Novel hot melt adhesive and preparation method thereof

A hot-melt adhesive, a new type of technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of unfavorable large-scale application, low interface bonding strength, and low bonding strength, and achieve Suitable for large-scale industrial production, good bonding effect, and low hot pressing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

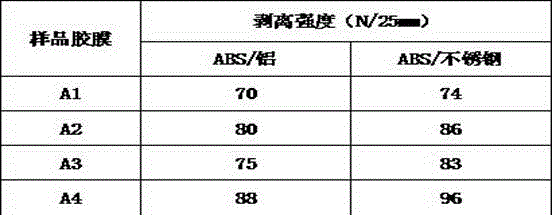

Examples

Embodiment 1

[0023] Preparation of nylon-type copolyamide: 113.16g caprolactam (1mol), 234.73g nylon 66 salt (0.895mol), 273.02g nylon 1010 salt (0.737mol), 6.74g stearic acid (0.0237mol) and 100g deionized water, add into a 2L high-pressure reactor with a stirrer, a thermometer and a pressure gauge; after the feeding is completed, replace it with nitrogen and evacuate to remove the air in the reactor; then fill it with 0.2MPa high-purity nitrogen, and heat slowly Slowly raise the temperature to 250°C, under the pressure of 1.8MPa, heat preservation reaction for 2 hours, slowly reduce the pressure to normal pressure, and continue to depressurize to 0.05MPa after dehydration for 1 hour; discharge and pelletize to obtain granular nylon-type copolyamide ( PA-1).

[0024] Preparation of new hot melt adhesive: 400g PA-1, 400g thermoplastic polyurethane (melting point is 100°C, melt index is 40g / 10min / 2.16kg / 190°C), 5g maleic anhydride grafted polyethylene-vinyl acetate (grafted Branch rate 2%)...

Embodiment 2

[0027] Preparation of nylon-type copolyamide: After mixing 116.14g of caprolactam (1.026mol), 220.93g of nylon 66 salt (0.842mol) and 282.77g of nylon 1010 salt (0.763mol), add it to a In a 2L high-pressure reactor; add 7.49g stearic acid (0.0263mol) and 100g deionized water, replace with nitrogen and evacuate to remove the air in the reactor; then fill with 0.2MPa high-purity nitrogen, heat Slowly raise the temperature to 230°C, under the pressure of 1.0-1.2MPa, keep warm for 3 hours, slowly depressurize to normal pressure, and continue to depressurize to 0.05MPa for 1 hour after dehydration; discharge and granulate to obtain granular nylon type Copolyamide (PA-2).

[0028] Preparation of new hot melt adhesive: 435g PA-2, 435g thermoplastic polyurethane (melting point is 80°C, melt index is 45g / 10min / 2.16kg / 190°C), 7g maleic anhydride grafted polyethylene-vinyl acetate (grafted rate 2.3%), 112g thermoplastic phenolic resin, 10g calcium carbonate, 1g antioxidant BHT (2,6-di-t...

Embodiment 3

[0031] Preparation of nylon-type copolyamide: After mixing 116.14g of caprolactam (1.026mol), 262.35g of nylon 66 salt (1mol), and 224.27g of nylon 1010 salt (0.605mol), add it to a tank with agitator, temperature gauge and pressure gauge 2L high-pressure reactor; then add 8.23g stearic acid (0.0289mol) and 100g deionized water, replace with nitrogen and evacuate to remove the air in the reactor; then fill with 0.2MPa high-purity nitrogen, heat slowly Slowly raise the temperature to 230°C, under the pressure of 1.0-1.2MPa, heat preservation reaction for 3 hours, slowly reduce the pressure to normal pressure, and continue to reduce the pressure to 0.05MPa after dehydration for 1 hour; discharge and pelletize to obtain granular nylon copolymer Amide (PA-3).

[0032] Preparation of new hot melt adhesive: 440g PA-3, 440g thermoplastic polyurethane (melting point: 88°C, melt index: 42g / 10min / 2.16kg / 190°C), 9g polyolefin grafted with maleic anhydride (grafting rate: 1.2%) , 58g ter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com