Preparation method of bio oil-phenol-methanal copolycondensation resin wood adhesive

A technology of wood adhesive and co-condensation resin, which is applied in the fields of fine chemicals and polymer materials, can solve the problems of high production cost of phenolic resin, poor ecological environmental protection, and high dependence on petrochemical resources, and achieve good waterproof performance and reduce Pyrolysis problems and time, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

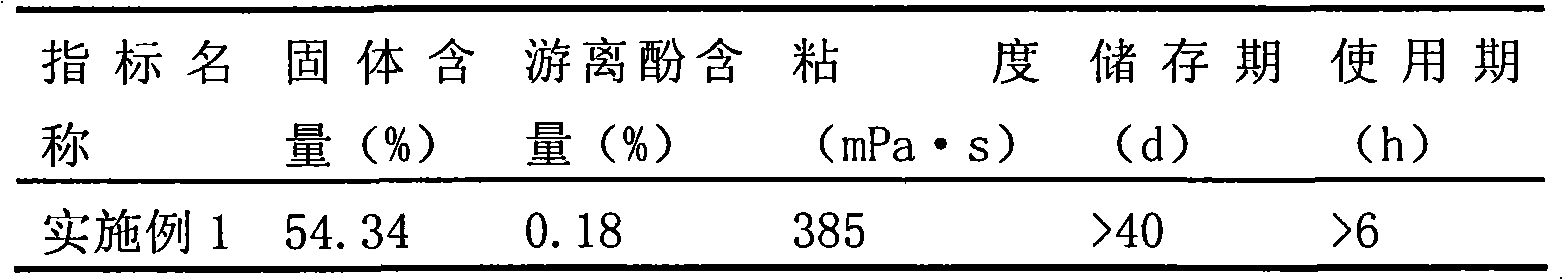

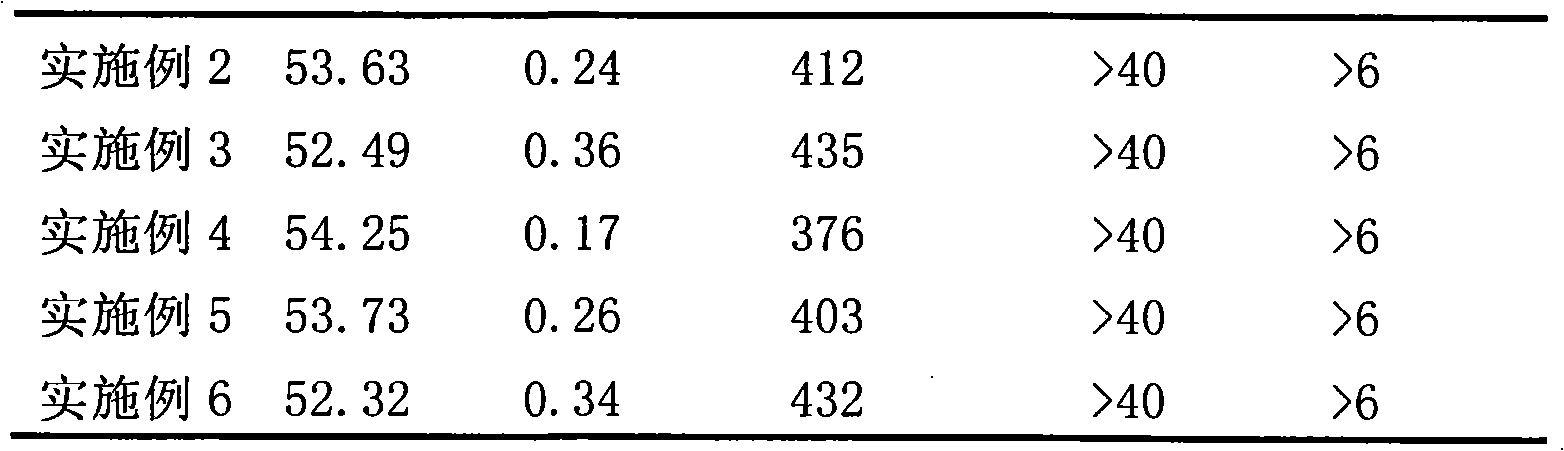

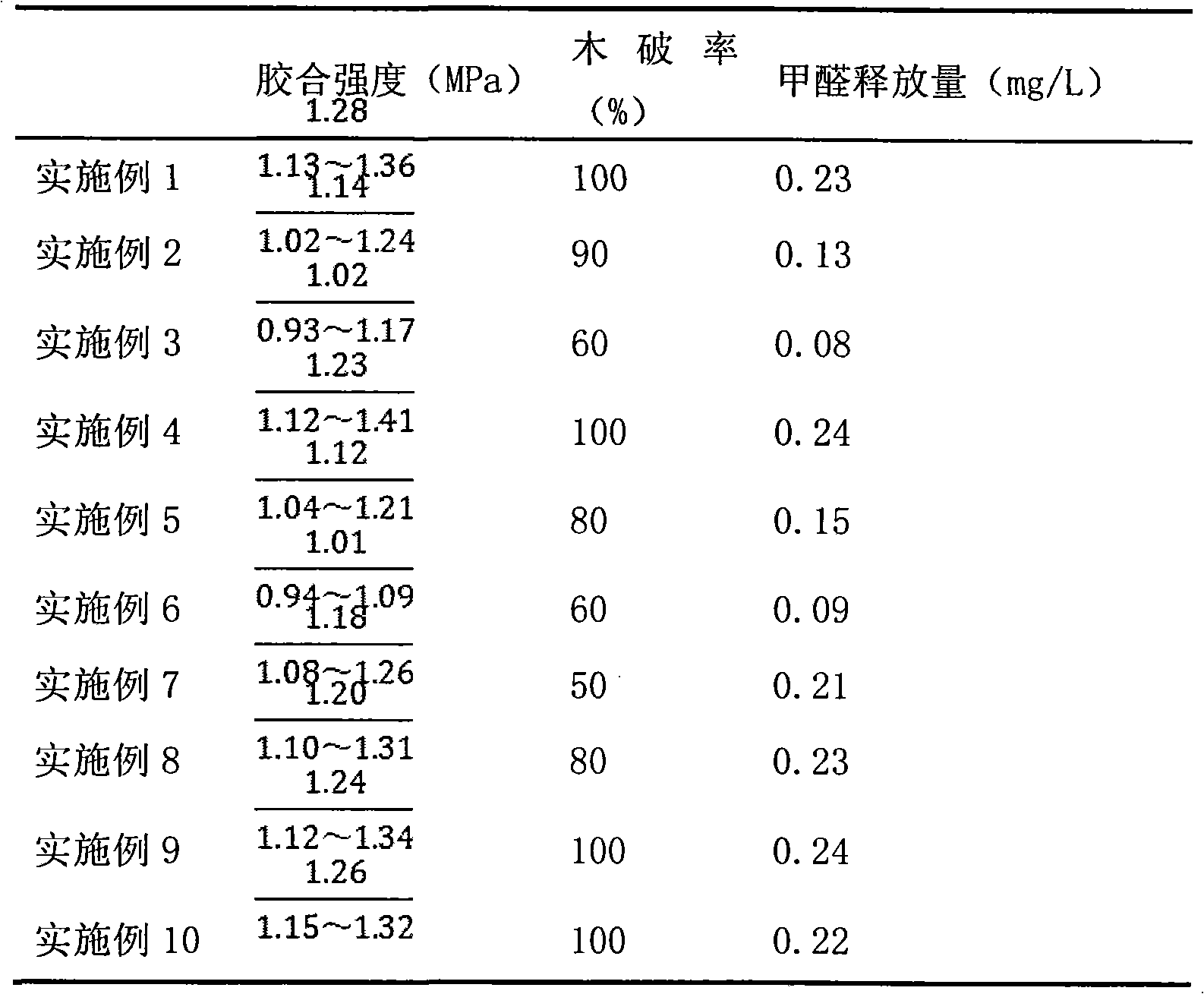

Examples

preparation example Construction

[0018] The preparation method of bio-oil-phenol-formaldehyde polycondensation resin wood adhesive proposed by the present invention comprises the following steps:

[0019] (1) Filter the bio-oil, remove the granular carbon therein, add an organic solvent in the filtered bio-oil, the mass ratio of adding is: bio-oil: organic solvent=(1~2): 1, let stand for 30 minutes Finally, the solution is divided into the first organic phase and the first inorganic phase, separate the first inorganic phase solution, rinse the first organic phase solution with distilled water, and then add hydrogen carbonate with a concentration of 10% to 20% in the first organic phase solution Sodium solution, mixed evenly and allowed to stand for 30 minutes, the solution was divided into the second organic phase and the second inorganic phase, the second inorganic phase was separated, and the organic solvent in the second organic phase was removed by vacuum distillation to obtain refined bio-oil ;

[0020]...

Embodiment 1

