Sound insulation and noise reduction type composite bamboo fiberboard

A technology of sound insulation and noise reduction layer and bamboo fiber, which is applied in the direction of bonding, lamination and layered products of wooden veneer, can solve the problem that bamboo fiber board does not have sound insulation and noise reduction performance, does not meet the requirements of decorative construction, and affects the performance of the board. and other problems, to achieve the effect of improving comprehensive use performance, excellent sound insulation and noise reduction performance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

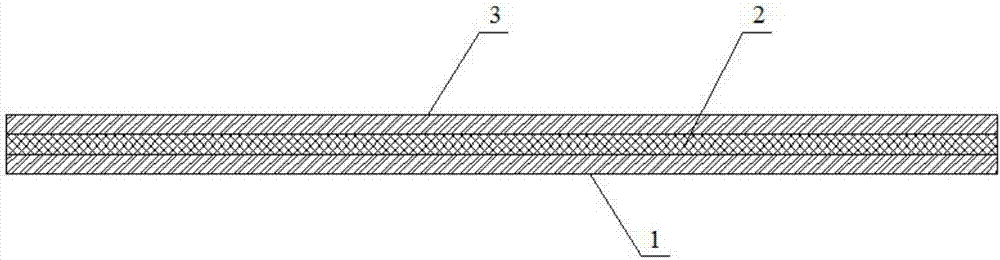

[0029] Such as figure 1 Shown, a kind of sound-insulating and noise-reducing composite bamboo fiber board is made of a bamboo fiber base plate 1, a sound-insulating and noise-reducing layer 2 and a bamboo fiber panel 3 of a three-layer structure, and the sound-insulating and noise-reducing layer is arranged between the bamboo fiber base plate and the bamboo fiber panel , The sound insulation and noise reduction layer is made of asbestos wool-foamed aluminum-magnesium composite material.

Embodiment 2

[0031] Such as figure 1 Shown, a kind of sound-insulating and noise-reducing composite bamboo fiber board is made of a bamboo fiber base plate 1, a sound-insulating and noise-reducing layer 2 and a bamboo fiber panel 3 of a three-layer structure, and the sound-insulating and noise-reducing layer is arranged between the bamboo fiber base plate and the bamboo fiber panel , The sound insulation and noise reduction layer is made of asbestos wool-foamed aluminum-magnesium composite material.

[0032] Preparation of sound-insulating and noise-reducing composite bamboo fiber board: spread the preheated and pressed bamboo fiber base plate in a hot-pressing mold, and then spread asbestos wool-foamed aluminum-magnesium composite material on the bamboo fiber base plate and preheated and pressed The obtained bamboo fiber panel is then hot-pressed by a hot-press forming machine, with a hot-pressing temperature of 170-175° C., a hot-pressing pressure of 6.5-7 MPa, and a hot-pressing time of...

Embodiment 3

[0036] Such as figure 1 Shown, a kind of sound-insulating and noise-reducing composite bamboo fiber board is made of a bamboo fiber base plate 1, a sound-insulating and noise-reducing layer 2 and a bamboo fiber panel 3 of a three-layer structure, and the sound-insulating and noise-reducing layer is arranged between the bamboo fiber base plate and the bamboo fiber panel , The sound insulation and noise reduction layer is made of asbestos wool-foamed aluminum-magnesium composite material.

[0037] Preparation of sound-insulating and noise-reducing composite bamboo fiber board: spread the preheated and pressed bamboo fiber base plate in a hot-pressing mold, and then spread asbestos wool-foamed aluminum-magnesium composite material on the bamboo fiber base plate and preheated and pressed The obtained bamboo fiber panel is then hot-pressed by a hot-press forming machine, with a hot-pressing temperature of 170-175° C., a hot-pressing pressure of 6.5-7 MPa, and a hot-pressing time of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com