Manufacturing method of high-gluability flame-retardant plywood

A plywood and gluing technology, which is used in the joining of wooden veneers, chemical instruments and methods, manufacturing tools, etc., can solve the problems of poor hydrophilic performance of plywood, easy degumming of plywood, affecting the service life of plywood, etc. temperature, reducing energy consumption, improving the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

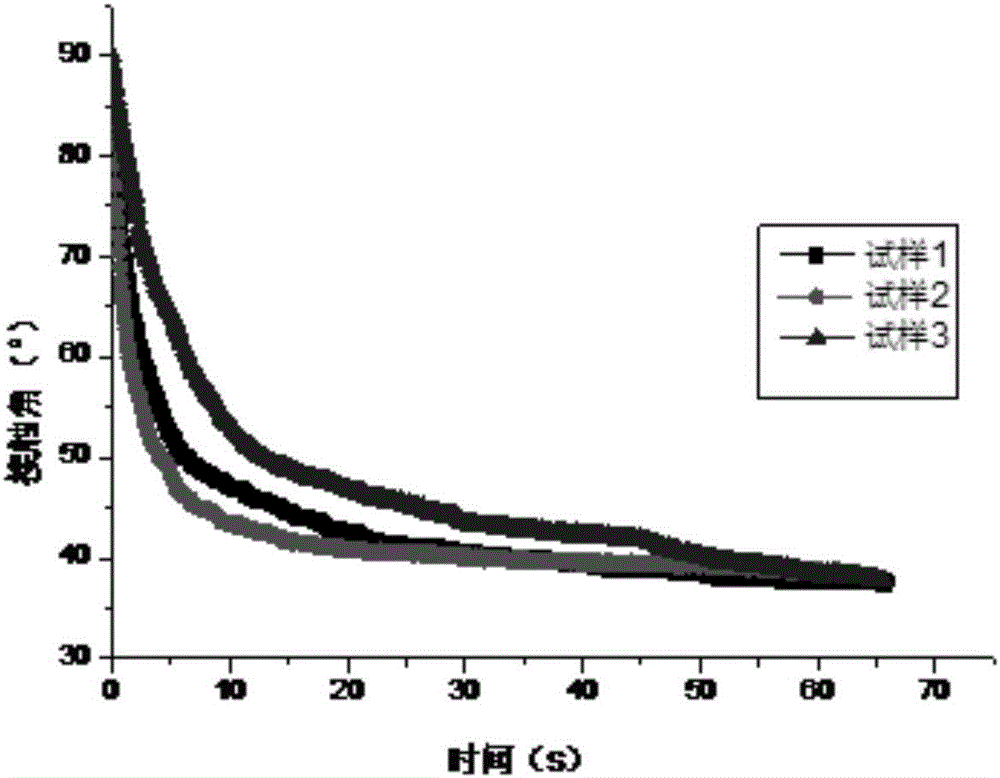

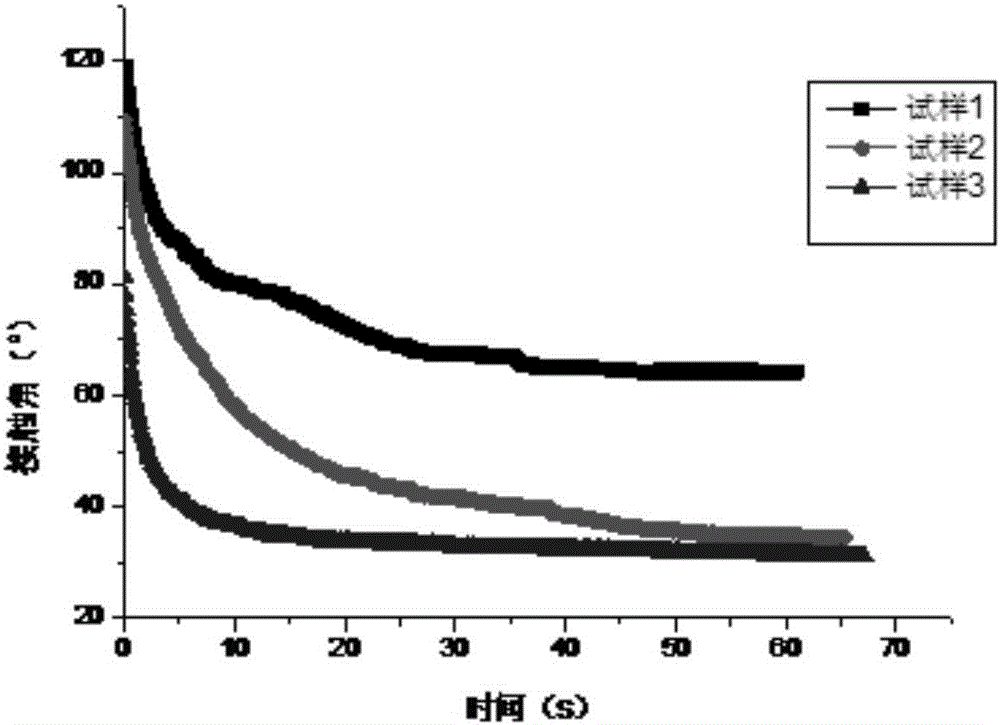

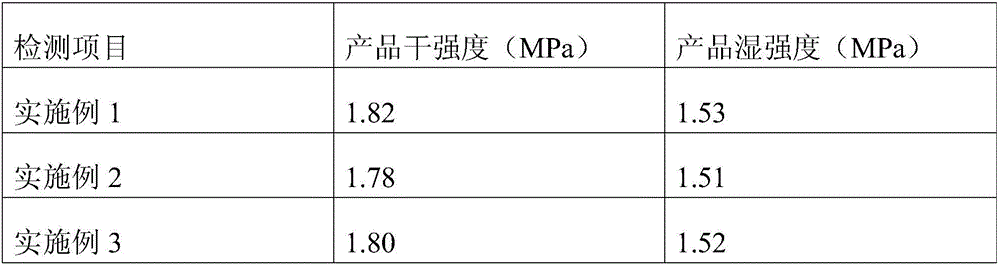

Embodiment 1

[0032] Self-made melamine modified urea-formaldehyde resin (MUF) resin is prepared by the following steps:

[0033] (a) Take 424g of formaldehyde and 1.5g of polyvinyl alcohol (PVA), mix them in a four-neck flask, start stirring, adjust the pH value of the mixture to 7.5-8.5 with 40% sodium hydroxide solution, add urea (U1) 149.2 g. Melamine 15g, heat up to 90°C within 10 minutes and adjust the pH value to 7.0-8.0 to obtain the mixed solution 1, keep it warm for 50 minutes, and make the mixed solution pH value 6.5-8.0 during the heat preservation period;

[0034] (b) Add formic acid solution to the mixed solution 1 obtained in step (a) twice, add formic acid solution for the first time to adjust the pH value to 5.0-7.0, keep the temperature at 85°C for 30 minutes, then add formic acid solution for the second time , that is, add a small amount of formic acid solution, when flake precipitation occurs, it means reaching the end point, once the end point is reached, immediately us...

Embodiment 2

[0041] Self-made melamine modified urea-formaldehyde resin (MUF) resin is prepared by the following steps:

