Preparation method of xylogen phenolic resin adhesive

A technology of phenolic resin glue and lignin, which is applied in adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of low wear resistance of phenolic resin adhesives, low safety of phenolic resins, non Environmental protection and other issues, to achieve excellent water resistance and weather resistance, fast curing speed, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

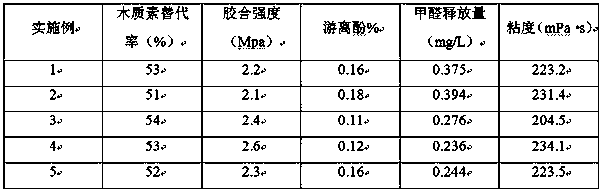

Examples

Embodiment 1

[0039] 1. Preparation of activated lignin

[0040] (1) Take reed stems and leaves, crush them into reed dregs, sprinkle water to moisten them until the water content is 60%, add Tween-80 with 0.05% reed dregs mass, mix them evenly, pack them into bags, and inoculate them with Pseudomonas aeruginosa. After 2 days of aseptic solid-state culture, the cultivation substrate was obtained, and then the cultivation substrate was inoculated with Pteris cerevisiae, and the cultivation was continued for 12 days, and the cultivation temperature was kept at 37°C;

[0041] The Pseudomonas aeruginosa is placed in an Erlenmeyer flask with 20% of the activation medium, the inoculum size is 5%, and the activation culture is carried out at 37°C and 200rpm for 12 hours; the activation medium consists of the following concentration components: Material preparation: rapeseed oil 30g / L, corn steep liquor dry powder 6g / L, NaNO 3 6g / L, K 2 HPO 4 0.9g / L, NaH 2 PO 4 0.6g / L, MgSO 4 0.3g / L, CaCl...

Embodiment 2

[0052] 1. Preparation of activated lignin

[0053] (1) Take reed stems and leaves, crush them into reed dregs, sprinkle water to moisten them until the water content is 70%, add Tween-80 with 0.15% reed dregs mass, mix them evenly, pack them into bags, and inoculate them with Pseudomonas aeruginosa. After 3 days of aseptic solid-state culture, the cultivation substrate was obtained, and then the cultivation substrate was inoculated with Pteris cerevisiae, and the cultivation was continued for 16 days, and the cultivation temperature was kept at 45°C;

[0054] The Pseudomonas aeruginosa is placed in an Erlenmeyer flask with 20% of the activation medium, the inoculum size is 5%, and the activation culture is carried out at 37°C and 200rpm for 16 hours; the activation medium is composed of the following concentration components: Material preparation: rapeseed oil 30g / L, corn steep liquor dry powder 6g / L, NaNO 3 6g / L, K 2 HPO 4 0.9g / L, NaH 2 PO 4 0.6g / L, MgSO 4 0.3g / L, C...

Embodiment 3

[0065] 1. Preparation of activated lignin

[0066] (1) Take reed stems and leaves, crush them into reed dregs, sprinkle water to moisten them until the water content is 65%, add Tween-80 with 0.1% reed dregs mass, mix them evenly, pack them into bags, and inoculate them with Pseudomonas aeruginosa. After 3 days of aseptic solid-state culture, the cultivation substrate was obtained, and then the cultivation substrate was inoculated with Pteris cerevisiae, and the cultivation was continued for 14 days, and the cultivation temperature was kept at 40°C;

[0067] The described Pseudomonas aeruginosa is placed in an Erlenmeyer flask with 20% of the activation medium, the inoculum size is 5%, and the activation culture is carried out at 37° C. and 200 rpm for 14 hours; the activation medium consists of the following concentration components: Material preparation: rapeseed oil 30g / L, corn steep liquor dry powder 6g / L, NaNO 3 6g / L, K 2 HPO 4 0.9g / L, NaH 2 PO 4 0.6g / L, MgSO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com