Preparation method of yttrium aluminum oxygen composite oxide high K medium thin film transistor

A composite oxide and dielectric thin film technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of small forbidden band width, hinder the development of TFT, and small relative dielectric constant, and achieve dense and simplified thin films. The effect of simple process and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

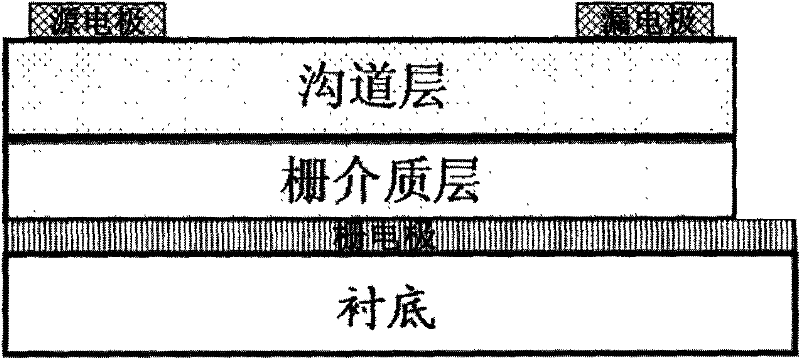

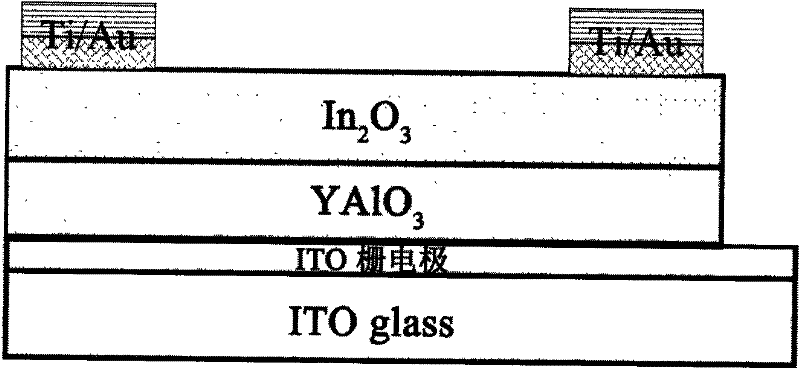

[0032] A YAlO with Bottom Gate Structure 3 A method for preparing a composite oxide high-K dielectric thin film transistor, the specific process is:

[0033] Step 1: Select commercially purchased ITO glass as the substrate, and leave a part of the edge of the glass as the gate electrode during preparation. The surface resistivity of the ITO glass is less than 15Ω / cm 2 ;

[0034] Step 2: Use magnetron sputtering equipment and metal yttrium target (Y) and aluminum target (Al), and react with oxygen at room temperature to sputter and deposit YAlO with a thickness of about 150nm 3 composite oxide dielectric film, then in O 2 Perform rapid annealing treatment under atmosphere, the annealing temperature is 200°C to 400°C, the heating rate is 20°C / min, and the annealing time is 10min;

[0035] Step 3: Using the method of magnetron sputtering, in O 2 Deposition of In at room temperature under atmosphere 2 o3 channel layer;

[0036] Step 4: Prepare Ti / Au source electrode and drai...

Embodiment 2

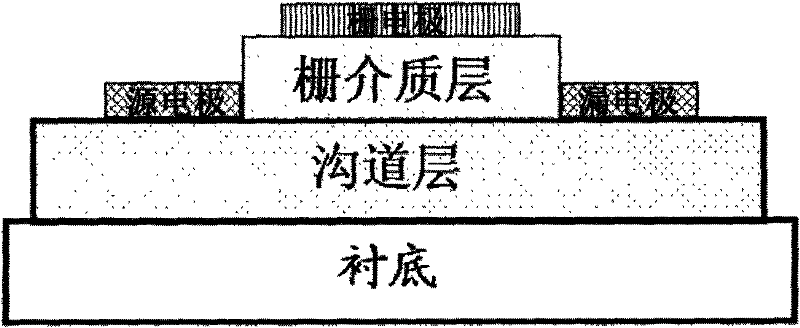

[0038] YAlO with a top-gate structure 3 A method for preparing a composite oxide high-K dielectric thin film transistor, the specific process is:

[0039] Step 1: Select commercially purchased ITO glass as the substrate, and the surface resistivity of the ITO glass is less than 15Ω / cm 2 ;

[0040] Step 2: Using the method of magnetron sputtering, in O 2 Deposition of In on ITO glass at room temperature under atmosphere 2 o 3 channel layer;

[0041] Step 3: Using magnetron sputtering equipment with metal yttrium target (Y) and aluminum target (Al), at room temperature on In 2 o 3 About 150nm YAlO was deposited on the channel layer by co-reactive sputtering with oxygen 3 composite oxide dielectric film, then in O 2 Perform rapid annealing treatment under atmosphere, the annealing temperature is 200°C to 400°C, the heating rate is 20°C / min, and the annealing time is 10min;

[0042] Step 4: Use electron beam evaporation equipment and Al mask to prepare Ti / Au source electr...

Embodiment 3

[0044] A YAlO with Bottom Gate Structure 3 A method for preparing a composite oxide high-K dielectric thin film transistor, the specific process is:

[0045] Step 1: Select commercially purchased ITO glass as the substrate, and leave a part of the edge of the glass as the gate electrode during preparation. The surface resistivity of the ITO glass is less than 15Ω / cm 2 ; and the substrate temperature is heated to 250°C.

[0046] Step 2: Use magnetron sputtering equipment, metal yttrium target (Y) and aluminum target (Al), and react with oxygen to sputter and deposit about 150nm YAlO under substrate temperature conditions 3 composite oxide dielectric film, then in O 2 Perform rapid annealing treatment under atmosphere, the annealing temperature is 200°C to 400°C, the heating rate is 20°C / min, and the annealing time is 10min;

[0047] Step 3: Using the method of magnetron sputtering, in O 2 Depositing In at atmospheric substrate temperature 2 o 3 channel layer;

[0048] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com