Preparation method for ultrafine In2Ge2O7(En) hybrid nano-wire, and nano-wire prepared by the same

A technology of nanowires and indium acetate, applied in the field of nanowires, can solve problems such as difficulty and limitations in the synthesis of ultra-fine nanowires, and achieve the effects of large application potential, mild preparation conditions, simple process and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 2mmol of indium acetate and 3mmol of germanium oxide into 15ml of a mixed solvent, and stir it magnetically for 0.5 to 1 hour to obtain a white suspension, wherein the mixed solvent is prepared by uniformly mixing ethylenediamine and water at a volume ratio of 14:1 have to;

[0028] (2) Pour the white suspension into a 25ml polytetrafluoroethylene-lined stainless steel autoclave, heat up to 180°C, react for 24 hours, and cool with the furnace after the reaction;

[0029] (3) The reaction product was centrifuged to obtain a solid powder, which was then washed with distilled water and ethanol in sequence, and then dried at 60°C for 8-12 hours to obtain ultrafine In 2 Ge 2 o 7 (En) Hybrid nanowires.

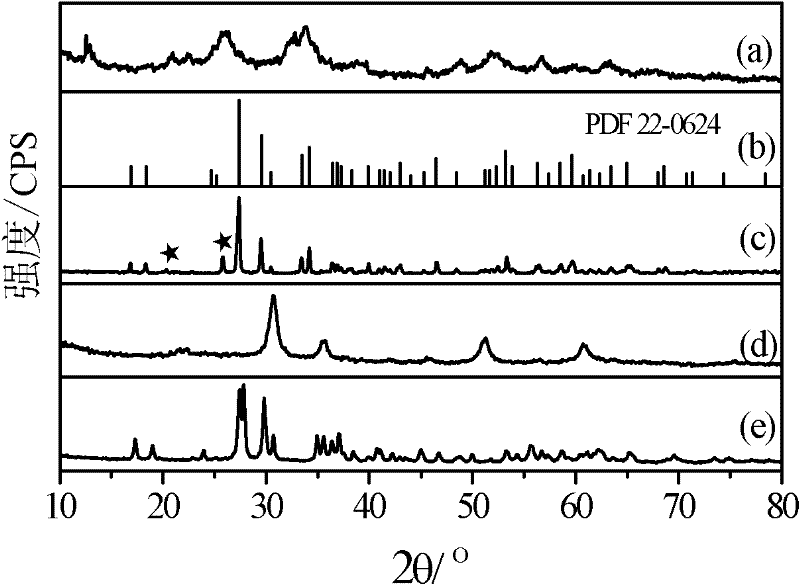

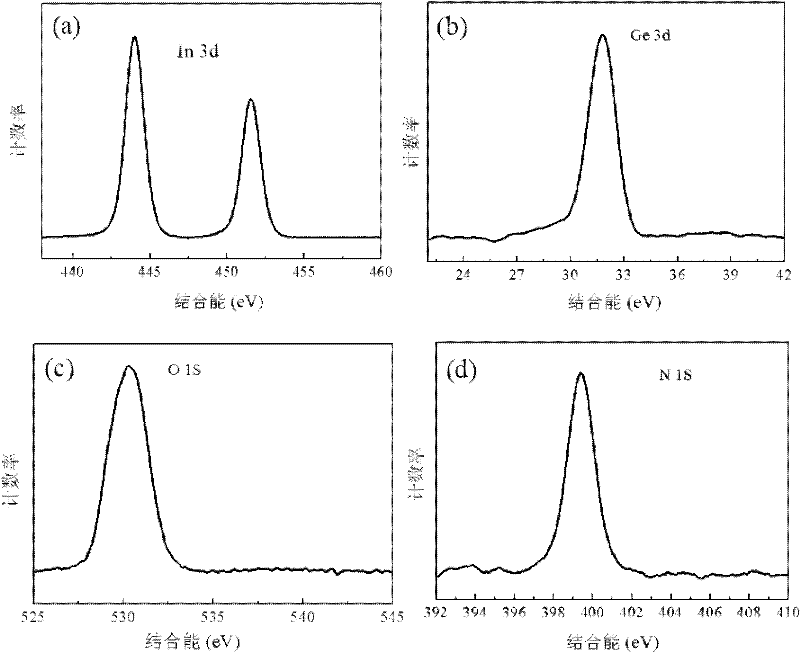

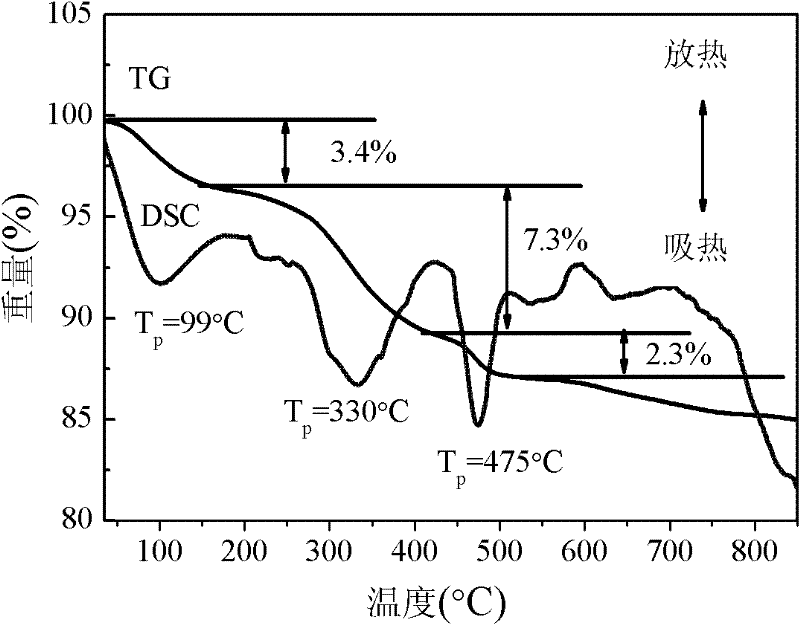

[0030] The products were analyzed by X-ray diffraction (XRD), photoelectron spectroscopy (XPS), thermogravimetry (TG), differential thermal analysis (DSC), fluorescence spectroscopy, scanning electron microscopy and transmission electron microscopy.

[0031] refer...

Embodiment 2

[0038] The steps are basically the same as in Example 1, except that the content of indium acetate is 0.2 mmol, the content of germanium oxide is 0.3 mmol, the volume ratio of ethylenediamine and water in the mixed solvent is 10:5, and the reaction time is 12 h.

[0039] The product that makes is basically consistent with embodiment 1, and its scanning electron microscope picture is as Figure 6 shown.

Embodiment 3

[0041] The steps are basically the same as in Example 1, except that the volume ratio of ethylenediamine and water in the mixed solvent is 10:5, the reaction temperature is 160° C., and the reaction time is 48 hours.

[0042] The product that makes is basically consistent with embodiment 1, and its scanning electron microscope picture is as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com