Lamination process, lamination equipment and mechanical hand applied to lamination equipment

A manipulator and lamination technology, applied in the field of manipulators, can solve the problems affecting the chemical formation interface, the poor bonding of the pole piece and the diaphragm, and the inability to transfer well, so as to improve the consistency, shorten the hot pressing time, and improve the bonding compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

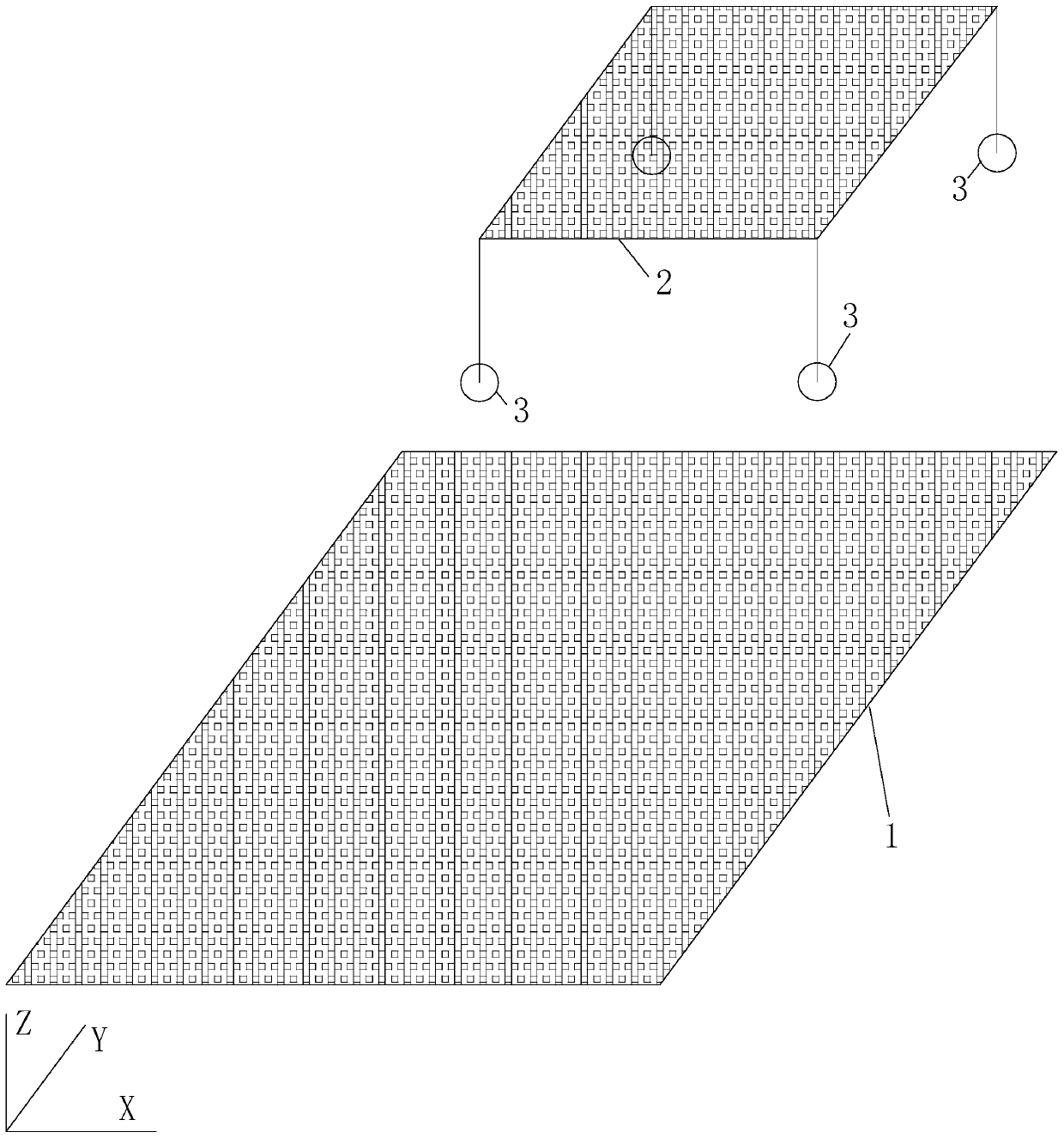

[0033] This embodiment provides a lamination equipment, which mainly includes a lamination table, a diaphragm unwinding mechanism, a pre-positioning platform 1, and a manipulator, wherein the lamination table is a lamination operation platform, on which the positive electrode sheet and the negative electrode sheet The laminations form a lithium-ion core pack. The diaphragm unwinding mechanism is used to unwind the diaphragm to the stacking table, the pre-positioning platform 1 is used to accurately position the pole pieces to ensure the positive and negative pole pieces in the lithium-ion core pack, and the manipulator is used for grasping pole piece.

[0034] Wherein, the pre-positioning platform 1 is provided with a pole piece positioning system for adjusting the precise position of the pole piece, so as to accurately adjust the pole piece to a predetermined position.

[0035] The manipulator is assembled on a movable manipulator, and the manipulator is located above the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com