Suspended quakeproof sound-proof isolating layer structure and quakeproof sound-proof floor slab construction method

A construction method and technology of isolation layer, applied in the directions of sound insulation, shockproof, floor slab, etc., can solve the problems of general sound insulation effect and lack of shockproof performance, and achieve the effect of reducing transportation, large reduction, and artificial reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

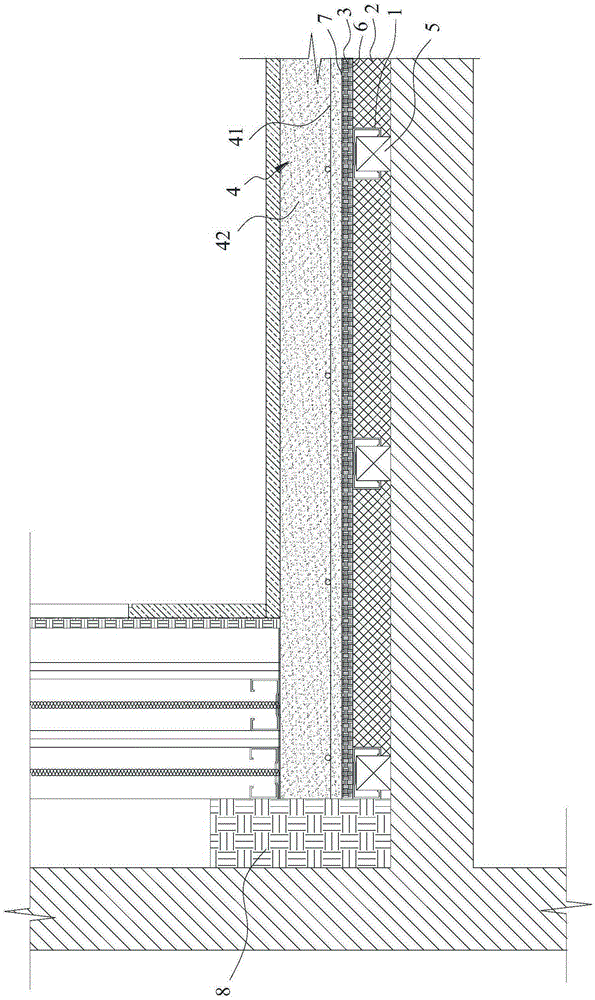

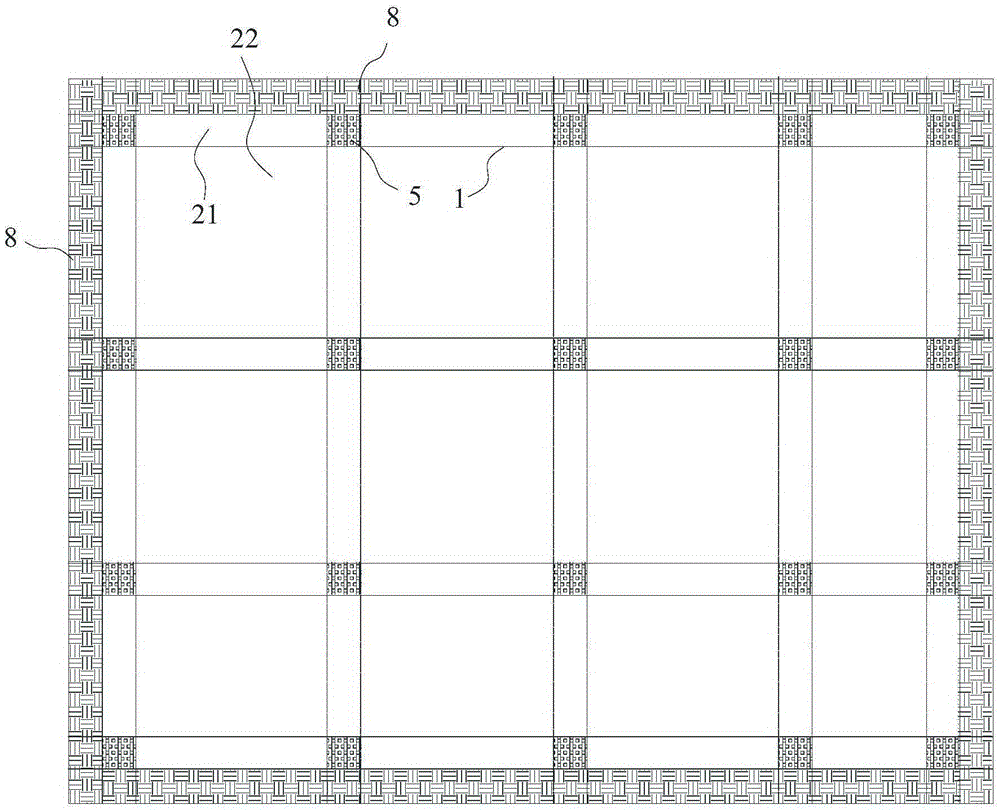

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0030] Such as Figure 1-2 The suspended shockproof and sound-insulating isolation layer structure shown includes a keel frame 1, a rock wool layer 2, a bamboo plywood 3, a reinforced concrete layer 4, and a plurality of shockproof pads 5, and each shockproof pad 5 is evenly spaced, and the keel frame 1 is clamped. Be fixed on each anti-vibration pad 5 side, rock wool layer 2 is laid between adjacent anti-vibration pads 5 and is laid in the gap of keel frame 1, the top surface of each anti-shock pad 5, the top surface of keel frame 1 and The top surface of the rock wool layer 2 is flush and combined to form a tiled surface, the bamboo plywood 3 is tiled on the tiled surface, and the reinforced concrete layer 4 is fixed on the top surface of the bamboo plywood 3 .

[0031] Among them, the keel frame 1 can be made of light steel keel, the rock wool layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com