Formaldehyde-free bamboo glulam and manufacturing method thereof

A manufacturing method and glulam technology, applied in the direction of manufacturing tools, wood processing appliances, and joining of wooden veneers, can solve problems such as poor gluing, reduce hot pressing pressure, increase moisture content, and lower hot pressing temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation,

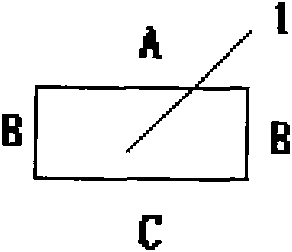

[0035] The material preparation process includes: selecting bamboo, sawing, cutting, rough planing, cooking (including anti-mildew, anti-moth and anti-corrosion treatment), drying, fine planing and other processes, which belong to the prior art. It is 20mm that bamboo is processed into chord surface width by above-mentioned operation, and diameter surface thickness is 5mm, and length is two kinds of specification bamboo strips of 2600mm and 1300mm (as figure 1 shown).

[0036] (2) Bamboo diameter surface sizing

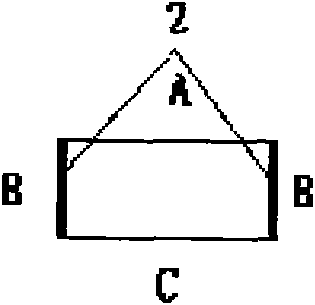

[0037] Bamboo strip diameter surface sizing adopts glue sizing method. The adhesive used is water-based polymer isocyanate adhesive. Quantitative water-based macromolecule isocyanate adhesive is evenly coated on the diameter surface of bamboo strips (such as figure 2 shown).

[0038](3) Dimensional splicing

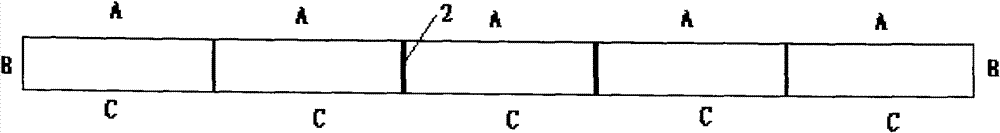

[0039] Splicing the bamboo strips on the diameter and surface, adopting the cold pressing method, using the bamboo strips with gl...

Embodiment 2

[0053] (1) Preparation,

[0054] The raw material preparation process includes: selecting bamboo, sawing, stripping, rough planing, carbonization, drying, fine planing and other processes, which belongs to the prior art. It is 20mm that bamboo material is machined into chord surface width by above-mentioned operation, and diameter surface thickness is 5mm, and length is the bamboo strip of 2600mm specification, (as figure 1 shown);

[0055] (2) Bamboo diameter surface sizing

[0056] Bamboo strip diameter surface sizing adopts roller gluing method. The adhesive used is polyvinyl acetate emulsion adhesive. Quantitative polyvinyl acetate emulsion adhesive is evenly coated on the radial surface of bamboo strips, (such as figure 2 shown).

[0057] (3) Dimensional splicing

[0058] Splicing the bamboo strips on the diameter surface, adopting the cold pressing method, the above-mentioned bamboo strips with glue applied to the diameter surface, using the manual assembly method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com