Phase-change metal thermal interface composite material and preparation method thereof

A technology of phase-change metals and composite materials, applied in heat exchange materials, metal layered products, chemical instruments and methods, etc., can solve problems such as short circuits, voids, and phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

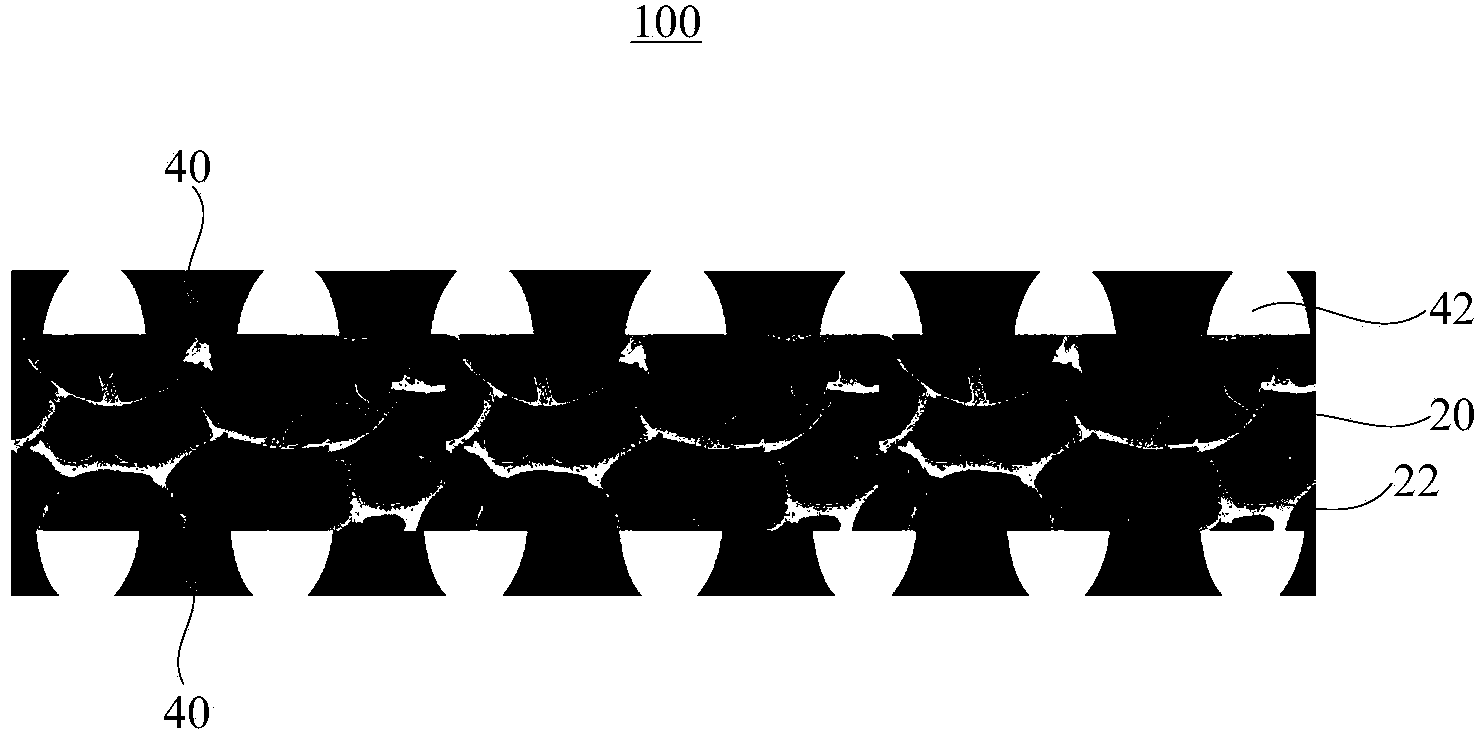

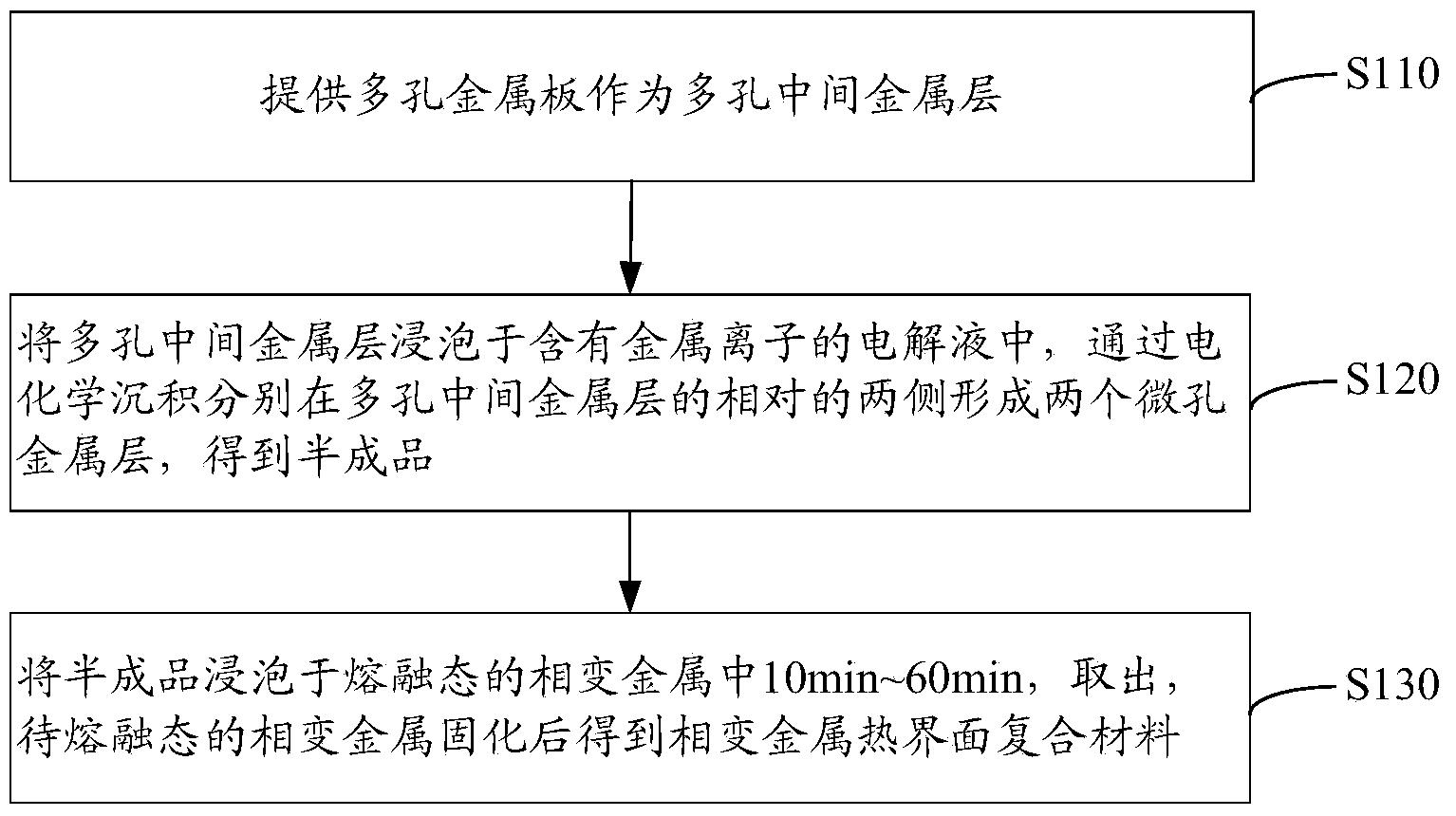

[0038] see figure 2 , a method for preparing a phase-change metal thermal interface composite material in an embodiment includes the following steps S110 to S130.

[0039] Step S110: providing a porous metal plate as a porous intermediate metal layer.

[0040] The porous intermediate metal layer is preferably a porous copper foam layer, a porous nickel foam layer, a porous aluminum foam layer or a porous silver foam layer.

[0041] Preferably, the thickness of the porous intermediate metal layer is 0.005mm-0.5mm. The porosity of the porous intermediate metal layer is 30% to 90%, preferably 60%.

[0042] Step S120: Soak the porous intermediate metal layer in an electrolyte solution containing metal ions, and form two microporous metal layers on opposite sides of the porous intermediate metal layer by electrochemical deposition to obtain a semi-finished product.

[0043]Electrolytes containing metal ions include sulfuric acid and metal ions. The metal ion is a metal ion cor...

Embodiment 1

[0057] Preparation of phase change metal thermal interface composites

[0058] 1. Provide a commercial porous foamed copper foil with a thickness of 0.068m and a porosity of 60% as the porous intermediate metal layer. The length × width of the porous intermediate metal layer is 25mm × 25mm;