[0026] 1. Use a quantitative filter paper with a pore size of 30 to 50 microns to filter out the granular carbon part in the bio-oil, add organic solvent ethyl acetate to the filtered bio-oil, and the mass ratio added is bio-oil: ethyl acetate=1: 1. After standing for 30 minutes, the solution is divided into the first organic phase A phase and the first inorganic phase B phase. Phase A is the part dissolved in the organic solvent, and phase B is the part insoluble in the organic solvent; use a separating funnel to separate For phase B, wash phase A solution repeatedly with distilled water to remove some water-soluble substances, then dissolve phase A in a 10% sodium bicarbonate solution, mix well, and after standing for 30 minutes, the solution is divided into the second organic phase C phase And the second inorganic phase D phase, C phase is the part that does not dissolve in 10% sodium bicarbonate solution, and D phase is the part that dissolves in 10% sodium bicarbonate solu...

Embodiment 2

[0037] 1. Use a quantitative filter paper with a pore size of 30 to 50 microns to filter out the granular carbon part in the bio-oil, add the organic solvent butyl acetate to the filtered bio-oil, and the mass ratio added is bio-oil: butyl acetate=1.5: 1. After standing for 30 minutes, the solution is divided into the first organic phase A phase and the first inorganic phase B phase. Phase A is the part dissolved in the organic solvent, and phase B is the part insoluble in the organic solvent; use a separating funnel to separate For phase B, wash phase A solution repeatedly with distilled water to remove some water-soluble substances, then dissolve phase A in 15% sodium bicarbonate solution, mix well, and after standing for 30 minutes, the solution is divided into the second organic phase C phase And the second inorganic phase D phase, C phase is the part that is insoluble in 15% sodium bicarbonate solution, and D phase is the part that is dissolved in 15% sodium bicarbonate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com