility, so as to improve compatibility , reduce crystallinity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

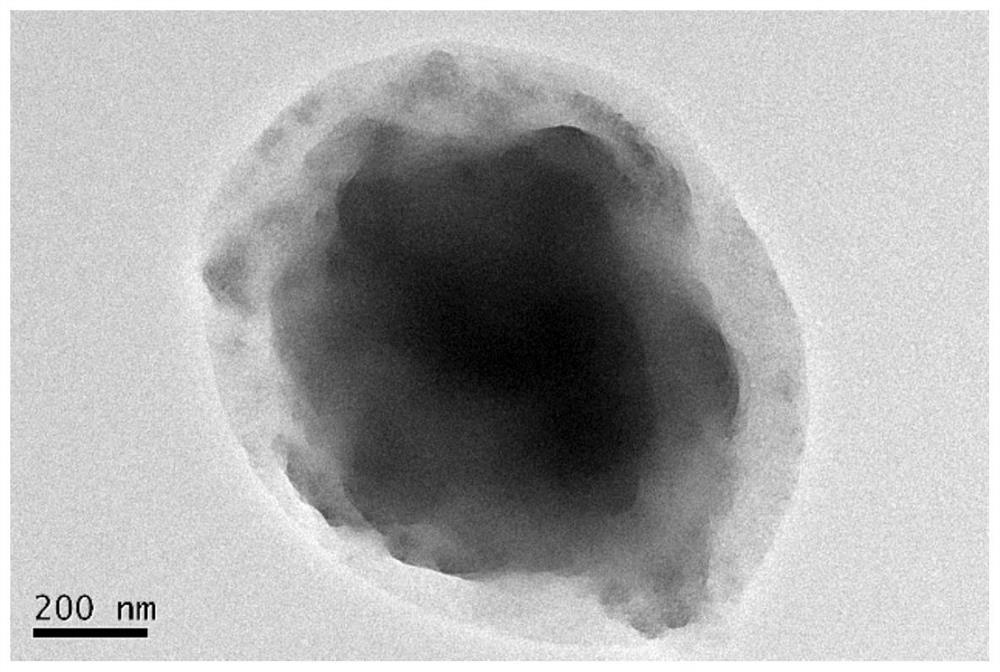

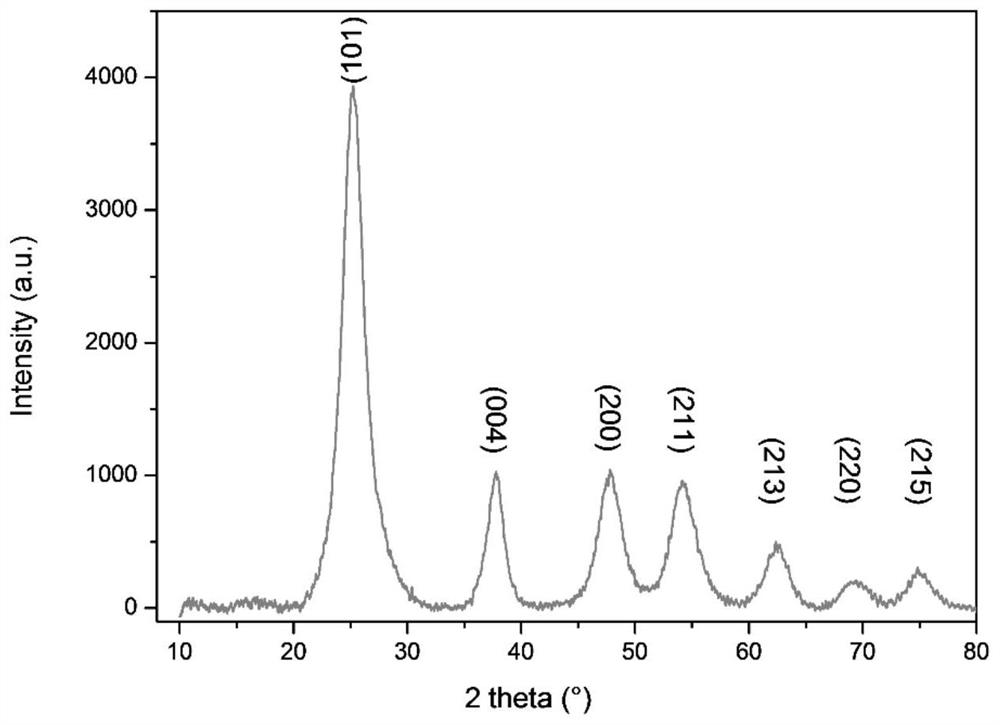

[0023] 1) PEO modified TiO 2 Nanoparticles (PEO-TiO 2 ) preparation

[0024] 20 parts by mass of titanium sulfate and 0.1 part by mass of polyethylene oxide (PEO) with a molecular weight of 400 were added to 50 mL of deionized water, and fully stirred to make them evenly mixed. Then, the mixed solution was added dropwise to 2.1wt% sodium hydroxide solution, and after a certain period of time, the precipitate was separated by centrifugation, and then it was placed in 0.2mol / L nitric acid solution and refluxed at a temperature of 80°C. After 1 h, the precipitate was separated by centrifugation, washed thoroughly with absolute ethanol, and dried thoroughly to obtain PEO-modified TiO 2 Nanoparticles (PEO-TiO 2 ).

[0025] 2) PEO-TiO 2 Preparation of Nanoparticles and Polyethylene Oxide-Polyphenylene Ether Copolymer Polyelectrolyte Composite Membrane

[0026] The polyethylene oxide-polyphenylene ether copolymer of 65 mass parts is dissolved in xylene, adds the PEO-TiO that 0....

Embodiment 2

[0029] 1) PEO modified TiO 2 Nanoparticles (PEO-TiO 2 ) preparation

[0030] 78 parts by mass of titanium sulfate and 20 parts by mass of PEO with a molecular weight of 1000 were added to 200 mL of deionized water, and fully stirred to make them evenly mixed. Then, add the mixed solution dropwise to 10.0wt% sodium hydroxide solution, after a certain period of time, centrifuge to separate the precipitate, then place