Lithium sodium fluosilicate red-light material for white-light LED (Light-Emitting Diode) and preparation method thereof

A lithium fluorosilicate and red light technology, applied in the field of luminescent materials, can solve the problem that the intensity of zero-photon rays needs to be further improved, and achieve the effects of reduced lattice symmetry, low cost, and increased intensity of zero-photon rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Accurately weigh 0.6 mol of solid lithium nitrate, 0.6 mol of solid sodium fluoride, 0.54 mol of solid silicon dioxide, and potassium fluoromanganate solid equivalent to 2 mol% of silicon dioxide according to the stoichiometric ratio, and put all the solids into a concentration of 50 ml % HF aqueous solution, stirred at room temperature for 5 hours, filtered with suction, and dried naturally.

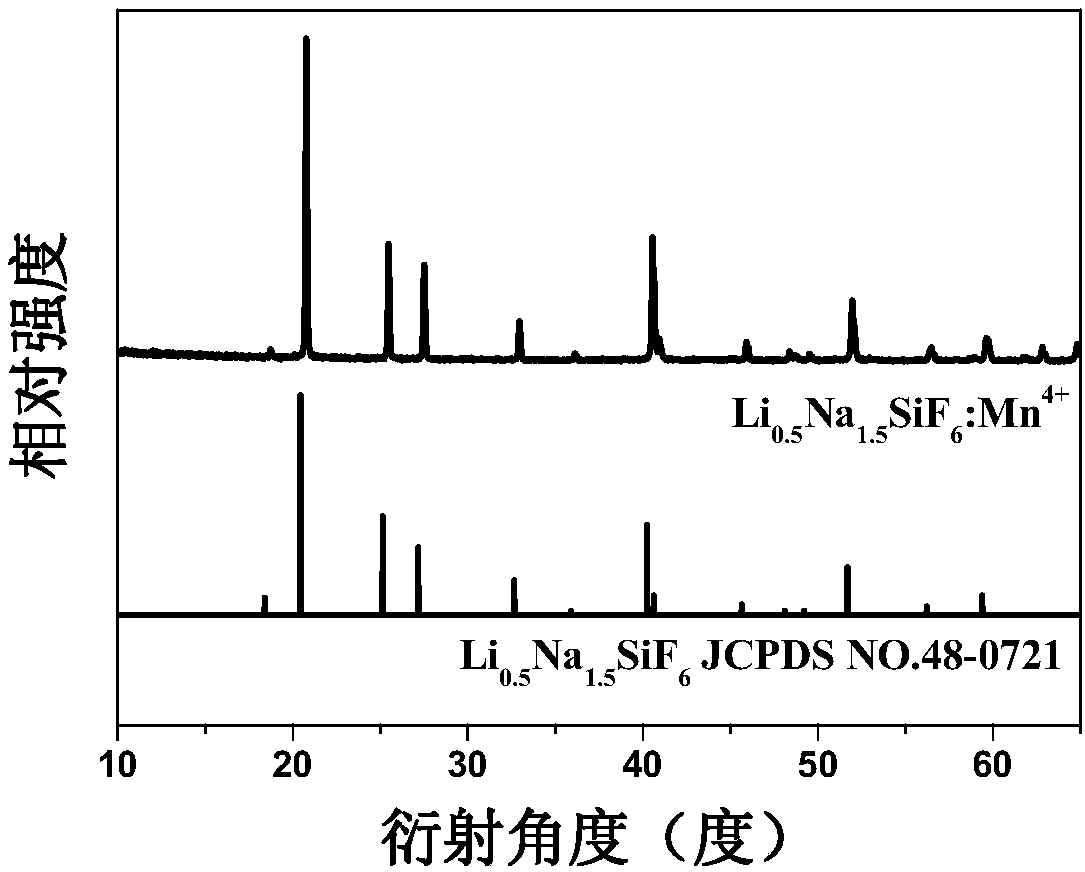

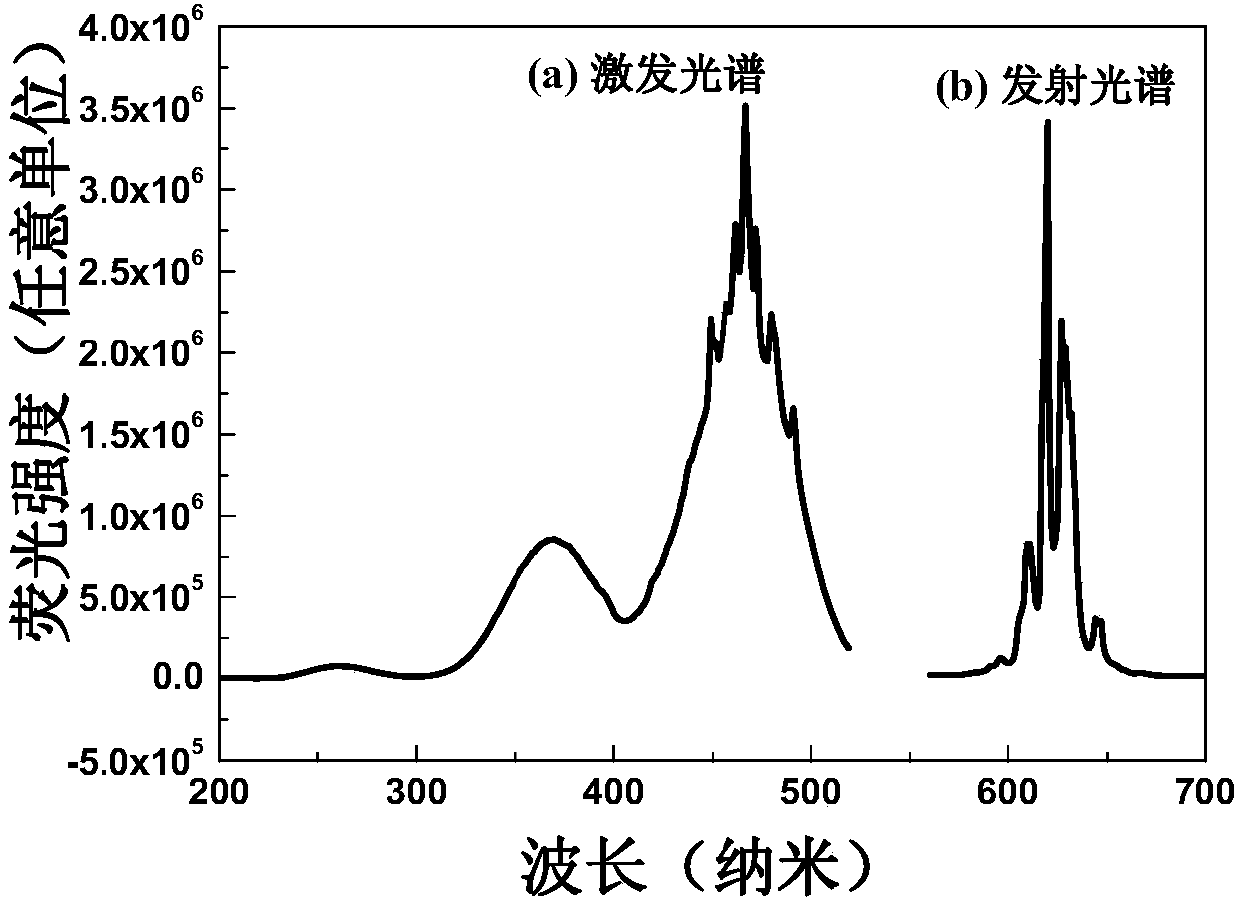

[0034] After testing, the product obtained in this embodiment is light yellow crystalline powder under natural light, and bright red light is found under ultraviolet light. Its XRD (Bruker D8Advance X-ray diffractometer detection) such as figure 1 As shown, XRD shows that the product is pure Li 0.5 Na 1.5 SiF 6 phase, an exact match to standard card 48‐0721. SEM is measured on Nova NanoSEM 200, under the action of electron beam, such as figure 2 As shown, magnified by 20,000 times, the microscopic appearance of the product is observed to be fine particles, with a diameter o...

Embodiment 2

