Aldehyde-free low-cost polysaccharide adhesive and preparation method thereof

A low-cost polysaccharide glue technology, applied in polysaccharide adhesives, adhesives, adhesive additives, etc., can solve the problems of poor water resistance and bonding performance, and achieve the effects of enhancing bonding performance, balancing internal stress, and reducing particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A method for preparing an aldehyde-free and low-cost polysaccharide adhesive, characterized in that it comprises the following steps:

[0055] (1) Weigh each component according to the weight ratio, mix the nanofibers grafted with methylolmelamine and dispersion medium water, and ultrasonically disperse for 15 minutes;

[0056](2) Add the hyperbranched amino polysaccharide to the solution of (1), pass the mixed solution through a high-pressure homogenizer, and homogenize for 15 minutes under a pressure of 70 MPa;

[0057] (3) Add multifunctional epoxy compound and polyacrylamide to the mixture obtained in step (2) successively, and stir evenly.

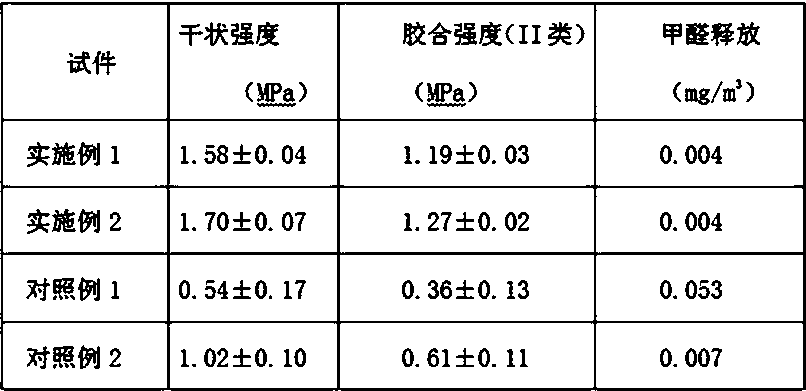

Embodiment 1

[0059] This embodiment provides a preparation method of a polysaccharide adhesive, and the adhesive is prepared according to the following weight ratio:

[0060] Hyperbranched amino polysaccharides 20 kg

[0061] Multifunctional epoxy compound 6 kg

[0062] Nanofibers grafted with methylol melamine 1 kg

[0063] Polyacrylamide 1 kg

[0064] This embodiment also provides the preparation method of the above-mentioned adhesive, and the specific preparation steps are the same as the above-mentioned preparation method.

Embodiment 2

[0066] This embodiment provides a preparation method of a polysaccharide adhesive, and the adhesive is prepared according to the following weight ratio:

[0067] Hyperbranched Glycan 25 kg

[0068] Multifunctional epoxy compound 16 kg

[0069] Nanofibers grafted with methylolmelamine 2 kg

[0070] Polyacrylamide 3 kg

[0071] The preparation method of the adhesive described in this embodiment is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com