it in 2.0mol / L nitric acid solution, and reflux at a temperature of 30°C After 3 h, the precipitate was separated by centrifugation, washed thoroughly with absolute ethanol, and dried thoroughly to obtain PEO-modified TiO 2 Nanoparticles (PEO-TiO 2 ).

[0031] 2) PEO-TiO 2 Preparation of Nanoparticles and Polyethylene Oxide-Polyphenylene Ether Copolymer Polyelectrolyte Composite Membrane

[0032] The polyethylene oxide-polyphenylene ether copolymer of 98 mass parts is dissolved in xylene, adds the PEO-TiO that 45 mass parts step 1) prepares 2 The nano-particl...

Embodiment 3

[0035] 1) PEO modified TiO 2 Nanoparticles (PEO-TiO 2 ) preparation

[0036] 55 parts by mass of titanium sulfate and 10 parts by mass of PEO with a molecular weight of 600 were added to 120 mL of deionized water, and fully stirred to make them evenly mixed. Then, add the mixed solution dropwise to 5.0wt% sodium hydroxide solution, after a certain period of time, centrifuge to separate the precipitate, then place it in a 1.0mol / L nitric acid solution, and reflux at a temperature of 50°C After 2 h, the precipitate was separated by centrifugation, washed thoroughly with absolute ethanol, and dried thoroughly to obtain PEO-modified TiO 2 Nanoparticles (PEO-TiO 2 ).

[0037] 2) PEO-TiO 2 Composite of Nanoparticles and Polyethylene Oxide-Polyphenylene Ether

[0038] The polyethylene oxide-polyphenylene ether copolymer of 80 mass parts is dissolved in xylene, adds the PEO-TiO that 30 mass parts step 1) prepares 2 Nanoparticles, fully stirred and dispersed evenly, then added b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com