Hot-pressed iron coke for ironmaking and preparation method thereof

A technology of iron coke and hot press forming, which is applied in the field of iron and steel metallurgy, can solve the problems of complex whole process, high raw material performance requirements, increased ash content, etc., and achieve simple production process, broad industrial application prospects, and improved gas utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

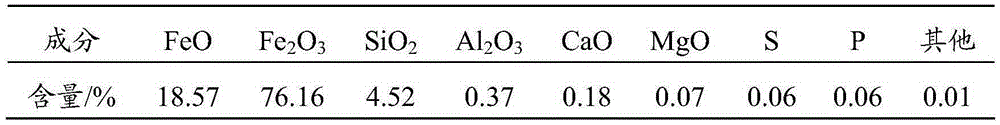

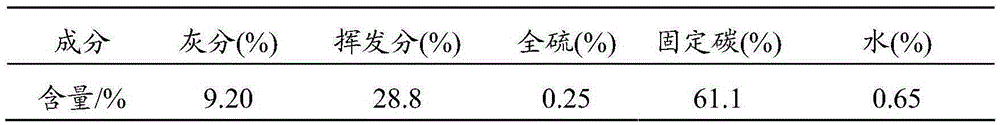

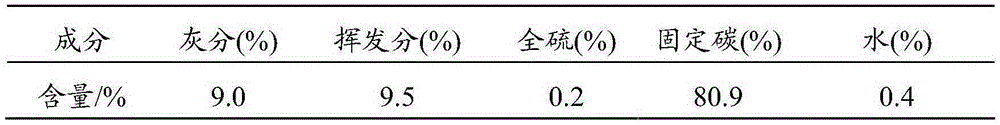

[0036] This invention is in its implementation process, with iron ore powder, bituminous coal powder and anthracite coal powder used by a certain company as raw materials, the main components of iron ore powder used are shown in Table 1, and the chemical components of bituminous coal used are shown in Table 2. The chemical composition of anthracite is shown in Table 3. Among iron ore powders, 100% have particle sizes less than 0.15mm, and 60% have particle sizes less than 0.075mm; among The colloidal layer index is 11; in the anthracite coal powder, the particle size is less than 0.15mm, accounting for 100%, and the particle size is less than 0.075mm, accounting for 70%.

[0037] Table 1 The main components of a certain iron ore powder

[0038]

[0039] Table 2 Industrial analysis of a bituminous coal powder

[0040]

[0041] Table 3 Industrial analysis of an anthracite coal powder

[0042]

[0043] The hot-pressed iron coke is batched according to the mass percent...

Embodiment 2

[0047] Iron ore powder, bituminous coal powder, and anthracite coal powder in Example 1 are used as raw materials.

[0048] The hot-pressed iron coke is batched in proportions of 20% of iron ore powder, 70% of bituminous coal powder and 10% of anthracite coal powder according to the mass percentage. After the three materials are mixed evenly, the mixture is heated to 250°C, and then quickly hot-pressed to obtain hot-pressed iron coke green balls. The compressive strength of the green balls is 784N, and the average drop strength is 5.2 times per piece.

[0049] The iron coke green pellets are placed in a tunnel kiln, and in a non-oxidizing atmosphere, they go through three stages of heating, high-temperature carbonization, and stew cooling in a dry distillation method. The heating rate is 3°C / min, and the high-temperature carbonization temperature is 900°C. The high-temperature carbonization time is 4 hours, and after taking it out, the stewed material is cooled to obtain hot-p...

Embodiment 3

[0052] Iron ore powder, bituminous coal powder, and anthracite coal powder in Example 1 are used as raw materials.

[0053] The hot-pressed iron coke is batched according to the mass fraction of iron ore powder 15%, bituminous coal powder 75%, and anthracite coal powder 10%. After the three materials are mixed evenly, the mixture is heated to 300°C, and then hot-pressed to form hot-pressed iron coke green balls. The compressive strength of the green balls is 980N, and the average drop strength is 6.5 times per piece.

[0054] The iron coke green pellets are placed in a tunnel kiln, and in a non-oxidizing atmosphere, they go through three stages of heating, high-temperature carbonization, and stew cooling in a dry distillation method. The heating rate is 3°C / min, and the high-temperature carbonization temperature is 1000°C. The high-temperature carbonization time is 3 hours, and after taking it out, the stewed material is cooled to obtain hot-pressed iron coke.

[0055] The si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com