Shock absorber capable of improving generating efficiency by using suspension magnets under shock absorption working condition

A technology of working state and power generation efficiency, applied in the direction of springs/shock absorbers, electrical components, electromechanical devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

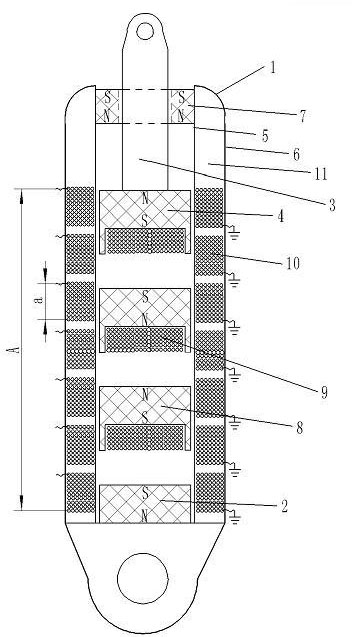

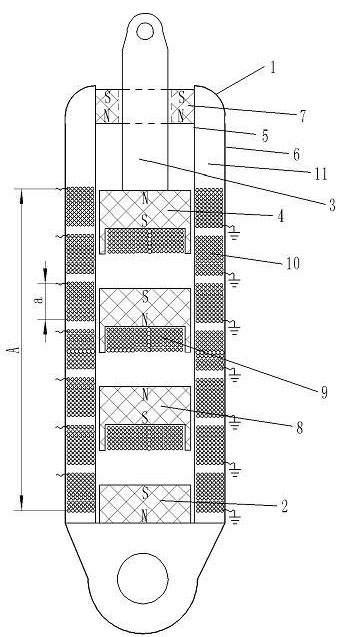

[0037] Embodiment 1, the shock absorber that can improve the power generation efficiency with the levitation magnet in the shock absorbing working state

[0038] Such as figure 1 , the inner layer uses a non-magnetic stainless steel tube with an inner diameter of 1.0 cm as the non-magnetic inner tube 5, and a steel tube mainly used to bear the weight is used as a steel load-bearing tube 6 on the outside, and two tubes that are nested inside and outside are used as a shock absorber The tube body 1. The positioning permanent magnet 2 installed on one end of the tube body 1 and the steel load-bearing tube 6 are fixed and cannot move, and the south pole of the magnetic pole of the positioning permanent magnet 2 faces into the tube body 1; one end of the piston rod is fixed with a piston permanent magnet 4, the piston rod and the piston permanent magnet 4 constitute the piston 3, the piston 3 has a piston permanent magnet 4 and one end is placed in the non-magnetic material inner ...

Embodiment 2

[0047] Embodiment 2, the piston permanent magnet is that the south pole faces the positioning permanent magnet, and both sides of the suspension permanent magnet have closed and loop coils, and the suspension magnet can improve the shock absorber of the power generation efficiency in the shock absorbing working state.

[0048]On the basis of Embodiment 1, the piston 3 , the first suspended permanent magnet 8 and the second suspended permanent magnet 8 are taken out from the inner tube 5 made of non-magnetic material. The magnetic poles in the upper direction of the first suspended permanent magnet 8 and the second suspended permanent magnet 8 are also bonded with closed and loop coils 9 .

[0049] The magnet north face of the first suspended permanent magnet 8 is bonded with a closed and loop coil 9 , and the winding direction of the closed and loop coil 9 is clockwise winding as viewed from the side of the closed and loop coil 9 . A closed and loop coil 9 is bonded to the mag...

Embodiment 3

[0053] Embodiment 3: The closed and loop coil will not rub against the inner tube of non-magnetic material. The suspension magnet can improve the power generation efficiency in the shock absorbing working state.

[0054] On the basis of embodiment 1, the south pole face of the 4 magnetic poles of the piston permanent magnet, the south pole face of the 8 magnetic poles of the first suspended permanent magnet, and the north pole surface of the magnetic pole of the second suspended permanent magnet 8 are made inwardly recessed by 0.4 cm Structure.

[0055] Closed and loop coil 9 is not used the kind of coil of embodiment 1, but uses the double-layer plate that copper film layer is arranged on the insulating substrate instead, copper film layer is corroded into the closed loop coil single that has multiple concentric rings on the same plane layer winding. In the 0.4 cm concave structure of each permanent magnet, multiple single-layer windings of closed loop coils are laminated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com