Preparation method and preparation device of bismuth telluride-based thermoelectric material

A thermoelectric material, bismuth telluride-based technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, etc., can solve the problems of expensive instruments, high energy consumption, complex process, etc., achieve short preparation time, The effect of low equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

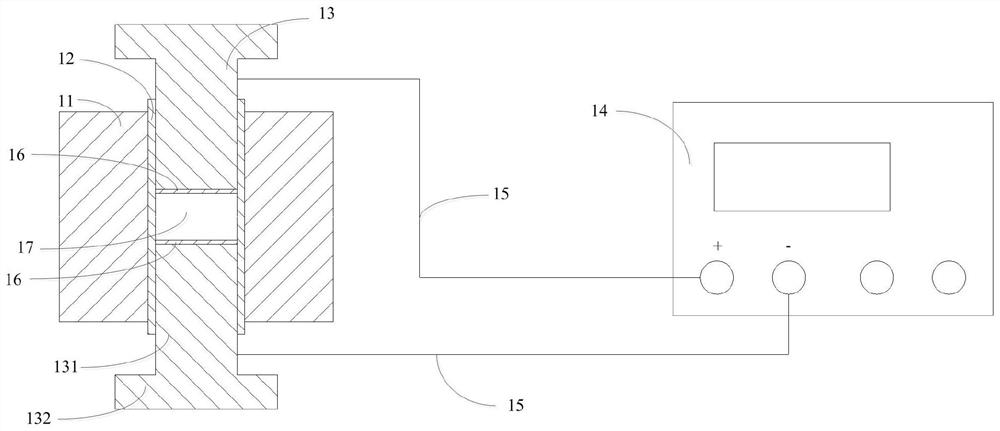

[0053] refer to figure 1 , the first aspect of the present invention provides a method for preparing a bismuth telluride-based thermoelectric material. The preparation device for a bismuth telluride-based thermoelectric material includes: a mold assembly, the mold assembly has a forming hole with an insulating inner wall; a conductive voltage head, a conductive voltage head It has an indenter column, the outer diameter of the indenter column is equal to the inner wall of the forming hole; the power supply component and the pressurized component; the method includes: pressing Bi, Te, Se powder into Bi 2 Te 3-x Se x The stoichiometric ratio weighs the ingredients and grinds them evenly, where 0≤x≤3; arrange the ground powder in the forming hole to form the following structure: the pressure head columns of the two conductive pressure heads are embedded in the two ends of the forming hole, and the grinding The finished powder is located in the forming hole and between the two co...

Embodiment 1

[0087] Using Bi, Te, Se powder as raw materials, according to Bi 2 Te 2.7 Se 0.3 Stoichiometric ratio Weigh the ingredients and mix them with an agate mortar for 30 minutes to achieve uniformity. Roll up the mica paper with a thickness of 0.15mm and put it into the mold hole. The length of the mica paper is slightly larger than the height of the mold to form the forming hole.

