Reflective thermal insulation energy-saving brick

A thermal insulation and reflective technology, applied in building materials, etc., can solve the problems of rising cost of flame retardants, difficulties in material quality supervision, etc., and achieve the effect of solving thermal insulation and fire prevention, reliable thermal insulation effect, and reducing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

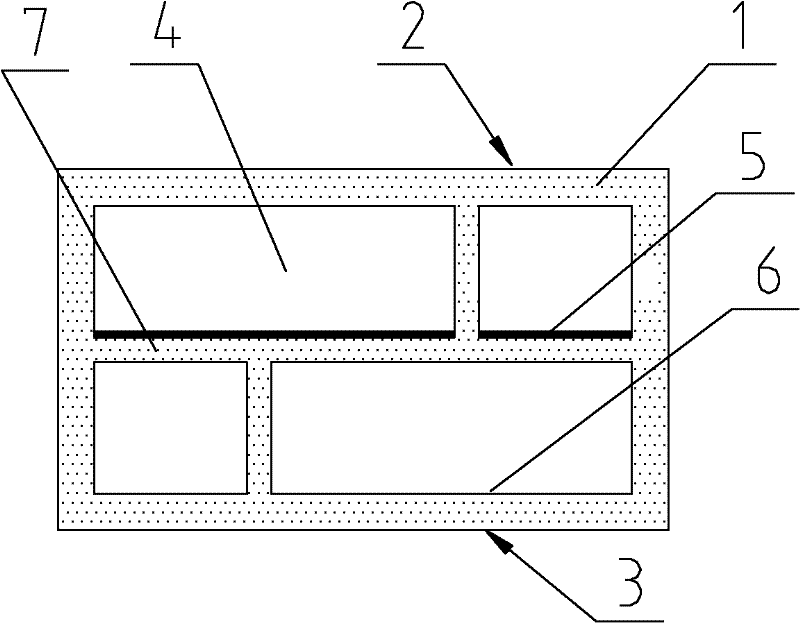

[0026] see figure 1 , when the through hole of the hollow brick body or the hollow block body is divided into two rows of multiple rectangular holes by the rib 7, each row has 2 holes, and the wall surface of the rib 7 on the side of the first row of rectangular holes facing the outer wall 2 A layer of reflective heat insulating material 5 is provided on it.

Embodiment 2

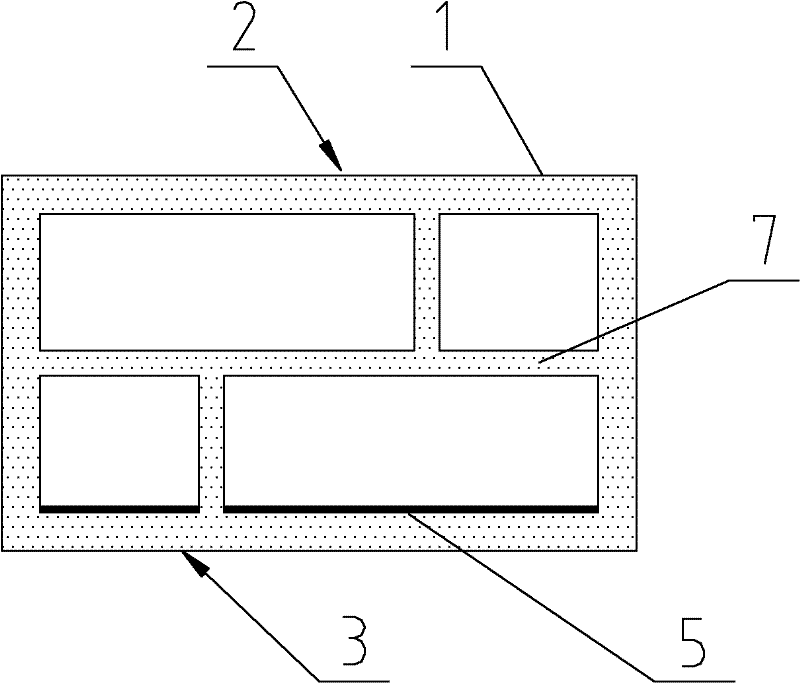

[0028] see figure 2 , when the through hole of the hollow brick body or the hollow block body is divided into two rows of multiple rectangular holes by ribs 7, the inner wall surface 3 on the side facing the outer wall 2 of the second row of rectangular holes is provided with a reflective heat insulating material layer 5 .

Embodiment 3

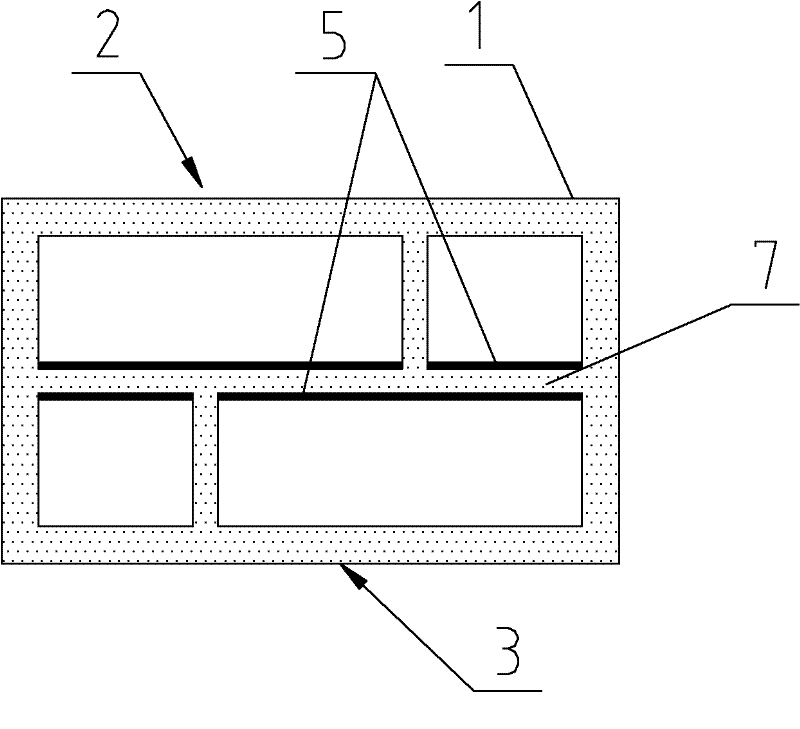

[0030] see image 3 , when the through hole of the hollow brick body or the hollow block body is divided into two rows of multiple rectangular holes by the rib 7, the upper and lower two wall surfaces of the rib 7 separating the through hole are respectively provided with a reflective heat insulating material layer 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com