High-heat-conductive nano fluid adhesive, preparation method of same, and application thereof in production of artificial boards

A nanofluid and adhesive technology, which is applied in the joining of wooden veneers, the preparation of animal glue or gelatin, adhesives, etc., can solve the problems of shortening the curing time of adhesives, and achieve the effect of shortening the hot pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

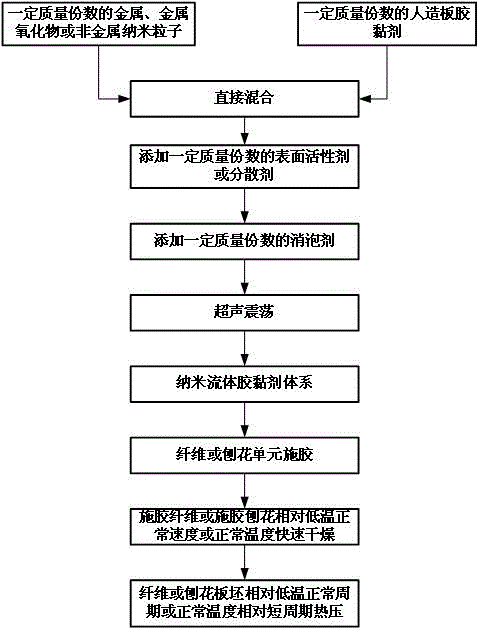

Method used

Image

Examples

Embodiment 1

[0024] Mix nano-copper particles, particle size range 30-60nm, 5 parts (parts by mass, the same below), urea-formaldehyde resin adhesive, 94.7 parts, in the glue mixing tank, and then add anionic surfactant dodecyl Add 0.2 parts of sodium sulfonate, add 0.1 parts of polydimethylsiloxane, install an ultrasonic oscillator in the mixing tank, the ultrasonic frequency is 20kHz, the power is 300W, the working mode is intermittent, work for 3 minutes and stop for 3 minutes to form a dispersion Stable high thermal conductivity nanofluid adhesive system, the thermal conductivity is 31% higher than that of the original urea-formaldehyde resin adhesive. For the production of fiberboard, the sizing first and then drying process is adopted, the sizing method remains unchanged, the sizing fiber adopts the first-stage drying method, the inlet temperature of the fiber dryer drops from 160°C to 140°C, and the drying time remains unchanged for 8s. The dried sizing fiber is hot-pressed after no...

Embodiment 2

[0026] Mix 15 parts (parts by mass, the same below) of iron nanoparticles, with a particle size range of 40-70nm, and 83 parts of melamine-modified urea-formaldehyde resin adhesive, in the glue mixing tank, and then add cationic surfactant ten Add 1 part of hexaalkyldimethylammonium chloride, add 1 part of polydimethylsiloxane, install an ultrasonic oscillator in the glue mixing tank, the ultrasonic frequency is 100kHz, the power is 1500W, the working mode is intermittent, and it works for 4 minutes After stopping for 3 minutes, a dispersed and stable nano-fluid adhesive system with high thermal conductivity is formed, and the thermal conductivity is 51% higher than that of the original melamine-modified urea-formaldehyde resin adhesive. For the production of fiberboard, the sizing method is adopted and the drying process is adopted. The sizing method is unchanged, and the sizing fiber adopts the first-stage drying method. The inlet temperature of the fiber dryer is reduced fro...

Embodiment 3

[0028] Mix 12 parts of nano-aluminum particles with a particle size range of 30-70nm (parts by mass, the same below), and 87 parts of melamine-formaldehyde resin adhesive in the glue mixing tank, and then add the amphoteric surfactant dodecane Add 0.5 parts of sodium aminopropionate, add 0.5 parts of polydimethylsiloxane, install an ultrasonic oscillator in the glue mixing tank, the ultrasonic frequency is 90kHz, the power is 1000W, the working mode is intermittent, work for 4 minutes and stop for 4 minutes, A dispersed and stable nanofluid adhesive system with high thermal conductivity is formed, and the thermal conductivity is 41% higher than that of the original melamine-formaldehyde resin adhesive. For the production of fiberboard, the sizing first and then drying process is adopted, the sizing method remains unchanged, the sizing fiber adopts the first-stage drying method, the inlet temperature of the fiber dryer drops from 160°C to 130°C, and the drying time remains uncha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com