[0059] 2. Soak the porous intermediate metal layer in an electrolyte solution containing 0.2M CuSO 4 and 1.0M of H 2 SO 4 , with a current of 9.42A, after electroplating for 30S, two microporous metal layers are formed on the opposite two sides of the porous intermediate metal layer to obtain a semi-finished product; the thickness of each microporous metal layer is 0.001mm, and each micropore There are multiple micropores on the metal layer, the diameter of the micropores is 30 μm, and the distance between two adjacent micropores is 30 μm to 50 μm;

[0060] 3. Mix 3.16g of metal bismuth with a purity greater than 99.9%, 1.96g of metal tin with a purity greater than 99.9%, and 4.88g of ...

Embodiment 2

[0068] Preparation of phase change metal thermal interface composites

[0069] 1. Provide a commercial porous nickel foam foil with a thickness of 0.024m and a porosity of 60% as the porous intermediate metal layer. The length × width of the porous intermediate metal layer is 25mm × 25mm;

[0070] 2. Soak the porous intermediate metal layer in the electrolyte, which contains 0.2M AlCl 3 and 1.0M of H 2 SO 4 , with a current of 15A, and after electroplating for 10S, two microporous metal layers are formed on the opposite two sides of the porous intermediate metal layer to obtain a semi-finished product; the thickness of each microporous metal layer is 0.0005mm, and each microporous metal layer There are multiple micropores on the layer, the diameter of the micropores is 50 μm, and the distance between two adjacent micropores is 40 μm to 50 μm;

[0071] 3. Mix 3.4g of metal bismuth with a purity greater than 99.9%, 1g of metal gallium with a purity greater than 99.9%, and 5.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com