A kind of formaldehyde-free soybean gum and preparation method thereof

A technology of formaldehyde-free bean gum and aldehyde bean gum, applied in the preparation of animal glue or gelatin, adhesives, non-polymer adhesive additives, etc., can solve the problem of uneven distribution of cross-linked structure of protein adhesives, artificial bonding Formaldehyde release from panels, inability to use wood-based panels for outdoor use, etc., to achieve the effect of increasing types and quantities, decreasing weak interface layer, and improving adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

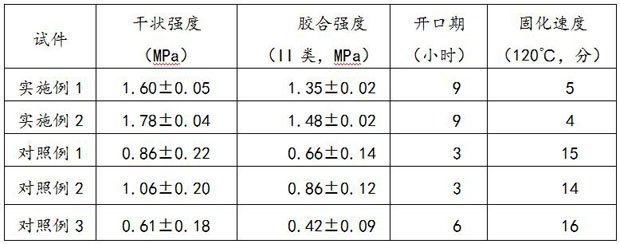

Examples

Embodiment 1

[0046] A formaldehyde-free soybean gum, consisting of the following raw materials by weight:

[0047] Demineralized water 70kg;

[0048] Soybean meal protein powder 35kg;

[0049] Trypsin 0.1kg;

[0050] Soybean chitinase 0.1kg;

[0052] Triethylenetetramine 0.2kg;

[0053] Ethylene glycol diglycidyl ether 0.3kg;

[0054] Curing agent 0.3kg.

[0055] When using the formaldehyde-free bean gum in this embodiment: Stir the bean gum prepolymer and the curing agent at room temperature for 10 minutes, and stir evenly before use.

Embodiment 2

[0057] A formaldehyde-free soybean gum, consisting of the following raw materials by weight:

[0058] Demineralized water 70kg;

[0059] Soybean meal protein powder 35kg;

[0060] Trypsin 0.3kg;

[0061] Soybean chitinase 0.3kg;

[0063] Triethylenetetramine 0.5kg;

[0064] Ethylene glycol diglycidyl ether 0.8kg;

[0065] Curing agent 0.8kg.

Embodiment 3

[0067] A preparation method of formaldehyde-free bean gum, comprising the following steps:

[0068] (1) According to the weight ratio in the above-mentioned formaldehyde-free soybean gum, weigh each component and prepare raw materials;

[0069] (2) Evenly disperse the soybean meal powder, water and trypsin in the dispersion medium water, raise the temperature of the water bath to 40°C, stir for 30 minutes, then raise the temperature to 80°C for 10 minutes to inactivate the enzyme;

[0070] (3) Cool down the mixture obtained in step 2 to 40°C, add chitosinase, keep it warm for 15 minutes, then raise the temperature to 80°C to kill the enzyme;

[0071] (4) Add sodium periodate to the mixture obtained in step 3, raise the temperature to 50°C, adjust the pH value to 4.0, add triethylenetetramine to react at 50°C for 2 hours after reacting for 5 hours, then raise the temperature to 90°C, and react for 6 hours ;

[0072] (5) Heat up the mixture in step 4 to 80°C, adjust the pH val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com