Polycarbonate heat-conducting composite material and preparation method thereof

A thermally conductive composite material and polycarbonate technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of less addition of thermally conductive medium, high thermal conductivity of thermally conductive PC, and reduced PC performance, so as to improve fluidity. , The effect of improving processing performance and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

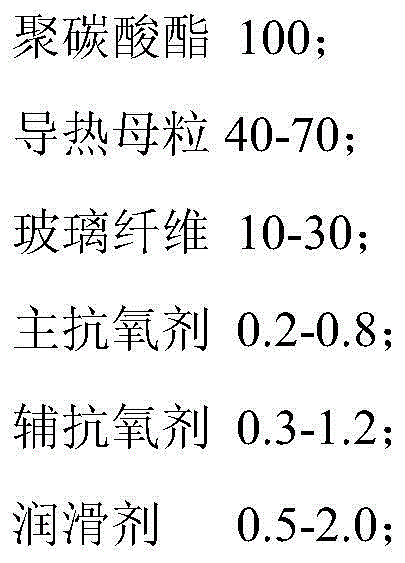

Method used

Image

Examples

Embodiment 1

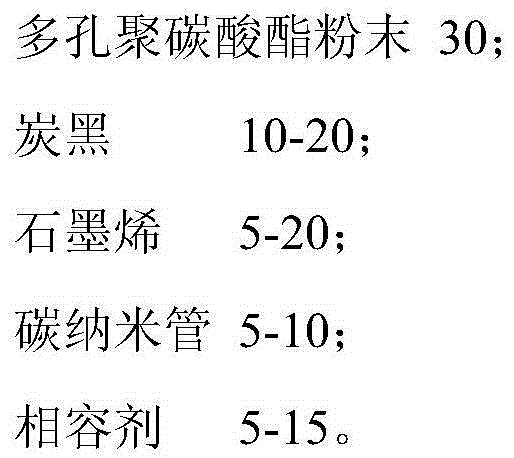

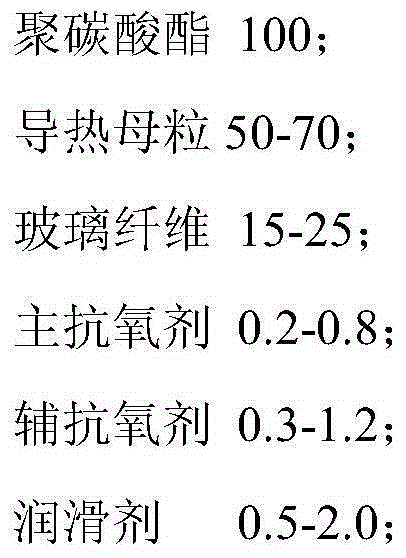

[0050] A kind of preparation method of polycarbonate thermally conductive composite material, the preparation of A, thermally conductive masterbatch: a, take by weighing 200g graphene, 50g carbon nanotube, 200g carbon black, 150g styrene-acrylonitrile-maleic anhydride copolymer and 300g porous polycarbonate powder, 200g graphene and 50g carbon nanotubes are uniformly dispersed and adsorbed on 200g dispersion carrier-carbon black by strong airflow dispersion method, and 450g heat conduction medium is obtained; b, 300g porous polycarbonate Carbonate powder, 450g heat conduction medium and compatibilizer 150g styrene-acrylonitrile-maleic anhydride copolymer are put into a high-speed mixer and fully mixed, and then extruded and granulated by a twin-screw extruder to obtain heat-conducting masterbatches. The temperature of each zone of the screw extruder is 230-260°C; B. Processing of heat-conducting composite materials: dry the pure polycarbonate powder at 110°C for 4 hours, then a...

Embodiment 2

[0052] A preparation method of polycarbonate thermally conductive composite material, A, the preparation of thermally conductive masterbatch: a, weigh 200g graphene, 70g carbon nanotube, 200g carbon black, 100g styrene-acrylonitrile-glycidyl methacrylate Copolymer and 300g porous polycarbonate powder, 200g graphene and 70g carbon nanotubes are uniformly dispersed and adsorbed on 200g dispersion carrier-carbon black by strong air flow dispersion method, and 470g heat conduction medium is obtained; b, 300g Porous polycarbonate powder, 470g of heat-conducting medium and 100g of compatibilizer styrene-acrylonitrile-glycidyl methacrylate are put into a high-speed mixer and mixed thoroughly, and then extruded and granulated by a twin-screw extruder to obtain a heat-conducting Masterbatch, the temperature in each zone of the twin-screw extruder is 230-260°C; B. Processing of heat-conducting composite materials: Dry the pure polycarbonate powder at 110°C for 4 hours, then accurately we...

Embodiment 3

[0054] A kind of preparation method of polycarbonate heat conduction composite material, the preparation of A, heat conduction masterbatch: a, take by weighing 150g graphene, 70g carbon nanotube, 150g carbon black, 100g POE grafted maleic anhydride and 300g porous polycarbonate Ester powder, 150g graphene and 70g carbon nanotubes are uniformly dispersed and adsorbed on 150g dispersion carrier-carbon black by strong airflow dispersion method, and 370g heat conduction medium is obtained; b, 300g porous polycarbonate powder, 370g Heat conduction medium and compatibilizer 100g POE grafted maleic anhydride is put into a high-speed mixer and fully mixed, and then extruded and granulated by a twin-screw extruder to obtain a heat-conductive masterbatch. The temperature of each zone of the twin-screw extruder is 230-260 ℃; B. Processing of thermally conductive composite materials: Dry the pure polycarbonate powder at 110°C for 4 hours, then accurately weigh 1283g of polycarbonate, 770g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com