[0042](a) Take 424g of formaldehyde and 1.5g of polyvinyl alcohol (PVA), mix them in a four-neck flask, start stirring, adjust the pH value of the mixture to 7.5-8.5 with 40% sodium hydroxide solution, add urea (U1) 149.2 g. Melamine 15g, heat up to 90°C within 30 minutes and adjust the pH value to 7.0-8.0 to obtain the mixed solution 1, keep it warm for 30 minutes, and make the mixed solution pH value 6.5-8.0 during the heat preservation period;

[0043] (b) Add formic acid solution to the mixed solution 1 obtained in step (a) twice, add formic acid solution for the first time to adjust the pH value to 5.0-7.0, keep the temperature at 95°C for 30 minutes, then add formic acid solution for the second time , that is, add a small amount of formic acid solution, when flake precipitation occurs, it means reaching the end point, once the end point is reached, immediately use...

Embodiment 3

[0050] Self-made melamine modified urea-formaldehyde resin (MUF) resin is prepared by the following steps:

[0051] (a) Take 424g of formaldehyde and 1.5g of polyvinyl alcohol (PVA), mix them in a four-neck flask, start stirring, adjust the pH value of the mixture to 7.5-8.5 with 40% sodium hydroxide solution, add urea (U1) 149.2 g. Melamine 15g, heat up to 90°C within 20 minutes and adjust the pH value to 7.0-8.0 to obtain the mixed solution 1, keep it warm for 40 minutes, and make the mixed solution pH value 6.5-8.0 during the heat preservation period;

[0052] (b) Add formic acid solution to the mixed solution 1 obtained in step (a) twice, add formic acid solution for the first time to adjust the pH value to 5.0-7.0, keep the temperature at 90°C for 30 minutes, then add formic acid solution for the second time , that is, add a small amount of formic acid solution, when flake precipitation occurs, it means reaching the end point, once the end point is reached, immediately us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com