Aldehyde-free veneer and producing method thereof

A manufacturing method and technology of plywood, applied in the direction of manufacturing tools, chemical instruments and methods, wood layered products, etc., can solve the problem of high cost of plywood, achieve the effect of reducing hot pressing time, reducing hot pressing pressure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

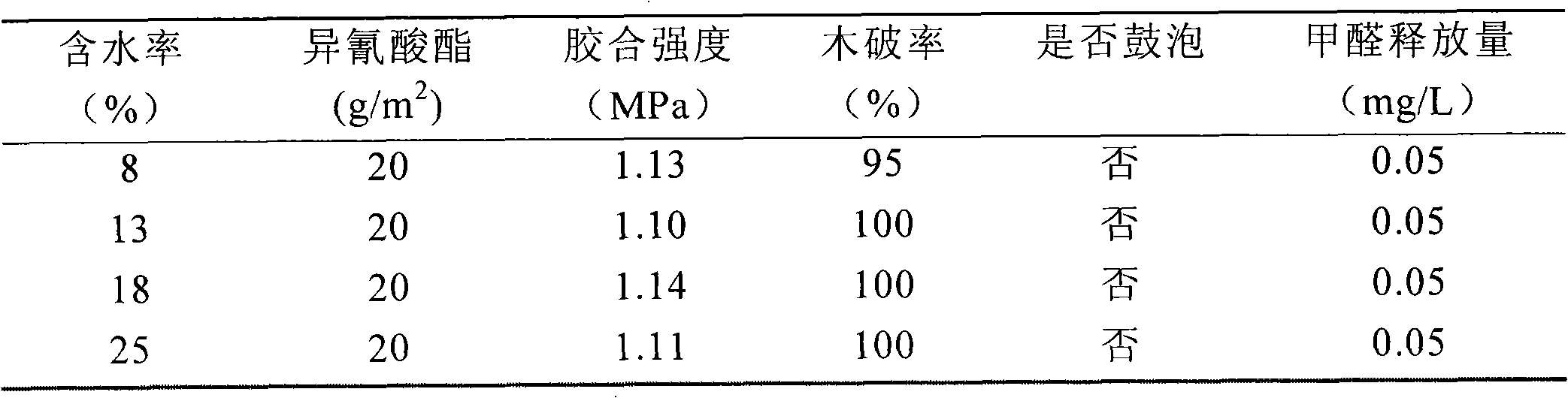

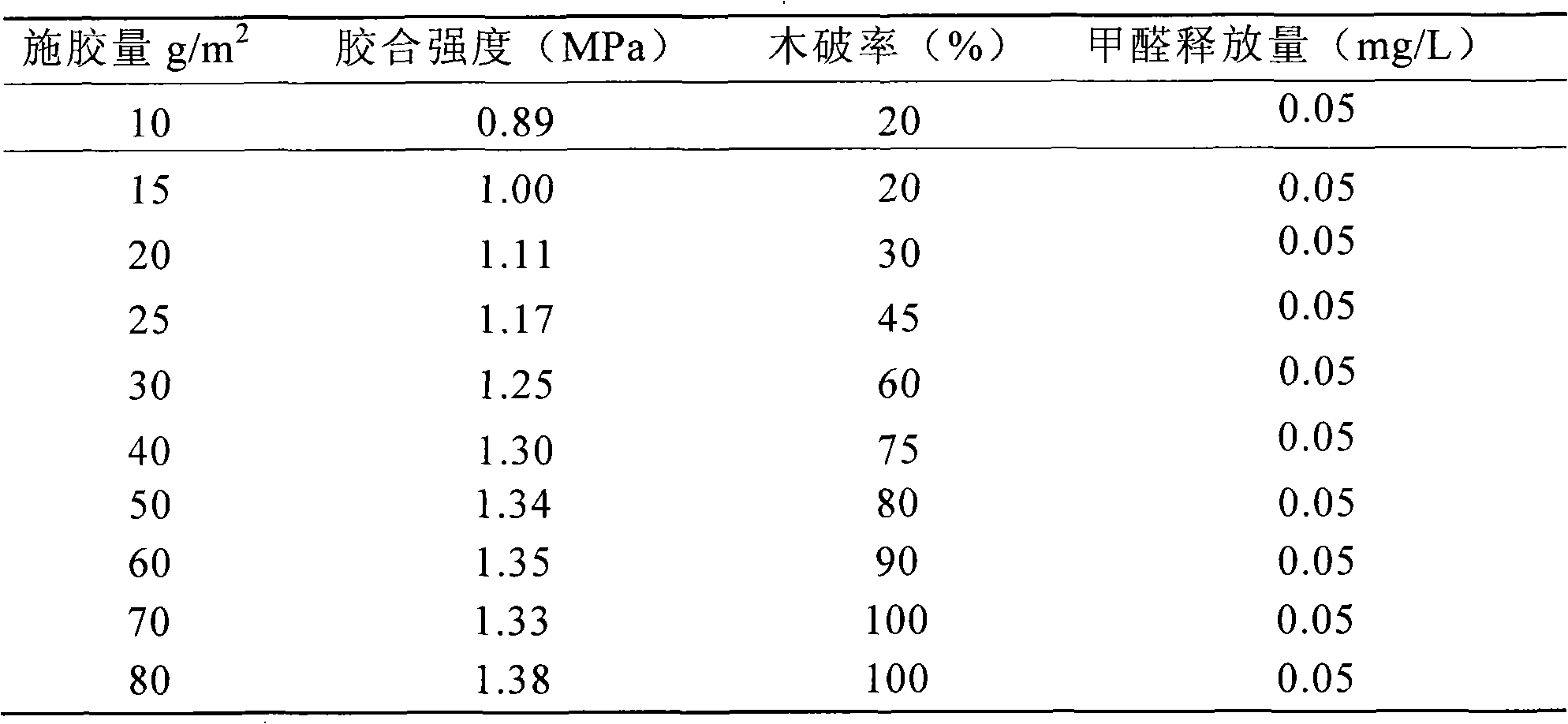

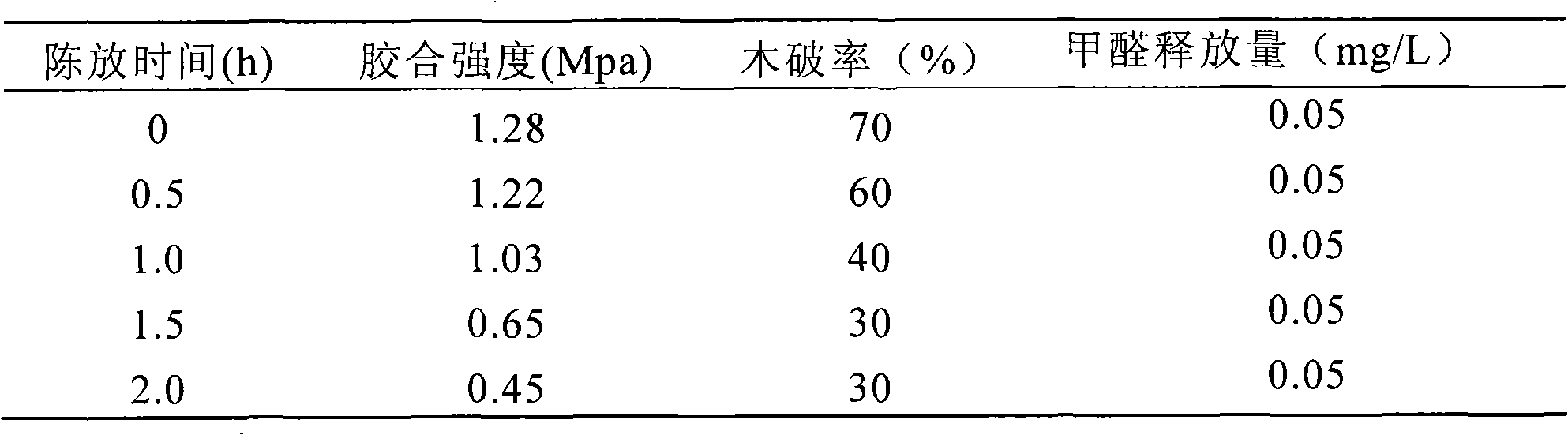

[0066] According to the results, select the following process parameters: the amount of sizing is 20g / m 2 ; The moisture content of the slab is 20%; no aging; the hot pressing temperature is 105g / m 2 The hot pressing pressure is 1.0Mpa; the hot pressing time is 1.0min / mm; poplar, birch, and eucalyptus veneers are used as materials respectively, and three-layer plywood is made with isocyanate adhesive. According to GB / T9846.3-2004, the bonding strength, wood breakage rate and formaldehyde emission of plywood were tested, and compared with the formaldehyde emission of poplar, birch and eucalyptus. The results are shown in Table 7.

[0067] Table 7 Experimental results of bonding strength of several types of plywood

[0068] Eucalyptus veneer: 2500cm×1300cm×0.5cm Poplar veneer: 2500cm×1300cm×0.2cm; Birch veneer: 2500cm×1300cm×0.14cm; Eucalyptus veneer: 2500cm×1300cm×0.2cm.

[0069]

[0070] It can be seen from Table 7 that the bonding strength of the wood in 3 is higher than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com