High-efficiency heat-conducting high-density fiberboard and manufacturing method thereof

A technology of high-density fiberboard and its manufacturing method, which is applied in the direction of flat products, other household appliances, household components, etc., can solve the problems of not many patented technologies on the thermal conductivity of fiberboard, difficulty in applying automatic production of fiberboard, and low initial viscosity of thermally conductive materials. Achieve good release of negative oxygen ions, good far-infrared heat radiation performance, and improve environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for manufacturing high-efficiency heat-conducting high-density fiberboards, comprising the following steps:

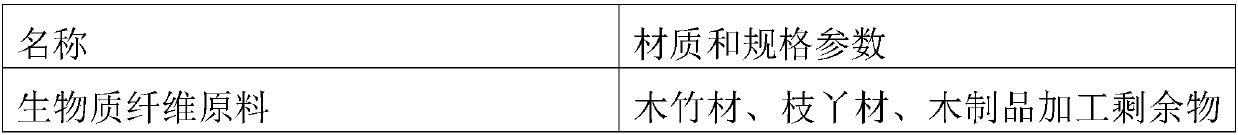

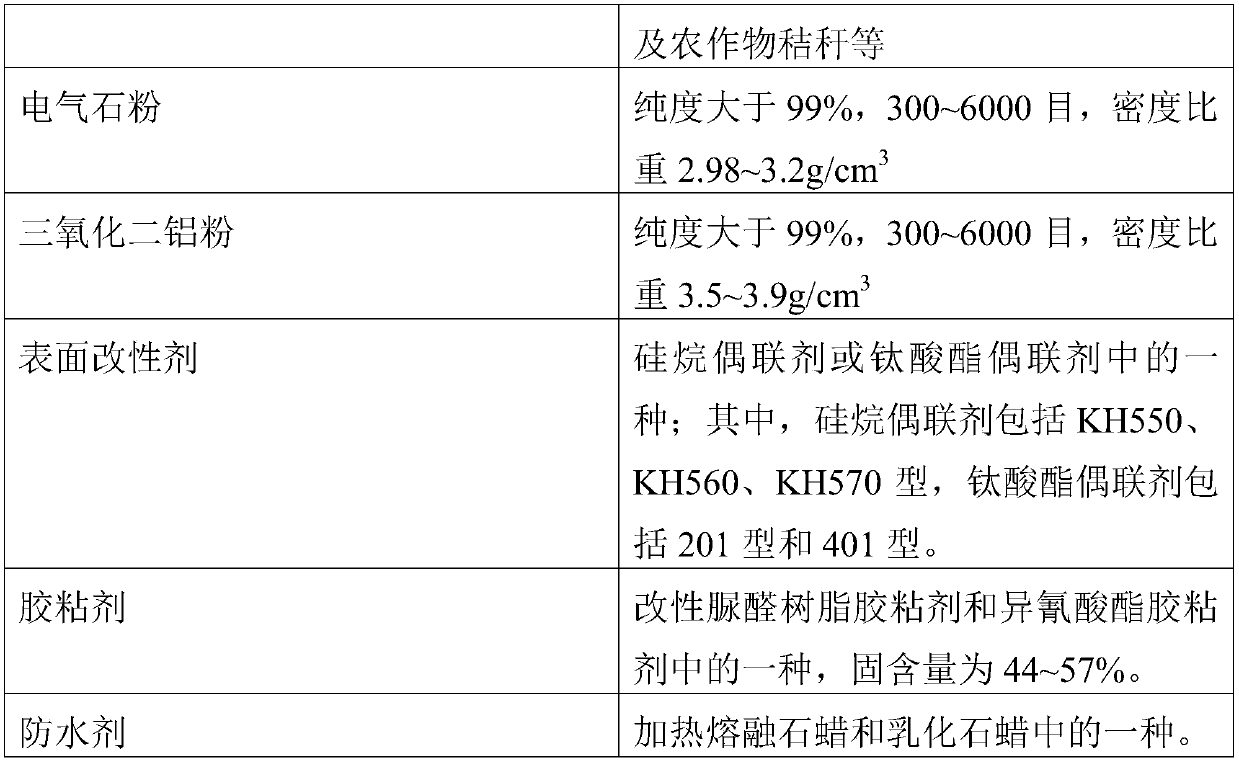

[0048] Step 1: Select wood and bamboo, branch wood, wood product processing residues, and biomass straw as biomass fiber raw materials, and then make fiber slurry.

[0049] Step 2: In the way of pressurized spraying, first spray the water mixture of heat-conducting material powder, surface modifier and the first part of adhesive into the fiber slurry; the heat-conducting material powder is tourmaline powder and aluminum oxide powder.

[0050] Step 3: Continue to apply the second part of adhesive separately, and then dry to obtain dry fibers.

[0051] Step 4: After the obtained dried fibers are assembled and pre-pressed, they are hot-pressed, trimmed, heat-dissipated and maintained, and sanded to make the high-efficiency heat-conducting high-density fiberboard.

Embodiment 2

[0053] A method for manufacturing high-efficiency heat-conducting high-density fiberboards, comprising the following steps:

[0054] Step 1: Select wood and bamboo, branch wood, wood product processing residues, and biomass straw as biomass fiber raw materials, and then make fiber slurry.

[0055] Step 2: In the way of pressurized spraying, first spray the water mixture of heat-conducting material powder, surface modifier and the first part of adhesive into the fiber slurry; the heat-conducting material powder is tourmaline powder and aluminum oxide powder. The thermally conductive material powder accounts for 5% of the dry fiber weight of the fiber slurry, and the tourmaline powder accounts for 10% of the total weight of the thermally conductive material powder; the amount of surface modifier is 0.6% of the total weight of the thermally conductive material powder; the first and the total amount of the second part of the adhesive is 13% of the total weight of the dry fiber and...

Embodiment 3

[0059] A method for manufacturing high-efficiency heat-conducting high-density fiberboards, comprising the following steps:

[0060] Step 1: Select wood and bamboo, branch wood, wood product processing residues, and biomass straw as biomass fiber raw materials, and then make fiber slurry. The fiber slurry is obtained from biomass fiber raw materials through flaking, screening, cooking, and thermal grinding; wherein, molten paraffin or emulsified paraffin is applied as a waterproofing agent during thermal grinding, and the dosage is 0.7% of the total amount of dry fibers in the fiber slurry. %; The cooking temperature is 120°C and the steam pressure is 6.0 kg.

[0061] Step 2: In the way of pressurized spraying, first spray the water mixture of heat-conducting material powder, surface modifier and the first part of adhesive into the fiber slurry; the heat-conducting material powder is tourmaline powder and aluminum oxide powder. The heat-conducting material powder accounts for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com