Novel hot-melt adhesive and preparation method thereof

A hot-melt adhesive and hot-melt adhesive film technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problem of metal bonding and weak adhesive bonding that have been rarely studied , Bonding strength is not high, to achieve the effect of high bonding strength, short time, low hot pressing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

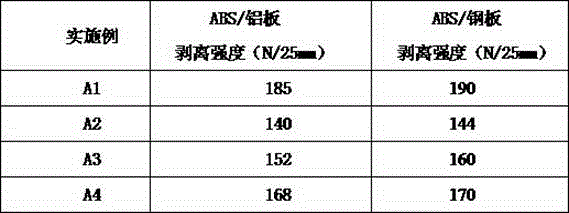

Examples

Embodiment 1

[0022] Preparation of nylon-type copolyamide: 113.16g caprolactam (1mol), 224.87g nylon 66 salt (0.857mol), 545.14g nylon 610 salt (1.714mol), 10.16g stearic acid (0.0357mol) and 100g deionized water, add into a 2L high-pressure reactor with a stirrer, a thermometer and a pressure gauge; after the feeding is completed, replace it with nitrogen and evacuate to remove the air in the reactor; then fill it with 0.2MPa high-purity nitrogen, and heat slowly Slowly raise the temperature to 250°C, under the pressure of 1.8MPa, keep it warm for 2 hours, slowly reduce the pressure to normal pressure, and continue to depressurize to 0.05MPa for 1 hour after dehydration; then discharge to obtain nylon-type copolyamide (PA-1) .

[0023] To prepare a new type of composite hot-melt adhesive, 450g of nylon-type copolyamide (PA-1), 350g of thermoplastic polyurethane (melting point is 100°C, melting index is 40g / 10min / 2.16kg / 190°C), 3g of polyethylene-terminated epoxy wax (Epoxy functionality ...

Embodiment 2

[0026] Preparation of nylon-type copolyamide: 121.24g caprolactam (1.071mol), 262.35g nylon 66 salt (1mol), 477g nylon 610 salt (1.5mol), 10.16g stearic acid (0.0357mol) and 100g deionized water were added to In a 2L high-pressure reactor with a stirrer, a thermometer and a pressure gauge; after the feeding is completed, replace it with nitrogen and evacuate to remove the air in the reactor; then fill it with 0.2MPa high-purity nitrogen, and heat it slowly Raise the temperature to 250°C, under the pressure of 1.8MPa, keep warm for 2h, slowly depressurize to normal pressure, and continue to depressurize to 0.05MPa for 1h after dehydration; discharge and pelletize to obtain granular nylon-type copolyamide (PA-2 ).

[0027] Preparation of new hot melt adhesive: 480g dimer acid copolyamide, 370g thermoplastic polyurethane (melting point 80°C, melt index 45g / 10min / 2.16kg / 190°C), 7g polyethylene-terminated epoxy wax (epoxy functional 1), 132g terpene resin, 10g kaolin, 1g antioxida...

Embodiment 3

[0030] Preparation of nylon-type copolyamide: 117.2g caprolactam (1.036mol), 215.5g nylon 66 salt (0.821mol), 545.14g nylon 610 salt (1.714mol), 11.18g stearic acid (0.0393mol) and 100g deionized water, Add it into a 2L high-pressure reactor equipped with a stirrer, a thermometer and a pressure gauge; after the feeding is completed, replace it with nitrogen and evacuate it to remove the air in the reactor; then fill it with 0.2MPa high-purity nitrogen and heat Slowly raise the temperature to 250°C, under the pressure of 1.8MPa, heat preservation reaction for 2h, slowly reduce the pressure to normal pressure, and continue to depressurize to 0.05MPa after dehydration for 1h; discharge and pelletize to obtain granular nylon-type copolyamide (PA -3).

[0031] Preparation of new hot melt adhesive: 500g dimer acid copolyamide, 340g thermoplastic polyurethane (melting point is 88°C, melt index is 42g / 10min / 2.16kg / 190°C), 9g epoxy functional polyolefin elastomer (epoxy functional 1),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com