A low-cost formaldehyde-free soybean meal adhesive and its preparation method

A technology of adhesive and aldehyde soybean meal, which is applied in the field of low-cost formaldehyde-free soybean meal adhesive and its preparation, can solve the problems of poor water-resistant bonding performance and free formaldehyde release of wood-based panels, etc., and achieve good water-resistant bonding performance, Improved adhesive performance and high crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

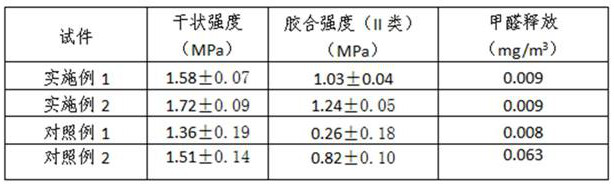

Examples

Embodiment 1

[0036] This embodiment provides a method for preparing a soybean meal protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0037] Modified soybean meal 30 kg

[0038] Polyacrylamide 0.1kg

[0039] Surface Modified Nanocellulose 1.0kg

[0040] This embodiment provides a preparation method of soybean meal-based adhesive, comprising the following steps:

[0041] (1) Weigh the components according to the weight ratio, add the surface-modified nanocellulose into the dispersion medium water, ultrasonicate for 15 minutes, and then add half the weight of modified soybean meal, use a high-pressure homogenizer, under 30MPa pressure and 0.5MPa Under the action of emulsifying force, homogeneously emulsify for 20 minutes;

[0042] (2) Add the remaining modified soybean meal to the mixture obtained in step (1), mix well, add sodium hydroxide to adjust pH=9.0, react at 80°C for 20min, cool down to 30°C and discharge.

Embodiment 2

[0044] This embodiment provides a method for preparing a soybean meal protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0045] Modified soybean meal 33 kg

[0046] Polyacrylamide 0.2kg

[0047] Surface Modified Nanocellulose 2.0kg

[0048] The preparation method of the adhesive described in this embodiment is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com