[0040] Accurately weigh 0.6 mol of solid lithium nitrate, 0.6 mol of sodium fluoride, 0.54 mol of silicon dioxide, and potassium fluoromanganate equivalent to 0.25 mol% of silicon dioxide according to the stoichiometric ratio, and put all the solids into 50 ml of concentration of 20 wt .% HF aqueous solution, stirred at room temperature for 5 hours, filtered with suction, and dried naturally. The product glows red under a UV light. This product is a light yellow powder material, and its XRD pattern, scanning electron microscope, excitation spectrum and emission spectrum shape are basically the same as those of Example 1, while the intensity of excitation spectrum and emission spectrum is different. Fluoromax‐4 fluorescence spectrometer (HORIBA Jobin Yvon Inc .) Detection, the emission spectrum of the product of this embodiment is as Figure 4 As shown, the spectral shape and position are the same as in Example 1, but the intensity is weaker than that of Example 1 because the ...

Embodiment 3

[0042]Accurately weigh 0.6 mol of solid lithium nitrate, 0.6 mol of sodium fluoride, 0.54 mol of silicon dioxide, and potassium fluoromanganate equivalent to 0.5 mol% of silicon dioxide according to the stoichiometric ratio, and put all the solids into 50 ml of concentration of 20wt .% HF aqueous solution, stirred at room temperature for 5 hours, filtered with suction, and dried naturally. The product glows red under a UV light. This product is a light yellow powder material, and its XRD pattern, scanning electron microscope, excitation spectrum and emission spectrum shape are basically the same as those of Example 1, while the intensity of excitation spectrum and emission spectrum is different. Fluoromax‐4 fluorescence spectrometer (HORIBA Jobin Yvon Inc .) Detection, the emission spectrum of the product of this embodiment is as Figure 4 As shown, the spectral shape and position are the same as in Example 1, but the intensity is weaker than that of Example 1 because the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com