Method for constructing composite structure tissue engineering bracket containing different extracellular matrixes

A technology of tissue engineering scaffold and composite structure, which is applied in medical science, prosthesis, etc., and can solve problems such as difficult to realize tissue engineering bone construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

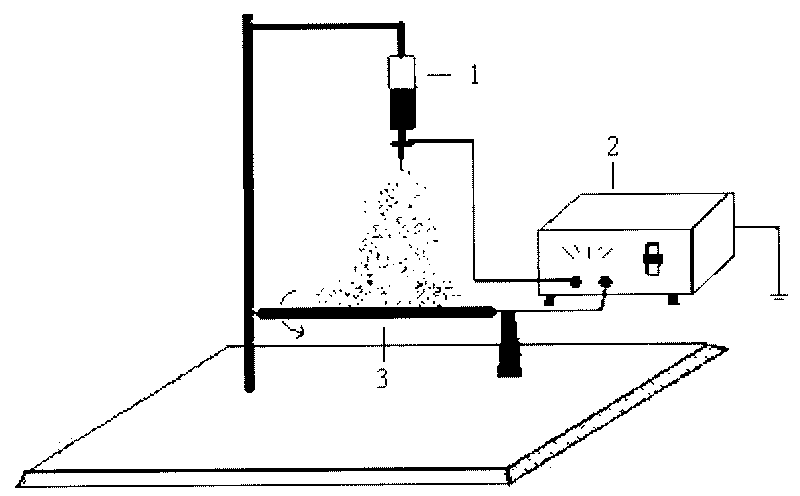

Method used

Image

Examples

Embodiment 1

[0032] a. Polylactic acid was dissolved in chloroform at a concentration of 8% (g / ml), and a stent was prepared by electrospinning technology. The electrospinning voltage is 20KV, the electrospinning distance is 12cm, the flow rate is 0.1ml / h, and the diameter of the receiving metal rod is 1mm.

[0033] b. Take off the vascular stent from the metal rod and dry it in vacuum. A stainless steel metal rod with a diameter of 0.8 mm is used to penetrate into the vascular stent.

[0034] c. Use a standard sieve to sieve 27 g of sodium chloride with a particle size of 224 to 300 μm as a porogen.

[0035] d. Weigh 3 g of polylactic acid and polycaprolactone at a mass ratio of 7:3 and dissolve in 40 ml of chloroform, and stir magnetically to dissolve.

[0036] e. Add the porogen obtained in step c to the polymer solution obtained in step d, stir with a glass rod to disperse the porogen evenly in the polymer solution, and form a pasty mixture containing the porogen with certain fluidit...

Embodiment 2

[0043] a. Polylactic acid-caprolactone copolymer and gelatin were dissolved together in chloroform at a concentration of 8% and 2% (g / ml) respectively, and stents were prepared by electrospinning technology. The electrospinning voltage is 20KV, the electrospinning distance is 12cm, the flow rate is 0.1ml / h, and the diameter of the receiving metal rod is 0.8mm.

[0044] b. Take off the vascular stent from the metal rod and dry it in vacuum. A stainless steel metal rod with a diameter of 0.6mm is used to penetrate into the vascular stent.

[0045] c. Use a standard sieve to sieve 27 g of sodium chloride with a particle size of 224 to 300 μm as a porogen.

[0046]d. Weigh 3 g of polylactic acid and polycaprolactone at a mass ratio of 6:4 and dissolve in 40 ml of chloroform, and stir magnetically to dissolve.

[0047] e. Add the porogen obtained in step c to the polymer solution obtained in step d, stir with a glass rod to disperse the porogen evenly in the polymer solution, and...

Embodiment 3

[0053] a. Polylactic acid and collagen were dissolved together in hexafluoroisopropanol at a concentration of 8% and 0.5% (g / ml) respectively, and the collagen vascular stent was prepared by electrospinning technology. The electrospinning voltage is 20KV, the electrospinning distance is 12cm, the flow rate is 0.1ml / h, and the diameter of the receiving metal rod is 1.5mm.

[0054] b. Take off the vascular stent from the metal rod and dry it in vacuum. A stainless steel metal rod with a diameter of 1.3 mm is used to penetrate into the vascular stent.

[0055] c. Use a standard sieve to sieve 27 g of sodium chloride with a particle size of 224 to 300 μm as a porogen.

[0056] d. Weigh 3 g of polylactic acid and polycaprolactone according to the mass ratio of 8:2 and dissolve in 40 ml of chloroform, and stir magnetically to dissolve.

[0057] e. Add the porogen obtained in step c to the polymer solution obtained in step d, stir with a glass rod to disperse the porogen evenly in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com