Preparation method of nano petaline Ni(OH)2

A petal-shaped and nano-technology, applied in the direction of nano-technology, nickel oxide/nickel hydroxide, etc., can solve the problems of no nano-petal-shaped nickel hydroxide reported in the literature, complicated preparation process, and large environmental load, etc., to achieve good crystal shape , Uniform grain size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Measure 0.02 mol / L NiSO 4 Put 150 mL of aqueous solution in a 500 mL beaker at room temperature, under stirring with a magnetic stirrer, slowly add 3 mL of 1.00 mol / L urea aqueous solution to the above NiSO 4 In the aqueous solution, continue to stir for 10 minutes, transfer the reaction mixture (the molar ratio of nickel to urea is 1:1) into a 200mL stainless steel reaction kettle lined with polytetrafluoroethylene, and put it in an electric thermostat at 170°C for 18 hours. Cool to room temperature. Filter, wash with deionized water until neutral, dry at 80°C to constant weight, and the petals become thinner to obtain nano-petal Ni(OH) 2 .

Embodiment 2

[0028] Measure 0.02 mol / L NiSO 4 Put 150 mL of aqueous solution in a 500 mL beaker at room temperature, under stirring with a magnetic stirrer, slowly add 6 mL of 1.00 mol / L aqueous urea solution to the above NiSO 4 In the aqueous solution, continue to stir for 10 minutes, transfer the reaction mixture into a 200mL stainless steel reaction kettle lined with polytetrafluoroethylene, put it in a 170°C electric thermostat for 2 hours, and then cool it down to room temperature naturally. Filter, wash with deionized water until neutral, dry at 80°C to constant weight, and the petals become thinner to obtain nano-petal Ni(OH) 2 .

[0029] Analysis example

[0030] 1. SEM analysis of prepared samples:

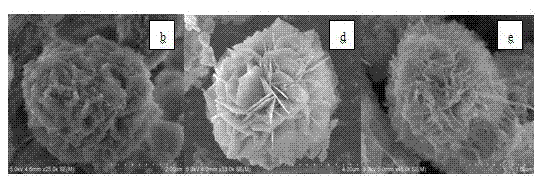

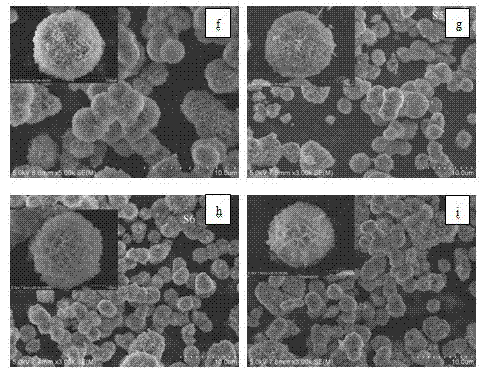

[0031] figure 1 Shown are the scanning electron micrographs of the prepared samples under different nickel: urea molar ratios. figure 1 where b, d, and e correspond to nickel:urea molar ratios of 1:2, 1:5, and 1:6, respectively.

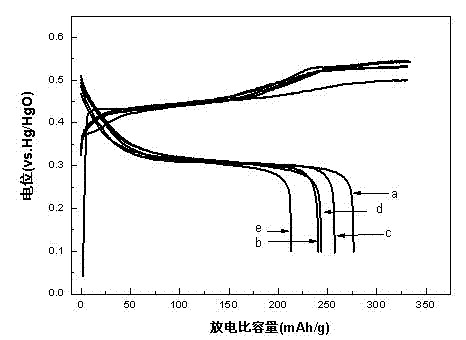

[0032] from figure 1 It can be seen that the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com