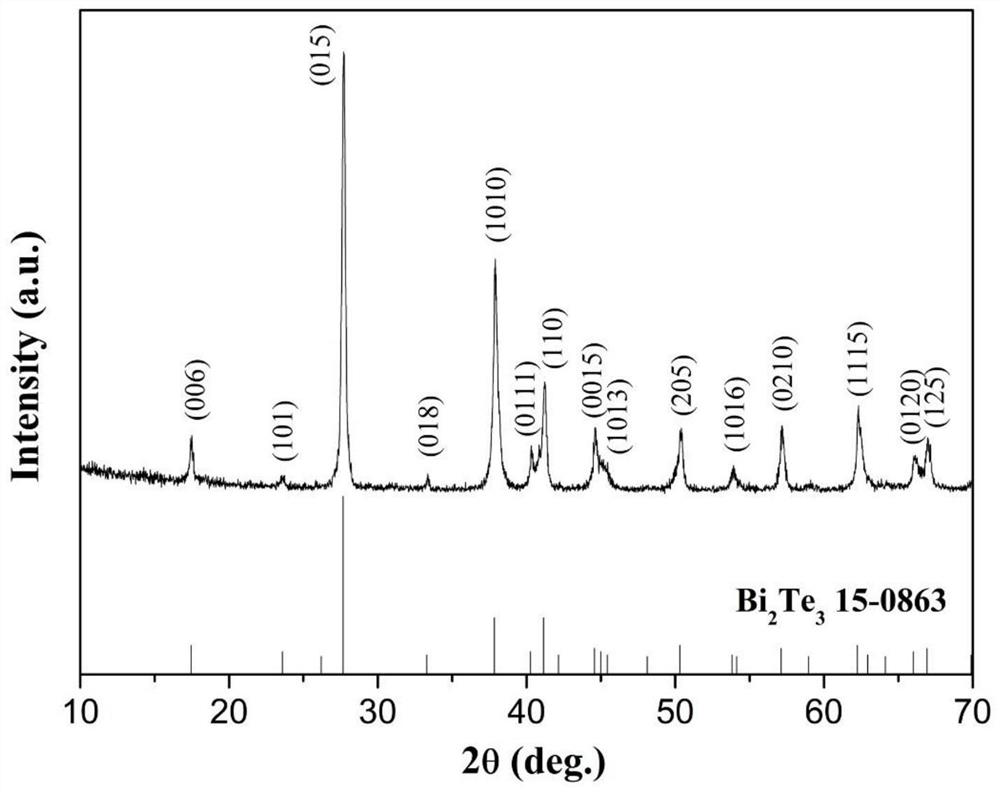

[0088] Then put the lower conductive pressure head and the graphite paper with a thickness of 0.2mm successively, put the powder raw material into the mold, further put the graphite paper with a thickness of 0.2mm and the upper conductive pressure head, and apply an axial pressure of 20MPa with a tablet press , release the pressure after holding the pressure for 5 minutes; connect the conductive head to the power supply, the preset voltage is 10V, and the current density is 8A / cm 2 , output an electric field to the sample, energize at a preset current density for 5s in a constant current state, and e...

Embodiment 2

[0090] Using Bi, Te, Se powder as raw materials, according to Bi 2 Te 2.7 Se 0.3 Stoichiometric ratio Weigh the ingredients and mix them with an agate mortar for 30 minutes to achieve uniformity. Roll up the mica paper with a thickness of 0.15mm and put it into the mold hole. The length of the mica paper is slightly larger than the height of the mold to form the forming hole.

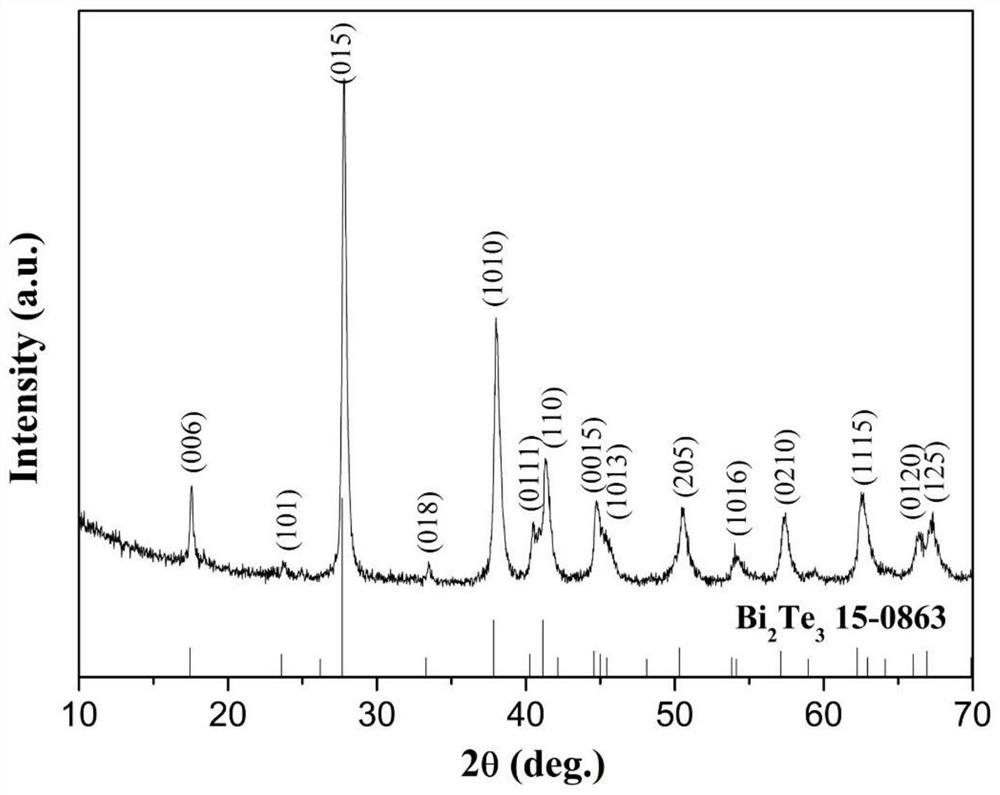

[0091] Then put the lower conductive pressure head and the graphite paper with a thickness of 0.2mm successively, put the powder raw material into the mold, further put the graphite paper with a thickness of 0.2mm and the upper conductive pressure head, and apply an axial pressure of 1.5MPa with a tablet machine. Pressure, release the pressure after holding the pressure for 5 minutes; connect the conductive pressure head to the power supply, the preset voltage is 10V, and the current density is 25A / cm 2 , output an electric field to the sample, energize at a preset current density for 2s in a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com