Composite floor board and manufacturing technology thereof

A composite floor and substrate layer technology, applied in floor coverings, rosin adhesives, building structures, etc., can solve the problems of decorative pattern or texture blurring, affecting the decorative effect of the decorative layer, rough floor surface, etc., to achieve decorative Clearer patterns, better clarity and agility, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

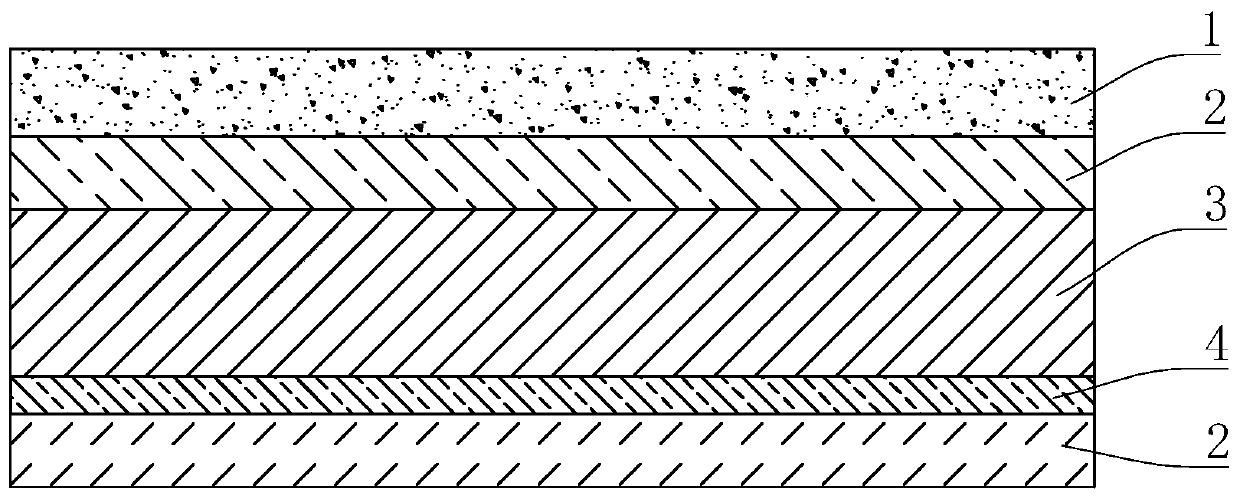

[0051] A composite floor, with reference to figure 1 , which includes a wear-resistant layer 1, a PVC pattern fabric layer 2, a substrate layer 3, a balance layer 4 and a sound-absorbing layer 5 arranged in sequence. Wherein, the wear-resistant layer 1 is a melamine wear-resistant paper layer; the base material layer 3 is an SPC base material layer; the balance layer 4 is a balance paper layer; the mute layer 5 is a cork layer.

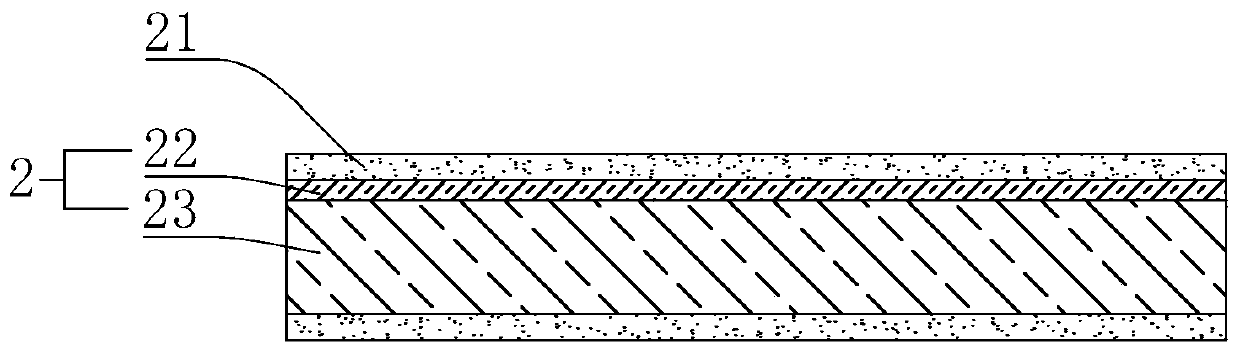

[0052] refer to figure 2 The PVC pattern fabric layer 2 includes a body layer 23 and a pattern layer 22 formed by printing water-based PVC ink on the front side of the body layer 23 . The front and back sides of the PVC pattern fabric layer 2 are all provided with an adhesive layer 21 . The adhesive layer 21 is formed by coating the glue configured according to the following ratio:

[0053] Chlorinated rubber 5g

[0054] Perchlorethylene resin 10g

[0055] Modified low molecular weight polyamide hot melt adhesive 5g

[0056] Highly Branched Tal...

Embodiment 2

[0066] A composite floor, with reference to figure 1 , which includes a wear-resistant layer 1, a PVC pattern fabric layer 2, a substrate layer 3, a balance layer 4 and a sound-absorbing layer 5 arranged in sequence. Wherein, the wear-resistant layer 1 is a melamine wear-resistant paper layer; the base material layer 3 is an SPC base material layer; the balance layer 4 is a melamine wear-resistant paper layer; the quiet layer 5 is an EVA foam layer.

[0067] refer to figure 2 The PVC pattern fabric layer 2 includes a body layer 23 and a pattern layer 22 formed by printing water-based PVC ink on the front side of the body layer 23 . The front and back sides of the PVC pattern fabric layer 2 are all provided with an adhesive layer 21 . The adhesive layer 21 is formed by coating the glue configured according to the following ratio:

[0068] Chlorinated rubber 2g

[0069] perchlorethylene resin 8g

[0070] Modified low molecular weight polyamide hot melt adhesive 2g

[0071...

Embodiment 3

[0081] A composite floor, with reference to figure 1 , which includes a wear-resistant layer 1, a PVC pattern fabric layer 2, a substrate layer 3, a balance layer 4 and a sound-absorbing layer 5 arranged in sequence. Among them, the wear-resistant layer 1 is a melamine wear-resistant paper layer; the substrate layer 3 is a WPC substrate layer; the balance layer 4 is composed of PVC film and melamine balance paper, and the PVC film is composited on the substrate layer 3; the mute layer 5 IXPE foam layer.

[0082] refer to figure 2 The PVC pattern fabric layer 2 includes a body layer 23 and a pattern layer 22 formed by printing oily PVC ink on the front side of the body layer 23 . The front and back sides of the PVC pattern fabric layer 2 are all provided with an adhesive layer 21 . The adhesive layer 21 is formed by coating the glue configured according to the following ratio:

[0083] Chlorinated rubber 3g

[0084] Perchlorethylene resin 10g

[0085] Modified low molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com