A high water -resistant, low -mode volume single -component MS sealing, preparation method and application

A technology of MS sealant and low modulus, applied in the field of sealant, can solve the problems of incomplete degassing, uneven mixing, insufficient waterproof performance of seam sealing, etc., and avoid the complexity of on-site construction management and supporting mechanical equipment , Excellent adhesion and sealing and waterproof performance, excellent adhesion and displacement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A high water resistance, low modulus one-component MS sealant, comprising the following components by weight:

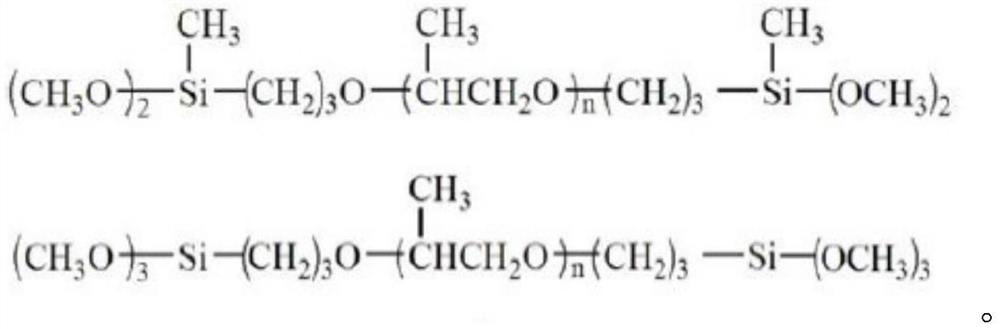

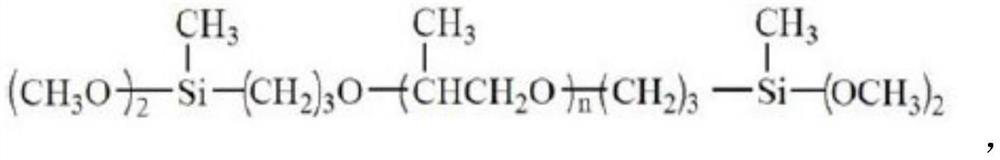

[0047] Basic MS Resins: Molecular Structure

[0048]

[0049] The number average molecular weight is 10000, 50 parts;

[0050] Plasticizer, isononyl cyclohexane-1,2-dicarboxylate (DINCH), 50 parts;

[0051] Inorganic filler, ground calcium carbonate and talcum powder, 150 parts;

[0052] Thixotropic agent, hydrogenated castor oil, 10 parts;

[0053] Weather resistance agent, salicylate UV absorber, benzophenone UV absorber, 8 parts;

[0054] Catalyst, stannous octoate, two (dodecyl sulfide) dibutyl tin, 1 part;

[0055] MS sealant color masterbatch, composed of titanium dioxide, carbon black and diisodecyl phthalate (DIDP) in a mass ratio of 2:1:7, 3 parts;

[0056] Water-resistant adhesive, 5 parts, wherein, described water-resistant adhesive comprises following component, by molar mass part:

[0057] Trifunctional aminosilane coupling agent, γ-amino...

Embodiment 2

[0061] A high water resistance, low modulus one-component MS sealant, comprising the following components by weight:

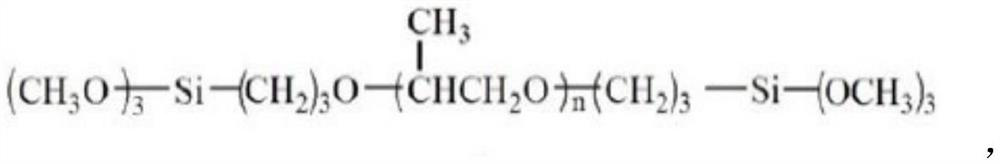

[0062] Basic MS resin: the molecular structure is:

[0063]

[0064] The number average molecular weight is 10000-28000, 20 parts;

[0065] Plasticizer, diisodecyl phthalate (DIDP), 20 parts;

[0066] Inorganic filler, light calcium carbonate, silicon micropowder, 50 parts;

[0067] Thixotropic agent, fumed silica, organic bentonite, 3 parts;

[0068] Weather resistance agent, hindered amine light stabilizer, 2 parts;

[0069] Catalyst, dibutyltin diacetate, 0.05 part;

[0070] Color masterbatch for MS sealant, composed of titanium dioxide, carbon black and diisodecyl phthalate (DIDP) at a mass ratio of 2:1:7, 0.5 parts;

[0071] Water-resistant adhesive, 1 part, wherein, the water-resistant adhesive includes the following components, in parts by molar mass:

[0072] Trifunctional aminosilane coupling agent, γ-aminopropyltriethoxysilane, N-β-(aminoeth...

Embodiment 3

[0075] Basic MS resin, 25 parts;

[0076] Plasticizer, diisononyl phthalate (DINP), 25 parts;

[0077] Inorganic filler, nano active calcium carbonate, 50 parts;

[0078] Thixotropic agent, polyamide wax, 5 parts; Weather resistance agent, 2 parts;

[0079] MS sealant color masterbatch, 2 parts;

[0080] Water-resistant adhesive, the water-resistant adhesive of embodiment 1, 2 parts;

[0081] Catalyst, dibutyltin dilaurate, 0.5 parts.

[0082] The preparation method of the high water resistance and low modulus one-component MS sealant described in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com